Hot blast stove

A technology of hot blast stove and furnace, which is applied in the field of boilers, can solve the problems of low boiler heat utilization rate and polluted air, and achieve the effect of simple structure, large heating area and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

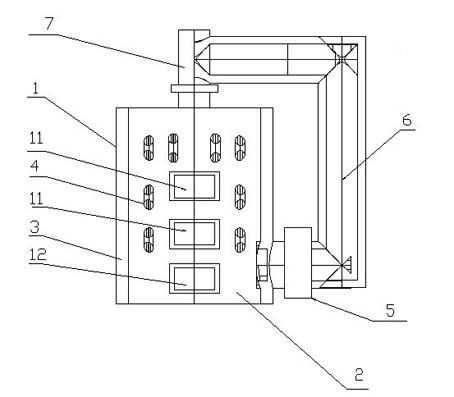

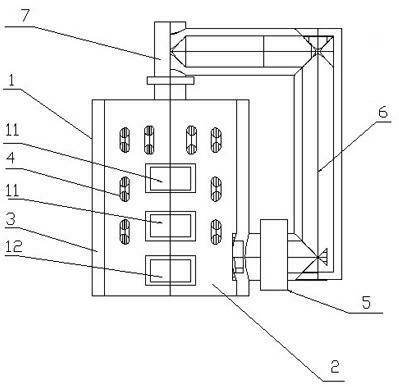

[0011] Such as figure 1 As shown, a hot blast stove includes a furnace shell 1 and a furnace 2 installed in the furnace shell, the outer wall of the furnace 2 is provided with a water interlayer 3, and the furnace shell is provided with a coal filling port 11 and an ash outlet 12 leading to the furnace , a multilayer superconductor 4 is obliquely installed in the furnace, and the two ends of the superconductor 4 communicate with the water interlayer 3, and an induced draft fan 5 is arranged at the bottom of the furnace 2, and the induced draft fan 5 is connected to the inlet at the top of the furnace through the induced draft duct 6. The tuyere 7 is connected.

[0012] When in use, coal is added through the coal filling port of the boiler, and the coal burns on the superconductor, and the induced draft fan is activated to form a top-to-bottom hot air circulation in the furnace, which reduces the air pollution caused by coal combustion, and passes through the obliquely installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com