Nano-aperture granular adsorbent and preparation and application thereof

A granular and adsorbent technology, applied in the field of nano-pore granular adsorbent, can solve the problems of secondary pollution of drinking water, easy residual solid particles, complicated preparation process, etc., achieve strong hygroscopicity, save closed equipment and electric energy, Resourceful Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) take by weighing 3g the bentonite and chitosan mixture that ratio is 1: 1, mix homogeneously; (2) add above-mentioned mixture into the acetic acid dissolving solution of 1.2% (w / w) and dissolve into thick thing; (3) Slowly drop the above-mentioned thick matter into 50mL of alkaline solidified liquid composed of 40% (w / w) sodium hydroxide and absolute ethanol in a volume ratio of 1:5 to form spherical particles; (4) the molded The adsorbent is rinsed with distilled water to neutrality, and after drying, the finished product of nano-pore granular adsorbent is obtained.

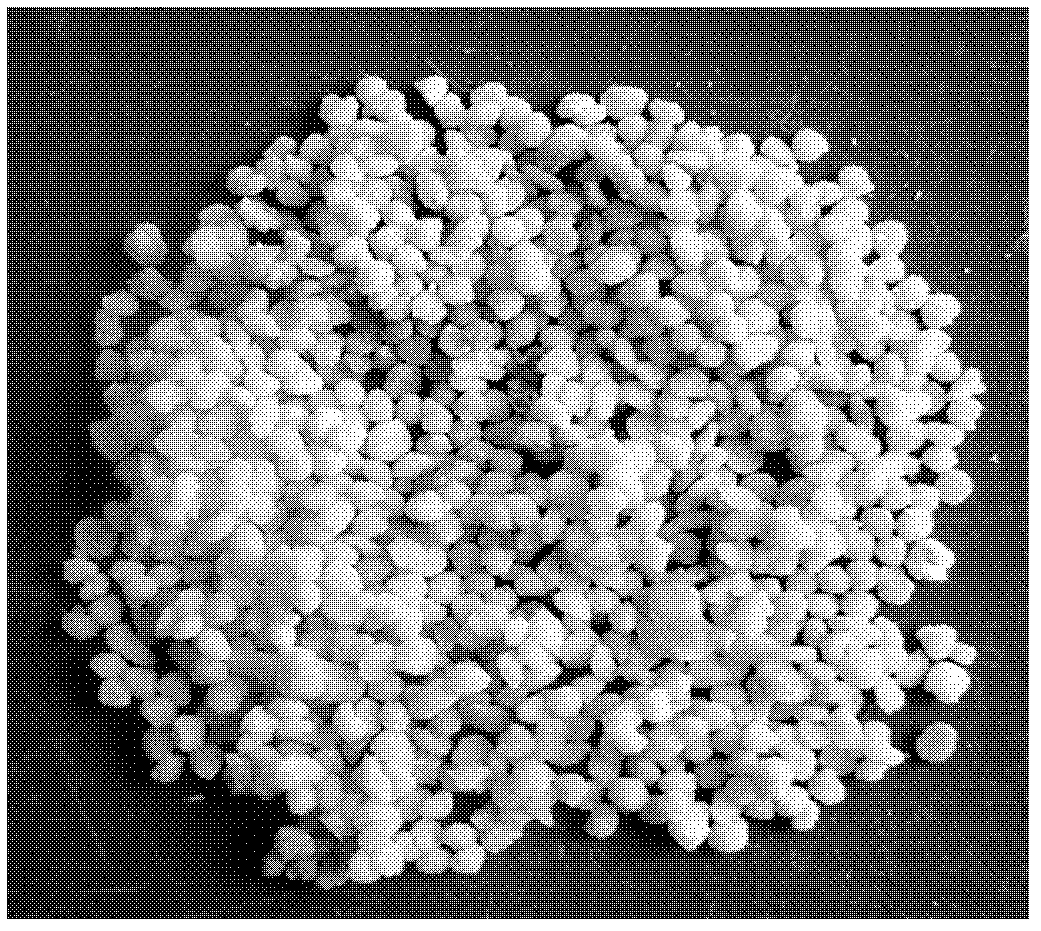

[0027] figure 1 The finished effect of the nanoporous granular adsorbent prepared for Example 1.

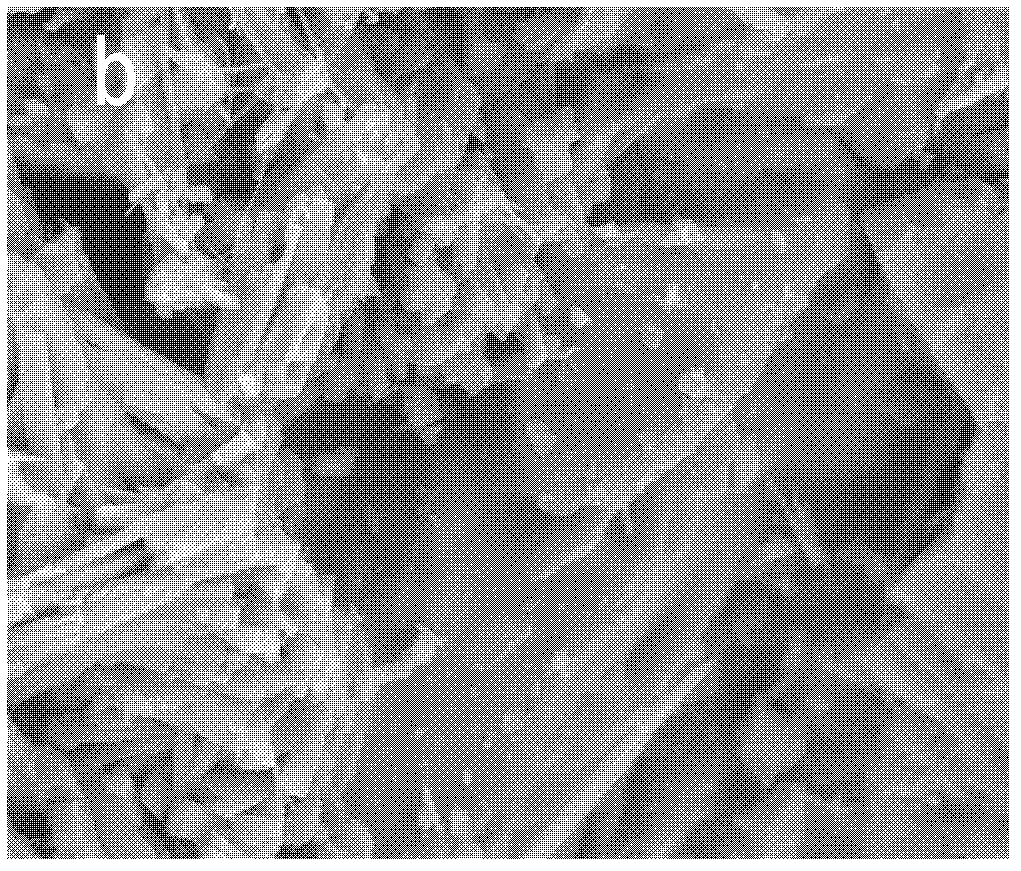

[0028] figure 2 The scanning electron micrograph of the adsorbent prepared in Example 1 shows that the adsorbent has a high surface roughness (3000 times magnification) and a large pore volume, which is conducive to the adsorption of heavy metals and organic matter.

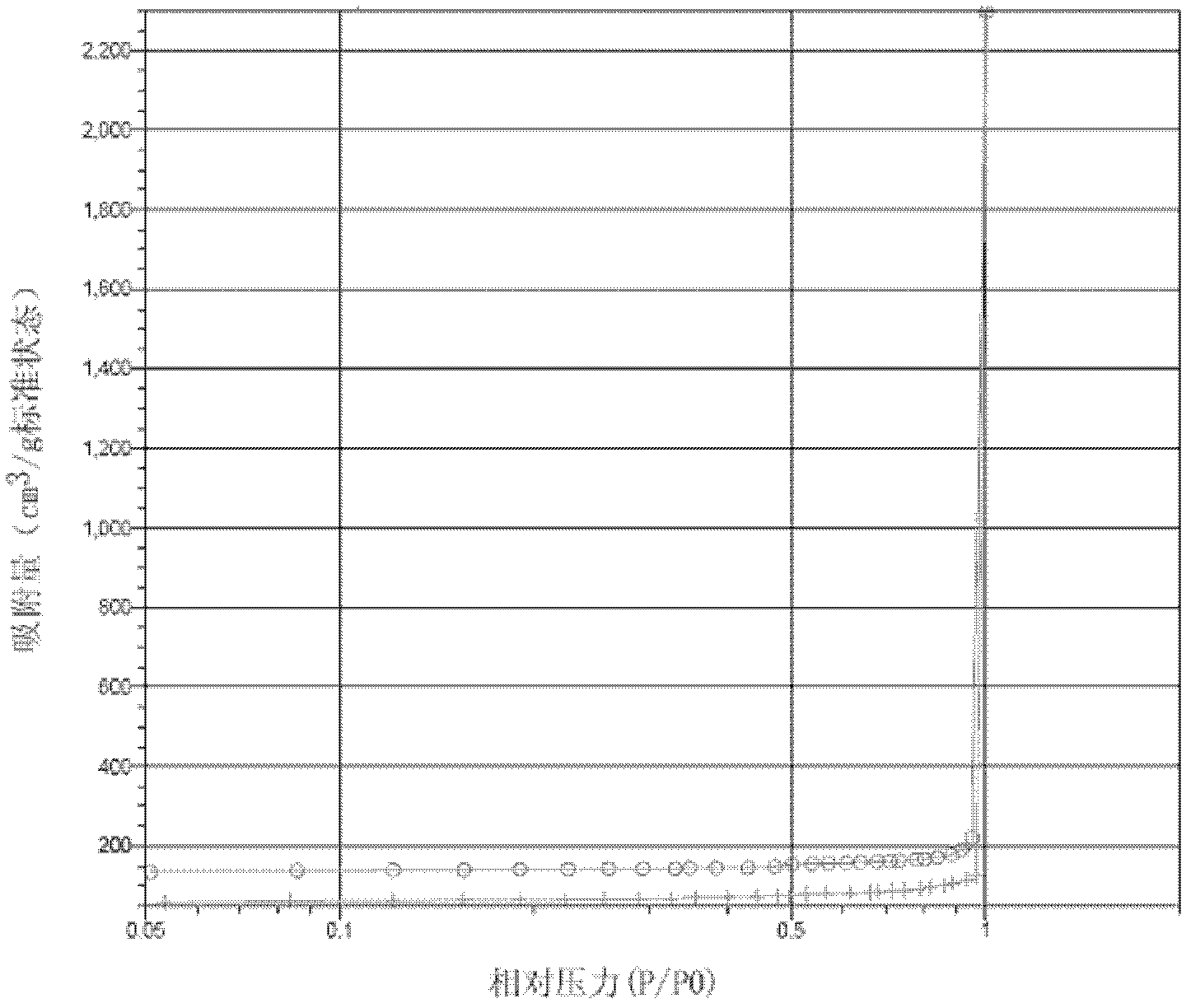

[0029] image 3 N of the adsorb...

Embodiment 2

[0031] (1) Take by weighing 3g of bentonite and chitosan mixture with a ratio of 1:3, mix uniformly; (2) add the above-mentioned mixture to 1.2% acetic acid solution and dissolve it into a thick thing; (3) mix the above-mentioned thick thing Slowly drop into 80mL of alkaline solidified solution composed of 40% sodium hydroxide and absolute ethanol in a volume ratio of 1:10 to form spherical particles; (4) rinse the formed adsorbent with distilled water until neutral, and dry After that, the finished product of the nano-pore granular adsorbent is obtained.

Embodiment 3

[0033] (1) Take by weighing 3g of bentonite and chitosan mixture with a ratio of 1:8, mix uniformly; (2) add the above-mentioned mixture to 1.2% acetic acid dissolving solution and dissolve into a thick thing; (3) mix the above-mentioned thick thing Slowly drop into 100mL of alkaline solidified solution composed of 40% sodium hydroxide and absolute ethanol in a volume ratio of 1:15 to form spherical particles; (4) Rinse the formed adsorbent with distilled water until neutral, and dry After that, the finished product of the nano-pore granular adsorbent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com