Device and method for screening coal powder in grain level being lower than 0.5 mm

A screening device and pulverized coal technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of insufficient screening, large errors in screening results, large human factors, etc., and achieve screening The method is simple and easy to operate, and the effect of avoiding accumulation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

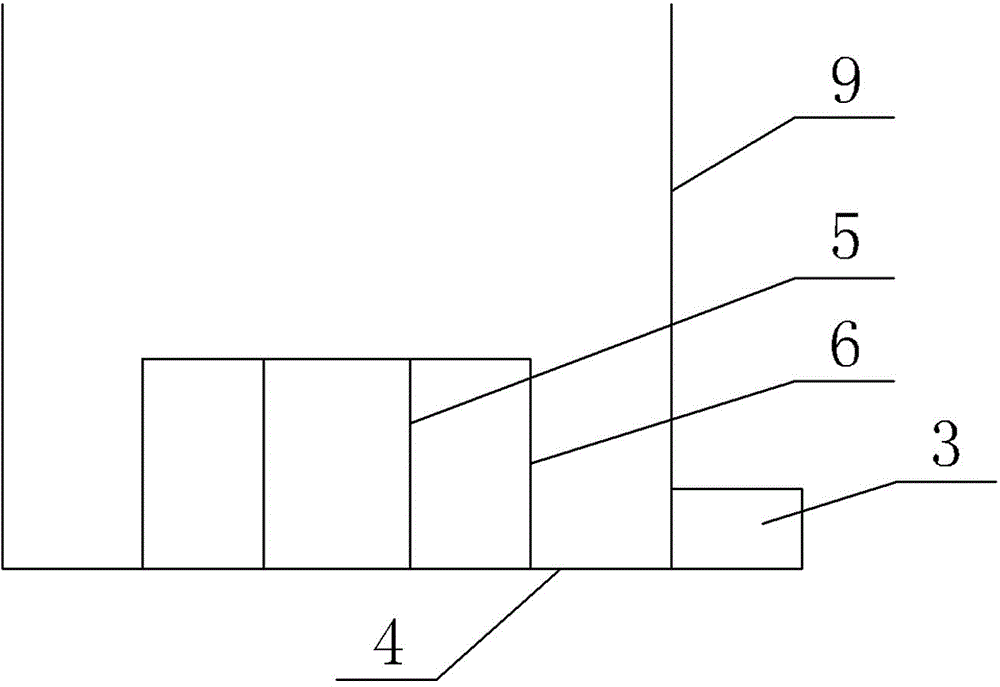

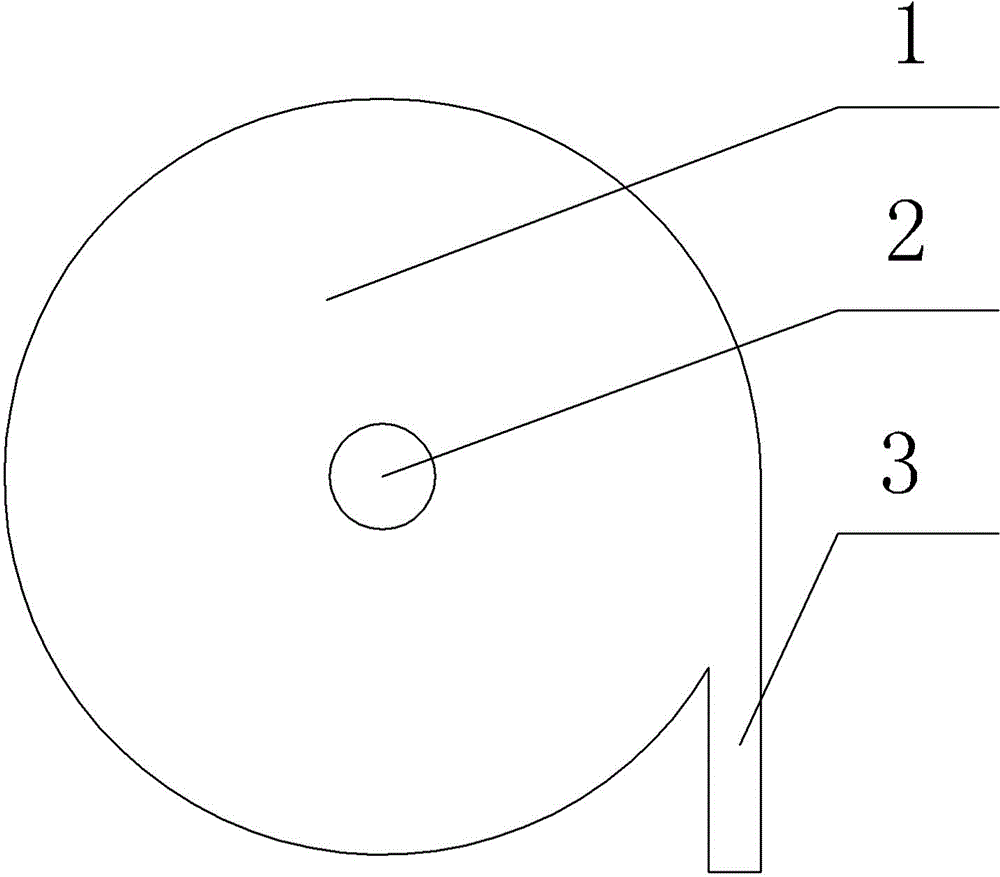

[0020] Such as figure 1 As shown, a screening device for pulverized coal with a particle size below 0.5 mm, the screening device includes a barrel-shaped container surrounded by a bottom surface 4 and a side wall 9, and the barrel-shaped container is sequentially set with two Layer screen drum, the innermost screen drum is the first screen drum 5, the second screen drum 6 is set outside the first screen drum 5, the screen hole size of the first screen drum 5 is 0.5mm, the second screen drum 6 The size of the sieve hole is 0.25mm, wherein the inner cavity of the first sieve drum 5 is the feeding cavity, and the side wall 9 of the barrel-shaped container is provided with a water outlet 3 .

Embodiment 2

[0022] Adopt the screening method of the screening device of embodiment 1, may further comprise the steps:

[0023] (1) Put the coal powder to be screened into the inner cavity of the first screen cylinder 5 of the screening device;

[0024] (2) Inject water into the inner cavity of the first sieve cylinder 5, and the pulverized coal to be screened is dispersed and moved around under the agitation of the water flow, passing through the first sieve cylinder 5 and the second sieve cylinder 6 in turn, and the coal powder of different particle sizes The pulverized coal stays or passes through the sieve drum, and finally achieves the purpose of grading and screening.

Embodiment 3

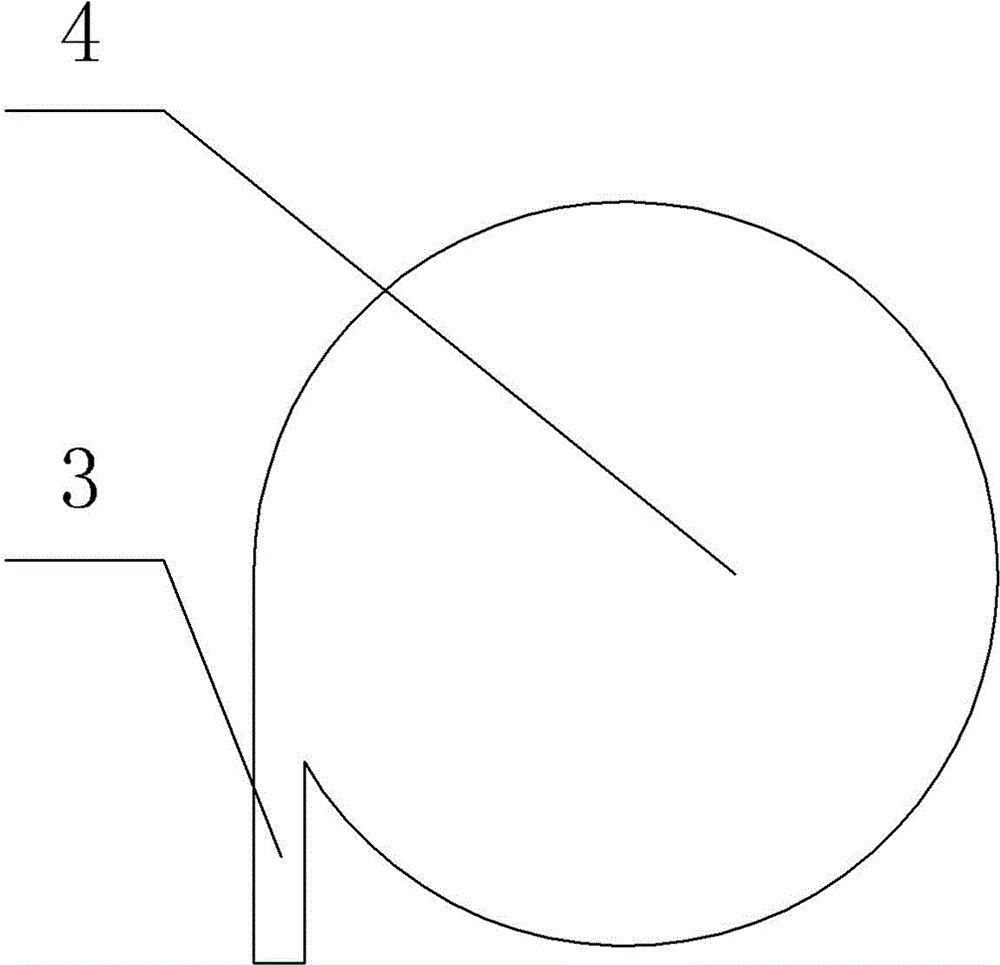

[0026] as attached figure 2 ~ attached Figure 5 As shown, a screening device for pulverized coal with a particle size below 0.5 mm, the screening device includes a barrel-shaped container surrounded by a bottom surface 4 and a side wall 9, inside the barrel-shaped container there are four sets of The innermost layer is the first sieve cylinder 5, the second sieve cylinder 6, the third sieve cylinder 7 and the fourth sieve cylinder 8 from inside to outside, the first sieve cylinder 5, the second sieve cylinder 6, the second sieve cylinder The mesh sizes of the three sieve cylinders 7 and the fourth sieve cylinder 8 are respectively 0.5mm, 0.25mm, 0.125mm, and 0.045mm, wherein the inner cavity of the first sieve cylinder is the feeding cavity, and the side wall 9 of the barrel-shaped container is provided with Water outlet 3, the water outlet direction of water outlet 3 is the tangential direction of the side wall 9 of the barrel-shaped container, the upper part of the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com