Preparation method for high-performance manganese zinc ferrite powder

A high-performance manganese-zinc and manufacturing method technology, which is applied in the field of wet manufacturing of manganese-zinc ferrite powder, can solve the problems of powder change, affecting performance, particle size and moisture content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Molebi Fe 2 o 3 : 55%, ZnO: 6.8%, NiO: 1.5%, the rest is MnO ratio converted to mass percentage feeding, MnO converted to Mn 3 o 4 , the raw material initial D50 particle size is: Fe 2 o 3 : 1.4μm; ZnO: 1.0μm; Mn 3 o 4 : 1.2 μm; NiO: 1.2 μm.

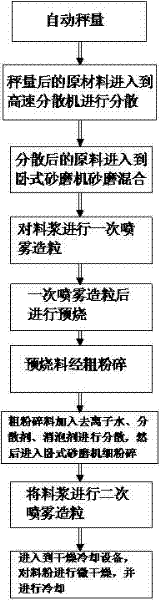

[0043]as attached figure 1 As shown, after being dispersed by the method of the present invention and mixed by horizontal sand milling, the particle size of the mixture is D50: 0.8 μm, D90: 1.3 μm. After one spray granulation, the chloride ion content of the pre-burned material is 60ppm, after coarse crushing D50: 1.5μm, D90: 4.5μm, after fine grinding by horizontal sand mill D50: 1.0μm, D90: 2.5μm, fine Add SiO when pulverizing 2 , CaCO 3 , Nb 2 o 5 、Co 3 o 4 , ZrO, Ta 2 o 5 , V 2 o 5 、 Bi 2 o 3 、TiO 2 One or several of them are added with PVA, followed by secondary spray granulation, drying and freezing, and the moisture content of the powder is 0.02% to 0.025%.

[0044] Press the powder prepared above into...

Embodiment 2

[0047] Molebi Fe 2 o 3 : 52%, ZnO: 18.5%, the rest is the ratio of MnO converted to mass percentage feeding, MnO converted to Mn 3 o 4 , the raw material initial D50 particle size is: Fe 2 o 3 : 1.4μm; ZnO: 1.0μm; Mn 3 o 4 : 1.2 μm; NiO: 1.2 μm.

[0048] as attached figure 1 As shown, after dispersion and horizontal sand milling by the method of the present invention, the particle size of the mixture is D50: 0.8 μm, D90: 1.2 μm. After a spray granulation, the chloride ion content of the pre-burned material is 40ppm, after coarse crushing D50: 1.5μm, D90: 4.5μm, finely crushed by a horizontal sand mill D50: 0.8μm, D90: 2μm, finely crushed SiO 2 , CaCO 3 , Nb 2 o 5 、Co 3 o 4 , ZrO, Ta 2 o 5 , V 2 o 5 、 Bi 2 o 3 、TiO 2 One or several of them are added with PVA, followed by secondary spray granulation, drying and freezing, and the moisture content of the powder is 0.02% to 0.025%. Press the powder prepared above into a circular sample with an outer diameter o...

Embodiment 3

[0051] Molebi Fe 2 o 3 : 53%, ZnO: 10.5%, the rest is the ratio of MnO converted to mass percentage feeding, MnO converted to Mn 3 o 4 , the raw material initial D50 particle size is: Fe 2 o 3 : 1.4μm; ZnO: 1.0μm; Mn 3 o 4 : 1.2 μm; NiO: 1.2 μm.

[0052] as attached figure 1 As shown, after dispersion and horizontal sand milling by the method of the present invention, the particle size of the mixture is D50: 0.8 μm, D90: 1.2 μm. After a spray granulation, the chloride ion content of the pre-burned material is 40ppm, after coarse crushing D50: 1.5μm, D90: 4.5μm, after fine grinding by horizontal sand mill D50: 0.9μm, D90: 2.5μm, fine Add SiO when pulverizing 2 , CaCO 3 , Nb 2 o 5 、Co 3 o 4 , ZrO, Ta 2 o 5 , V 2 o 5 、 Bi 2 o 3 、TiO 2 One or several of them are added with PVA, followed by secondary spray granulation and drying and freezing. The moisture content of the powder is 0.02% to 0.025%. The powder prepared above is pressed into an outer diameter of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com