Water level control circuit used for heating purified water and heating container

A technology of water level control and pure water, applied in the direction of liquid level control, fluid heater, non-electric variable control, etc. It can solve the problems of water overflow, water level control device failure, high resistance pure water level monitoring and control, etc. problem, to achieve the effect of reducing corrosion, good applicability, and reducing ionization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

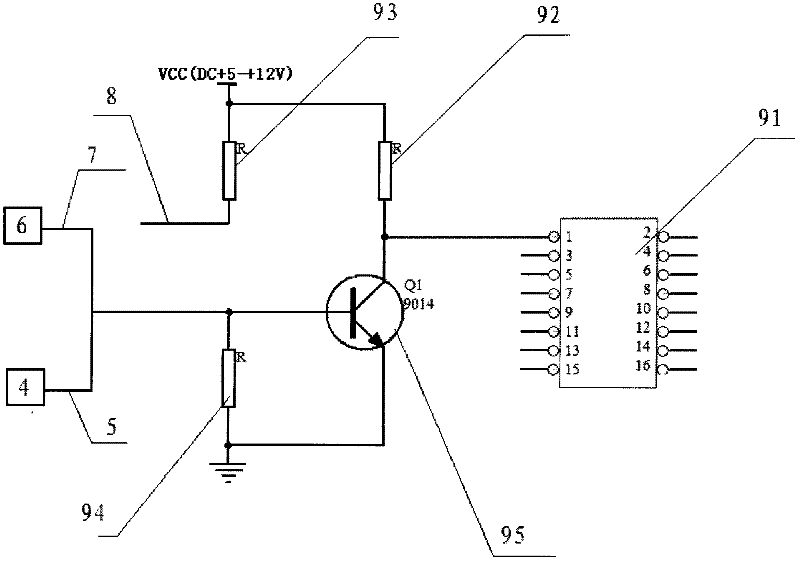

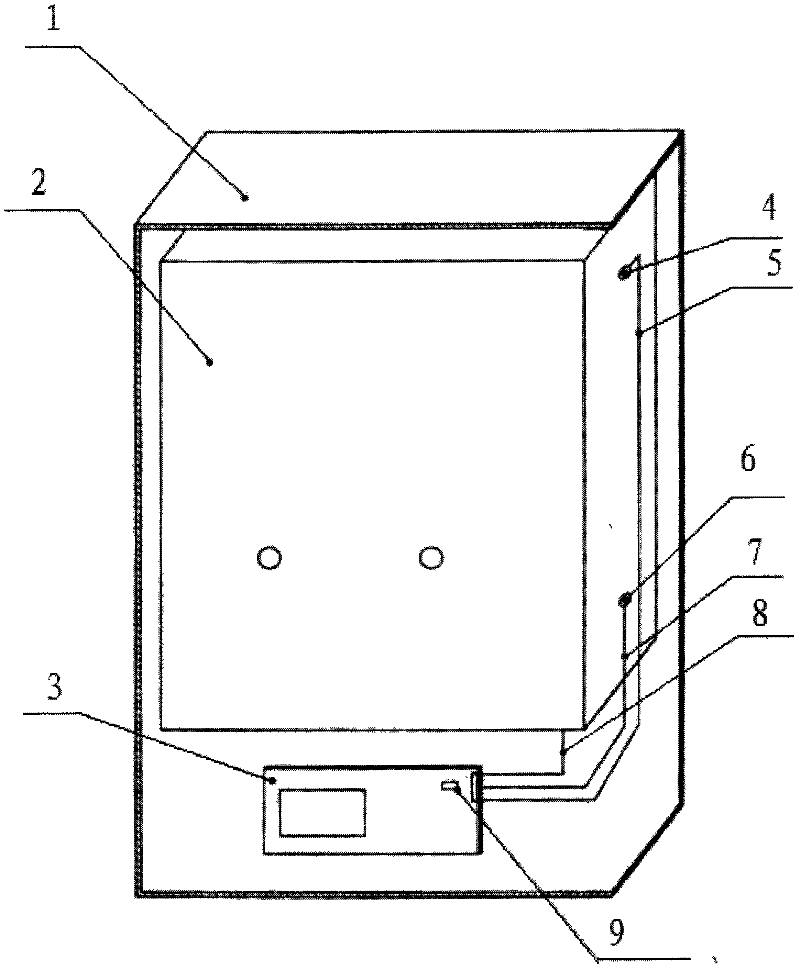

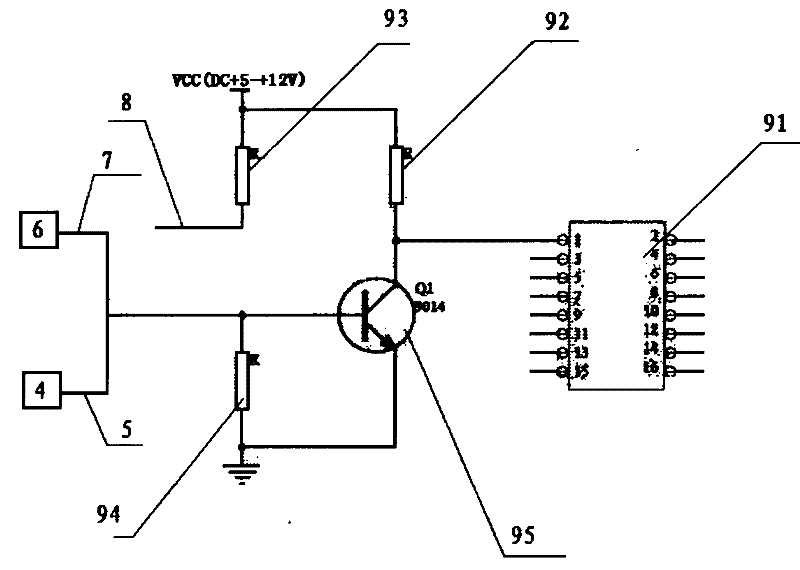

[0027] Combine below figure 1 and figure 2 , the present invention is further described:

[0028] Such as figure 1 As shown, the base of the triode transistor 95 is connected to the water level electrode, the emitter is grounded, the sensitivity resistor 94 is connected between the emitter and the base, the collector is connected to the microcomputer intelligent controller 91, and the collector is connected to the circuit power supply voltage VCC. A pull-up resistor 92 is also connected, and a current limiting resistor 93 is also connected between the circuit power supply voltage VCC and the electrode common terminal.

[0029] The turn-on voltage of the triode transistor 95 is 0.7V; under the effect of the resistance of pure water itself and the sensitivity resistor 94, when the voltage of the water level electrode reaches 0.7V, the triode transistor 95 is just turned on, and the microcomputer intelligent controller 91 When the voltage of pin 1 changes from 3.3V to 0V, its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com