Automobile heat radiator with water chamber rectification baffle plate

A technology for automobile radiators and radiators, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., which can solve the problem of uneven flow of coolant, aggravate the uneven heat dissipation effect of radiators, and fail to meet the requirements of heat dissipation. Functional requirements etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

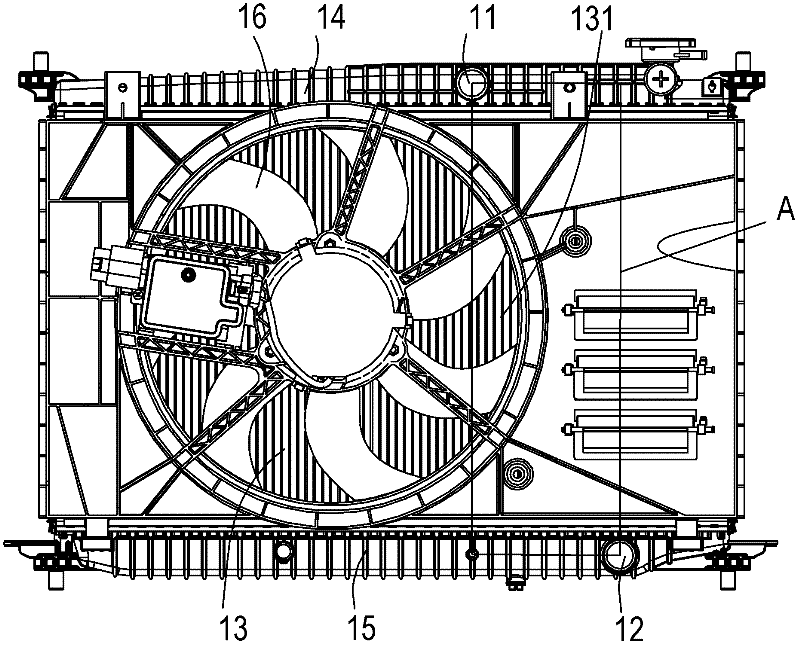

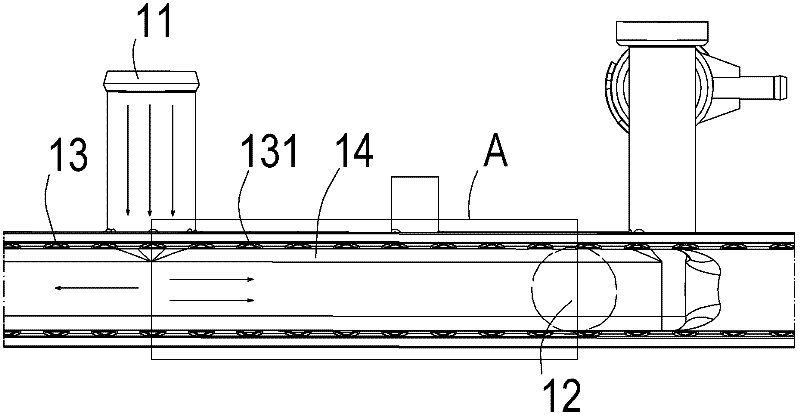

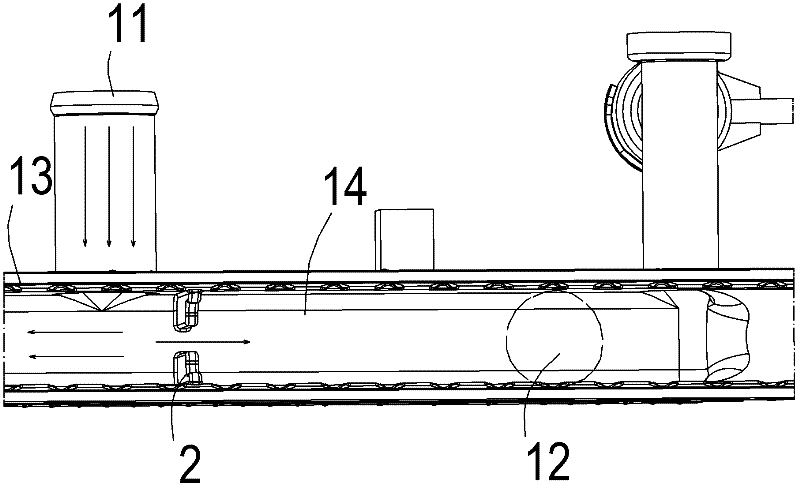

[0022] Such as image 3 As shown, the automobile radiator with water chamber rectifying baffle of the present invention, its overall structure is basically the same as the existing automobile radiator, mainly including the water inlet water chamber 14 with the cooling liquid inlet 11, the water inlet chamber 14 with the cooling liquid outlet 12 Outlet water chamber ( image 3 not shown), and the cooling pipeline 13 that runs through the water inlet water chamber 14 and the water outlet water chamber. The cooling liquid enters from the cooling liquid inlet 11 of the water inlet water chamber 14 of the radiator, flows along the cooling pipeline 13 , finally flows into the water outlet water chamber, and flows out through the cooling liquid outlet 12 .

[0023] Wherein, due to factors such as structural limitations of the whole vehicle, the coolant inlet 11 and the coolant outlet 12 are arranged on the same side of the radiator.

[0024] The special feature of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com