Device and method for desalinizing alkaline water and seawater as well as concentrating and recovering mineral salts

A brackish water and mineral salt technology, applied in seawater treatment, separation methods, ion-exchange water/sewage treatment, etc., can solve the problem that the amount of treated water cannot be infinitely enlarged, so as to improve resource utilization, improve current efficiency, and reduce resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

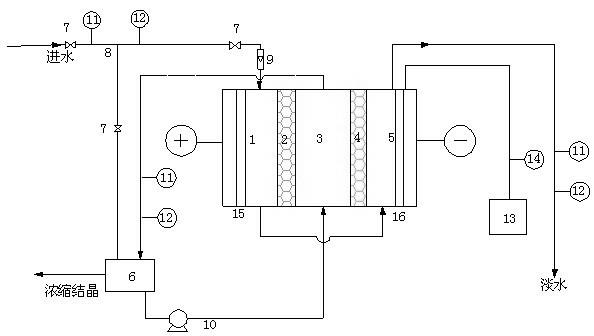

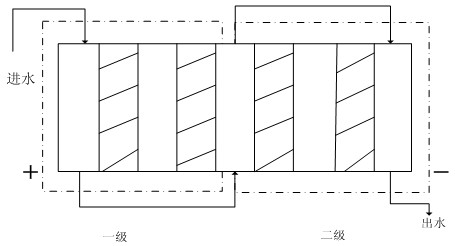

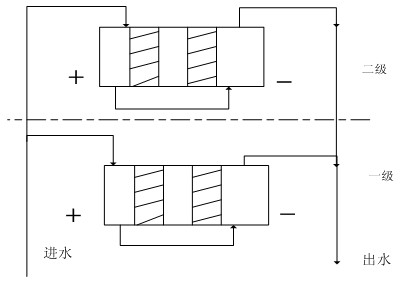

[0030] use figure 1 Shown is a device for desalination of brackish water and seawater, concentration and recovery of mineral salt. The anode is a titanium mesh electrode coated with ruthenium, and the cathode is a stainless steel mesh electrode. The anion and cation exchange resins are respectively D201 macroporous strongly basic styrene-based hydrogen-oxygen resin and D001 macroporous styrene-based hydrogen-type resin. The size of the pool is 0.05432m 3 (1.94*0.2*0.14), the thickness of the resin wall is 0.07m. The raw water is 3% salt water. First, the raw water is diverted by the three-way valve, and the main line enters the first fresh water pool, and then flows out through the second fresh water pool. The auxiliary line water enters the concentrated water pool. Before power is applied, the conductivity of the effluent water is close to that of the raw water. Then apply 30V voltage on both sides of the device to conduct electrodeionization treatment on the raw wat...

Embodiment 2

[0032] This device is used in Example 2 to recover minerals in groundwater. Qinghai Glauber's salt is extremely rich in resources. Glauber's salt is a kind of sulfate mineral, which is a crystal formed by processing and refining the sulfate mineral Glauber's salt. The device, water purification process and operation steps of Example 2 are the same as those of Example 1, except that the cation selective permeable wall is built with diatomite, and the anion selective permeable wall is built with quaternary ammonium strong basic anion resin. The sodium sulfate content in the water is 0.5g / L, and a voltage of 30V is applied to both ends of the electrodes of the device to treat the raw water. After 48 hours of stable operation, the water in the concentrated water tank can reach about 50g / L, and then heated to concentrate and crystallize, which can meet the requirements of recovering Glauber's salt.

Embodiment 3

[0034] In embodiment 3, a membraneless electrodeionization hard water softening device is used to soften boiler water; the deionization device, principle, and operation steps in embodiment 3 are the same as in embodiment 1; 30V is applied to both ends of the device electrodes, and it runs stably and continuously for 20 hours; See Table 1 for water desalination and mineral salt recovery information.

[0035] Ca 2+ (mg / L) Mg 2+ (mg / L) flooded 100 50 out of water 0.5-1.0 0.3-0.8 Concentrated water 5000-10000 2500-8000

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com