Synchronous transport model and method thereof

A technology of synchronous transmission and model, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as inability to obtain accurate values, affecting the accuracy of monitoring AGC, etc., to achieve the effect of accurate synchronous transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] This embodiment is the application of the synchronous transmission model in the automatic thickness control method for high-precision strip rolling monitoring.

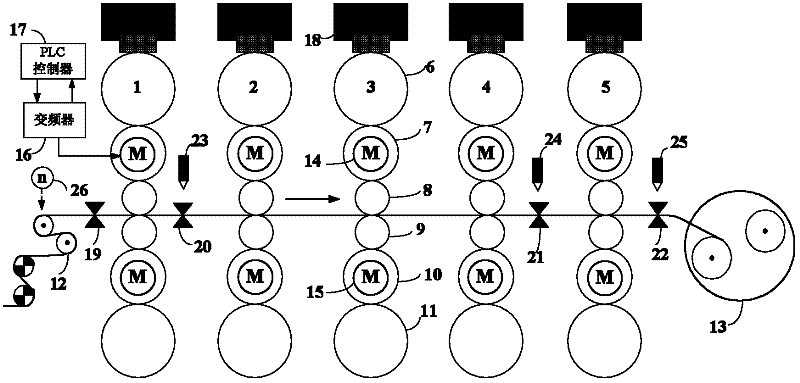

[0038] figure 1 It is a schematic diagram of the five-stand cold tandem rolling mill and the main detection components. The five stands of the five-stand cold tandem rolling mill are all six-high rolling mills. The numbers 1 to 5 on the stands represent stands 1 to 5 respectively, and the rolling direction From left to right. Since the mechanical equipment of each stand is the same, take No. 3 stand as an example to illustrate the equipment composition of the five-stand continuous rolling mill: No. 3 stand is composed of upper support roll 6, upper intermediate roll 7, upper work roll 8, The lower work roll 9, the lower intermediate roll 10, and the lower support roll 11 are composed. In addition, a tension roller 12 is installed at the entrance of the continuous rolling mill, and a coiler 13 is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com