Pallet ordering device

A technology for sorting devices and pallets, which is applied in the directions of transportation and packaging, and unstacking of objects. It can solve the problems of high labor intensity for workers, difficulty in removing pallets, flipping and sorting and stacking, and low labor efficiency. It achieves simple structure, The effect of high labor efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

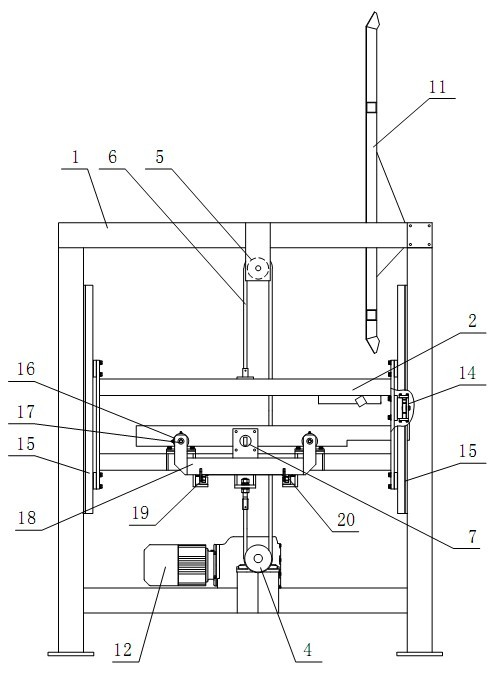

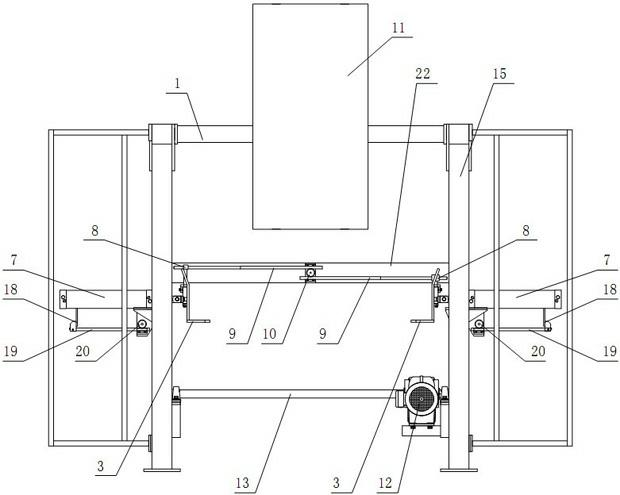

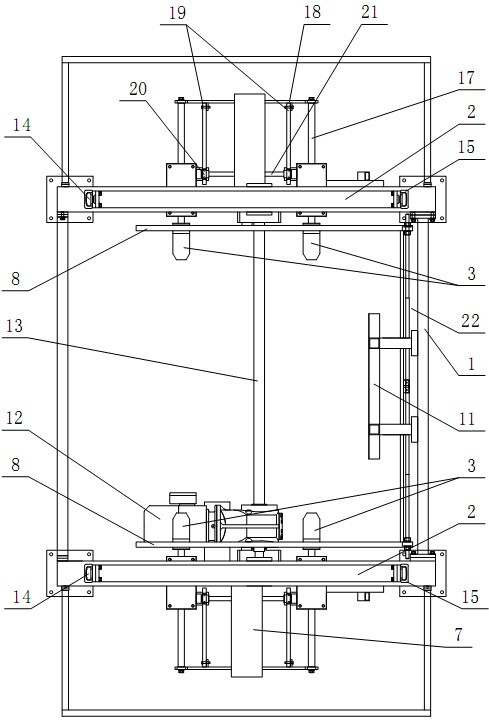

[0016] Such as figure 1 , figure 2 with image 3 The pallet finishing device shown, for the convenience of description, with image 3 The left and right directions in are the front and back positions of the rack 1, that is, the longitudinal direction of the rack 1, image 3 The up and down directions in the frame are the left and right positions of the frame 1, that is, the horizontal direction of the frame 1. The tray finishing device includes the frame 1. The upper part of the frame 1 is fixed with an upwardly extending tray guard 11, and the tray guard 11 is mounted on the machine. The rear side of the frame 1 and its top are higher than the frame 1, and the left and right sides of the frame 1 are respectively slidingly connected with two opposite lifting frames 2, and the vertical guide rail 15 is fixed on the frame 1, and the lifting frame 2 Pulleys 14 sliding along the guide rails 15 are respectively installed at the two ends of the frame 1, and a lifting drive devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com