Method for manufacturing steel plate for can-making

A manufacturing method and steel plate technology, which is applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of inability to obtain TS600MPa strength, deterioration of plate thickness uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

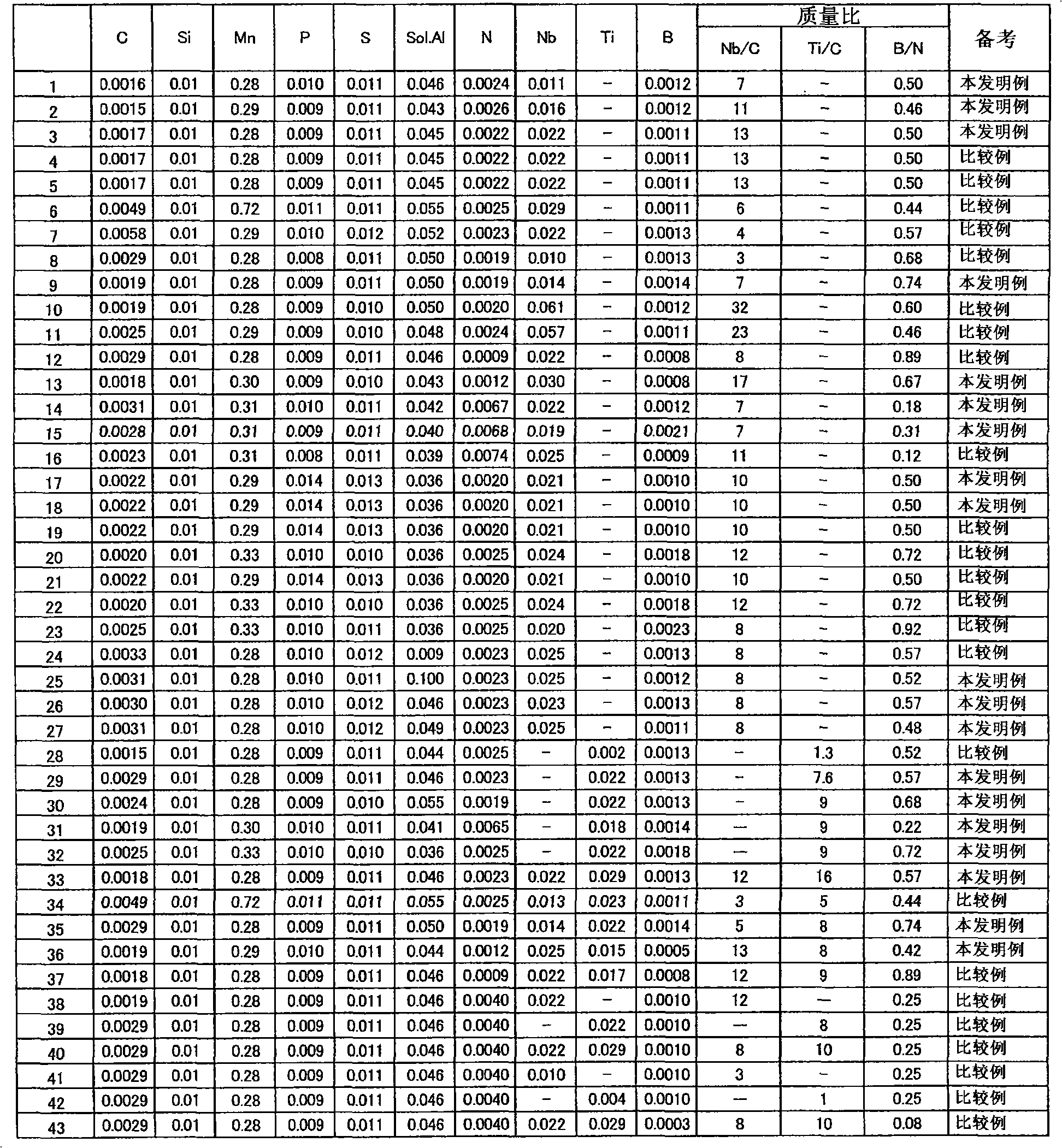

[0066] Examples are described below.

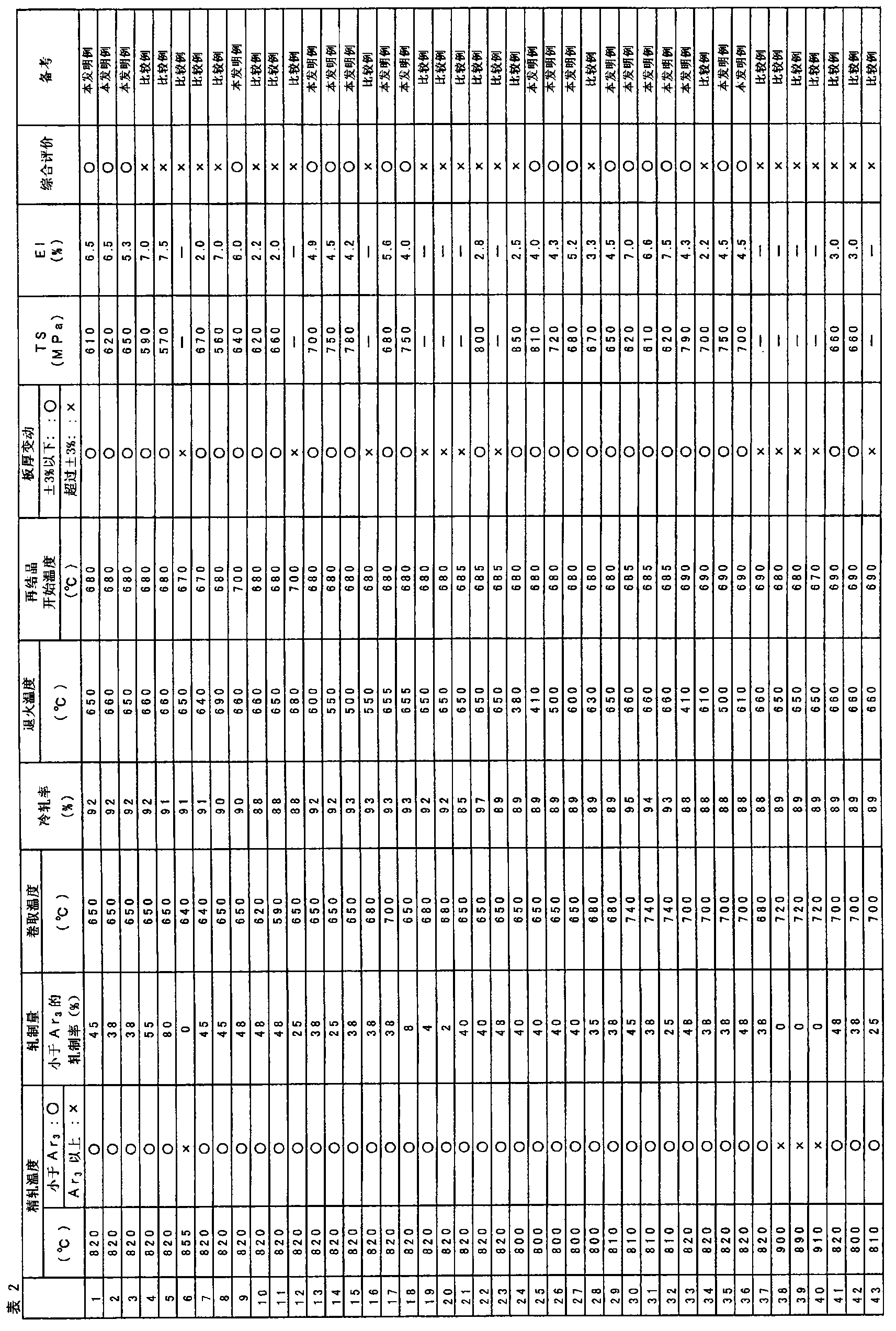

[0067] Various steels containing the components shown in Table 1 were smelted to make slabs with a thickness of 250 mm, heated at a heating temperature of 1100 to 1250 ° C, and rough rolled into thick bars with a thickness of 35 mm. The indicated hot rolling conditions, that is, the finish rolling temperature, are less than Ar 3 Hot rolling was performed at the rolling amount at the transformation point (the ratio of the finishing rolling to the total rolling amount) and the coiling temperature. Next, after pickling, cold rolling was performed at the rolling ratio shown in Table 2, and annealing was performed at the annealing temperature for a soaking time of 10 s to 45 s.

[0068] Table 1

[0069] (quality%)

[0070]

[0071] With regard to the steel sheets obtained as described above, first, variations in sheet thickness were evaluated.

[0072] Sheet thickness fluctuations are measured by the X-ray thickness gauge installed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com