High -altitude operation activity arm frame support structure

A kind of high-altitude operation and support structure technology, applied in the direction of lifting device, etc., can solve the problem of increased storage length, etc., and achieve the effect of convenient control, reliable performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

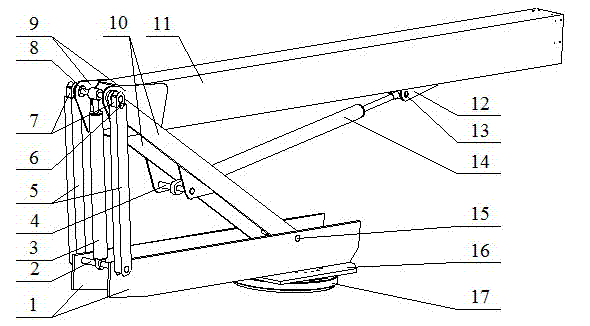

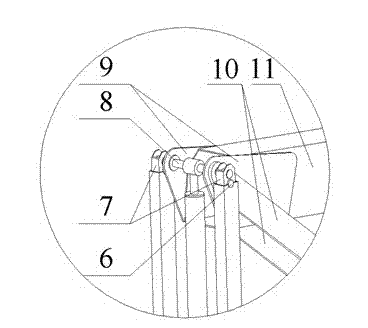

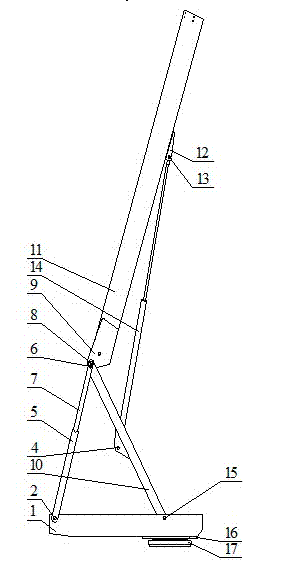

[0016] The support structure of the active arm frame for aerial work of the present invention is as follows: figure 1 As shown, it mainly includes a main frame 1, an outer balance bar 5, an inner balance bar 7, an auxiliary beam 10 and a telescopic arm 11. The main frame 1 is welded on the slewing support plate 16. During the working process, the main frame 1 and the slewing support plate 16 rotate together with the slewing support 17 on the chassis of the aerial work vehicle (or platform). The lower end of the outer balance bar 5 is hinged with the main frame 1 through the pin shaft 2 to form a rotatable connection. The inside of the outer balance bar 5 is covered with an inner balance bar 7 to form a telescopic structure. The outer balance bar 5 and the inner balance bar 7 are hollow rods with a rectangular cross section. The sliding block of the guide function (marked at the end of the figure). When the inner balance bar 7 and the outer balance bar 5 are in the stowed sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com