Magnetorheological vibration reduction system based on shearing work mode for cylindrical turning vibrations

A technology of external turning and shearing work, applied in turning equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of turning chatter in machining volume, reduce turning noise, suppress chattering in external turning, extend The effect of tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

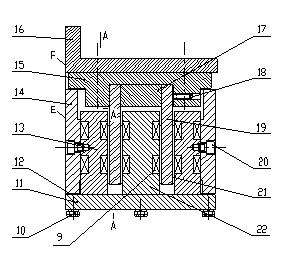

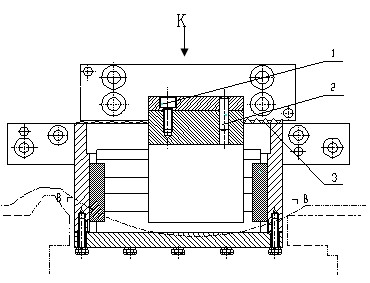

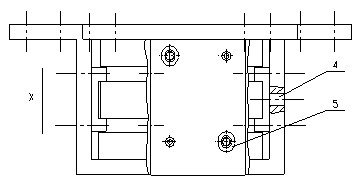

[0019] Figure 1 to Figure 4 As shown, the present invention is composed of two major parts, a sliding pole assembly and a fixed pole assembly, wherein the sliding pole assembly mainly includes parts such as an upper limit slot 15, a connecting plate 16, an upper separator 17, and an upper magnetic pole 19, and the entire sliding pole assembly passes through The connecting plate 16 is fixed on the lathe horizontal carriage with screws; and the fixed magnetic pole assembly mainly includes parts such as the lower limit groove 7, the lower magnetic poles 13 on two sides, the lower magnetic pole 22 in the middle, the lower bottom plate 11 and the lower box body 14, and it passes through Lower casing 14 is fixed on the saddle side plane with screws. During the vibration process of outer circle turning, the vibration of the turning tool will be transmitted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com