Injector nozzle matching parts for diesel engine

A fuel injector, diesel engine technology, applied in engine components, mechanical equipment, machines/engines, etc., can solve the problems of shortening the fuel injection duration and limiting the fuel injection rate, and achieve the effect of optimizing the structural design and increasing the fuel injection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

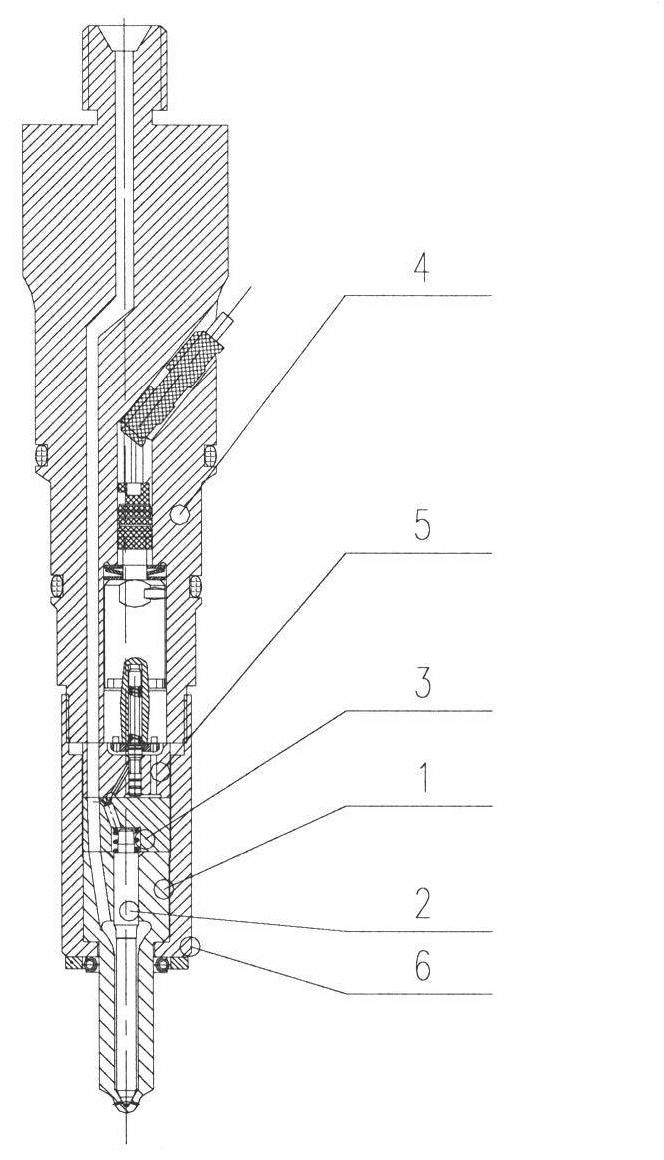

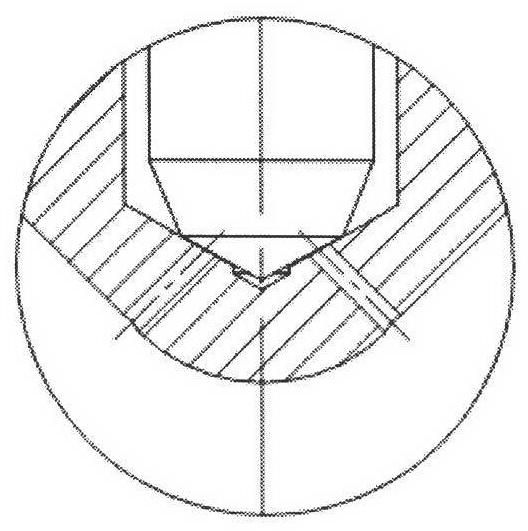

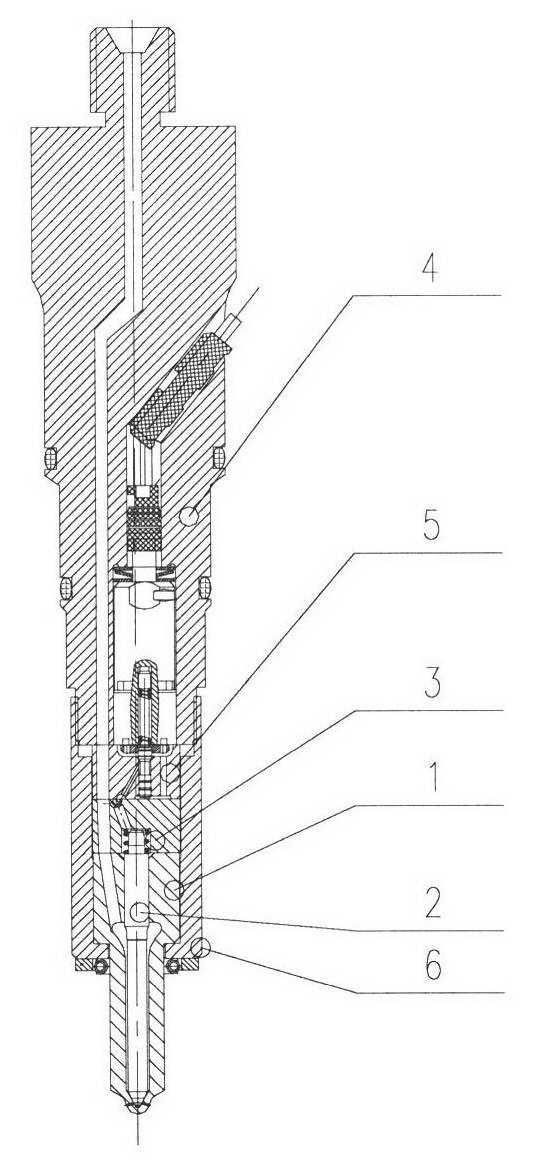

[0009] A fuel injector assembly for a diesel engine, which includes a fuel injector body 1, a fuel injector needle valve 2, a needle valve spring 3, a fuel injector body 4, a fuel injector middle part 5 and a compression nut 6, which The injector body 1 and the injector needle valve 2 form an injector assembly. The injector assembly is arranged below the injector intermediate body 5. The needle valve spring 3 is arranged at the root of the injector needle valve 2. The intermediate body 5 and the fuel injection nozzle assembly are arranged under the fuel injector body 4 through the compression nut 6, and the sealing cone angle formed by the fuel injection nozzle body 1 and the fuel injection nozzle needle valve 2 is 120°.

[0010] Such as figure 1 As shown, in a general diesel engine fuel supply system, the fuel passes through the internal oil passages of the pump, pipeline, and fuel injector, and finally must be injected into the cylinder through the injection hole of the fuel inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com