Chip LED (light emitting diode) display screen and manufacturing method thereof

A technology for an LED display screen and a manufacturing method, applied in the directions of identification devices, instruments, lighting and heating equipment, etc., can solve the problems of poor anti-static ability, poor consistency, and low protection performance, and achieve stable performance and good display effect. , the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

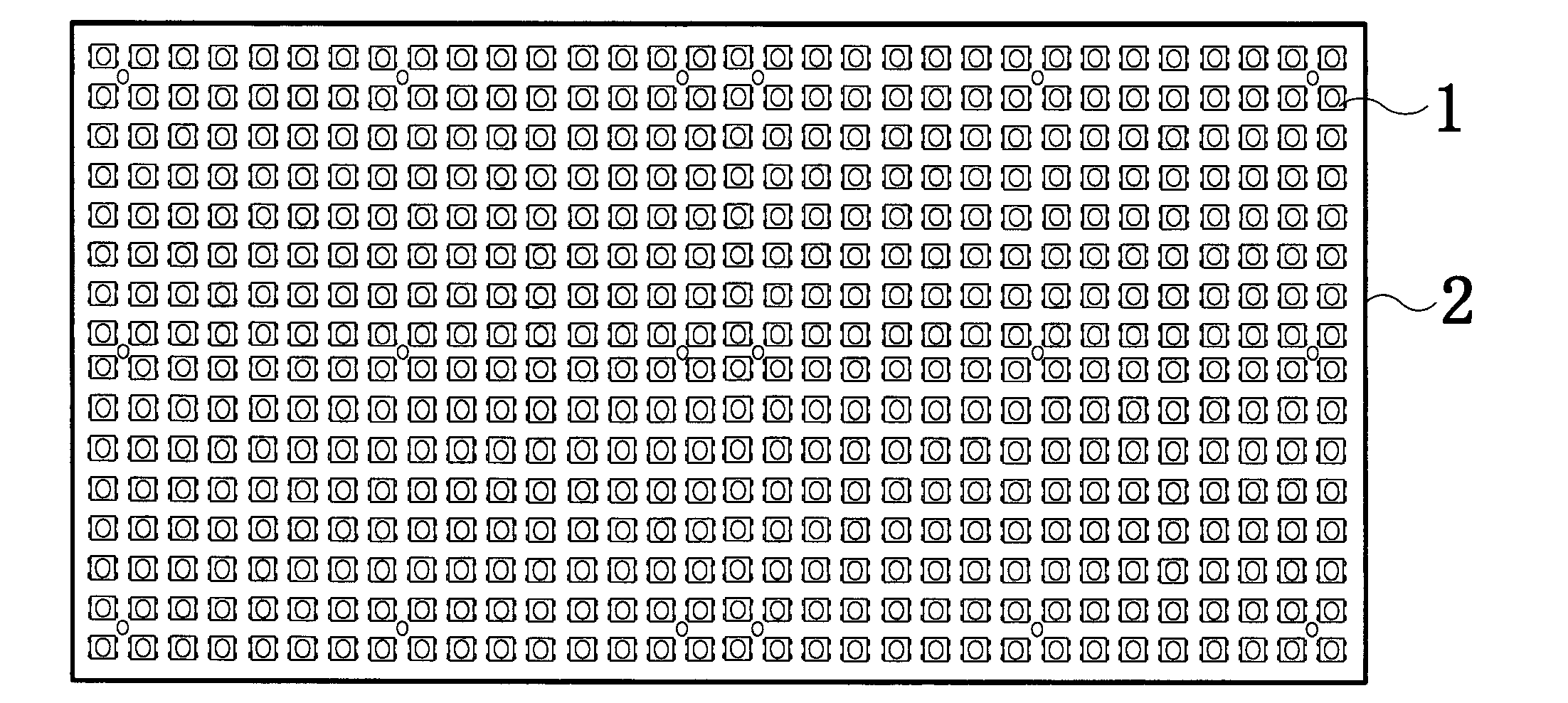

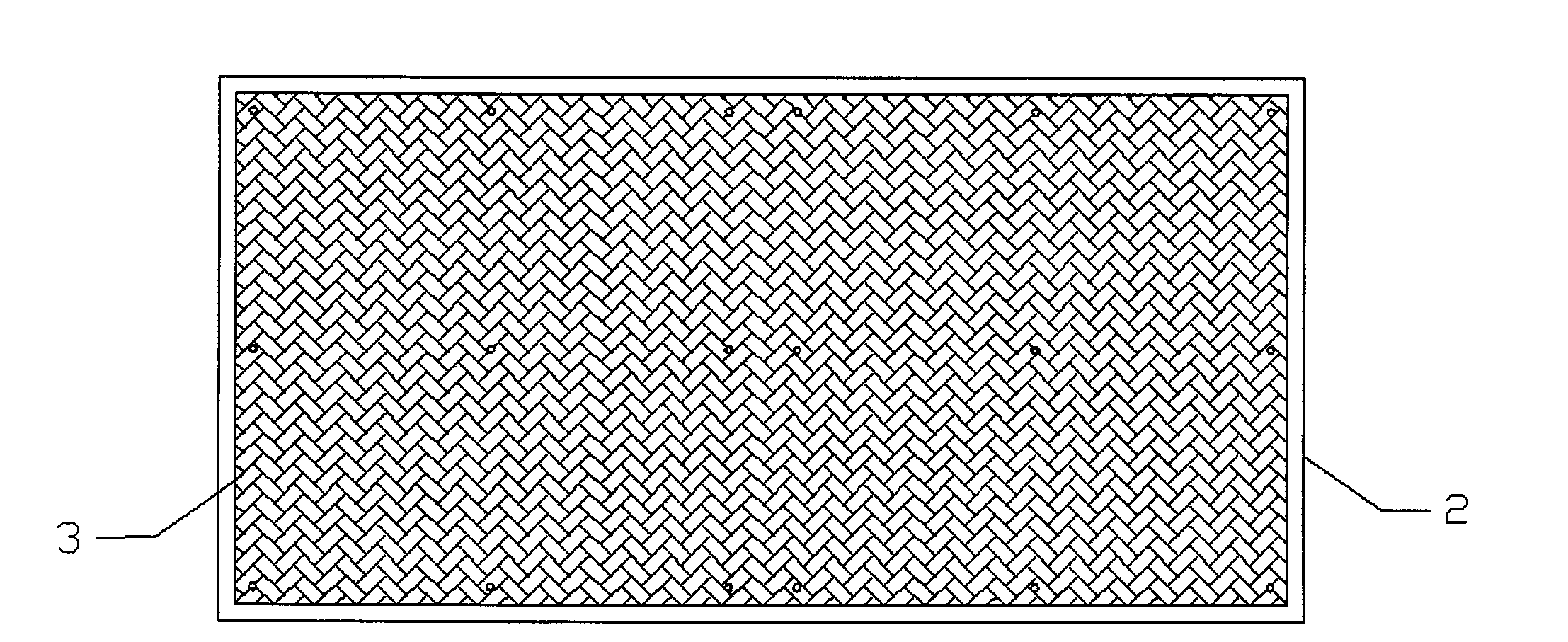

[0039] Step 1. The mounted high-brightness SMD LED lamp 1 is connected to the circuit board 2 by welding, and the reverse side of the circuit board 2 to which the SMD LED lamp 1 is welded is processed with an anti-adhesive protective film 3, see figure 1 and figure 2 ;

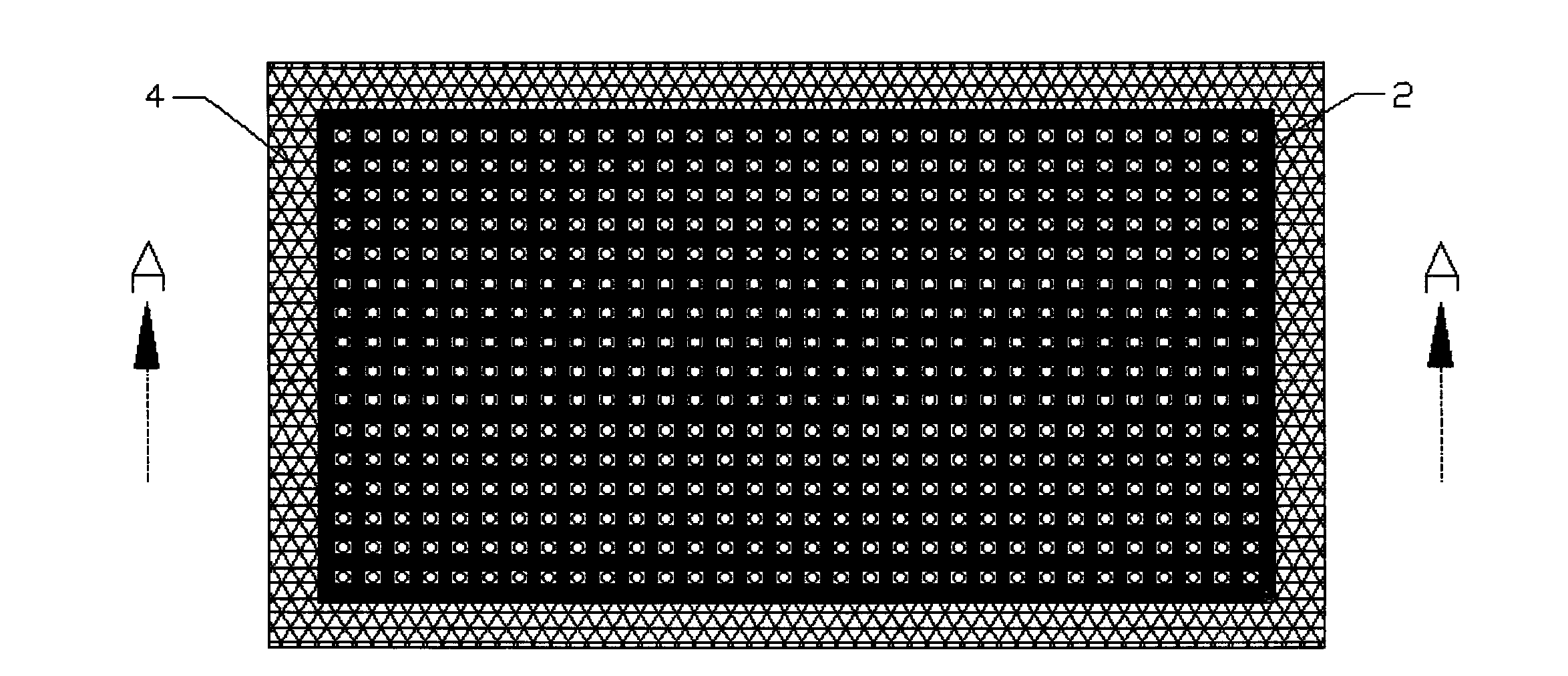

[0040] Step 2. The circuit board 2 and the plastic injection mold 4 after being treated with the anti-adhesive protective film 3 are locked by screws 5, and a black waterproof colloid 7 with a hardness of 60 Shore D is injected into the plastic injection mold through the plastic injection port 6. The liquid level of the waterproof colloid 7 is equal to the height of the top of the SMD LED lamp. The waterproof colloid 7 contains materials that resist ultraviolet rays, acid rain and reduce reflection. After the waterproof colloid 7 is cured, it is demolded and the anti-adhesive protective film 3 is removed. , see image 3 and Figure 4 ;

[0041] Step 3. The excess part of the glue on the edge of the circui...

Embodiment 2

[0045] Step 1. The mounted high-brightness SMD LED lamp 1 is connected to the circuit board 2 by welding, and the reverse side of the circuit board 2 to which the SMD LED lamp 1 is welded is processed with an anti-adhesive protective film 3, see figure 1 and figure 2 ;

[0046] Step 2. The circuit board 2 and the plastic injection mold 4 after being treated by sticking the anti-adhesive protective film 3 are locked by screws 5, and a black waterproof colloid 7 with a hardness of 80 Shore D is injected into the plastic injection mold through the plastic injection port 6. The liquid level of the waterproof colloid 7 is equal to the height of the top of the SMD LED lamp. The waterproof colloid 7 contains materials that resist ultraviolet rays, acid rain and reduce reflection. After the waterproof colloid 7 is cured, it is demolded and the anti-adhesive protective film 3 is removed. , see image 3 and Figure 4 ;

[0047] Step 3. The excess part of the glue on the edge of the...

Embodiment 3

[0051] Step 1. The mounted high-brightness SMD LED lamp 1 is connected to the circuit board 2 by welding, and the reverse side of the circuit board 2 to which the SMD LED lamp 1 is welded is processed with an anti-adhesive protective film 3, see figure 1 and figure 2 ;

[0052] Step 2. The circuit board 2 and the plastic injection mold 4 after being treated with the anti-adhesive protective film 3 are tightened and assembled through the screws 5, and the black waterproof colloid 7 with a hardness of 65 Shore D is injected into the plastic injection mold through the plastic injection port 6. The liquid level of the waterproof colloid 7 is level with the top of the SMD LED lamp. The waterproof colloid completely covers the circuit board. Due to the wall-climbing effect of the liquid, the waterproof colloid also covers the metal conductive pins of the SMD LED lamp 1. At the same time, the LED and the A groove area is formed between the LEDs;

[0053] Step 3. The excess part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com