Stator for efficient and super-efficient three-phase asynchronous motors

A three-phase asynchronous, ultra-high-efficiency technology, applied in the field of electric motors, can solve the problem of low mechanical strength of the stator core, low precision of the verticality of the stator core, stray loss of the motor, large eddy current loss of the core loss, insufficient output efficiency and production efficiency of the motor, etc. problem, to achieve the effect of improving precision, increasing lamination coefficient, and improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

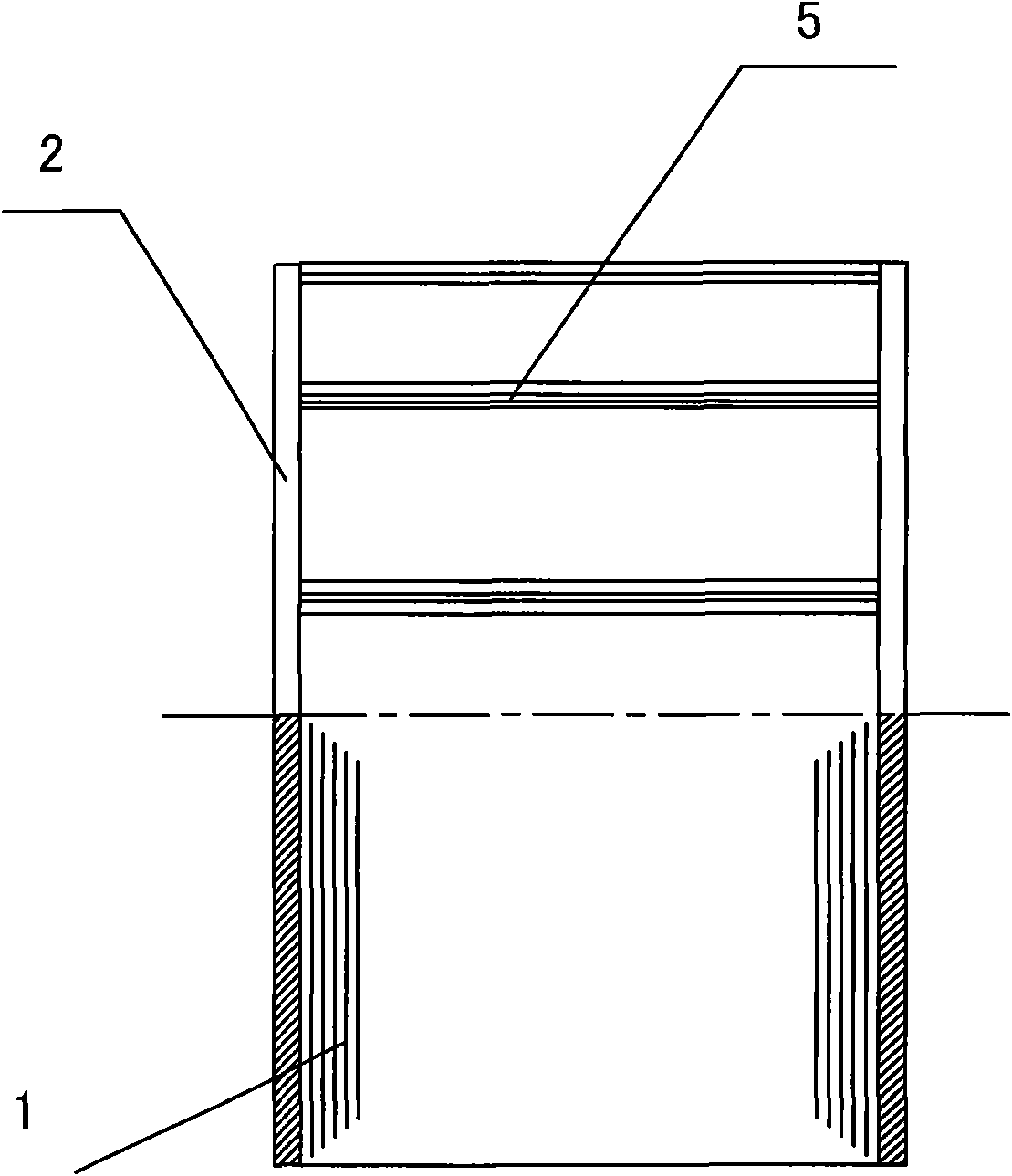

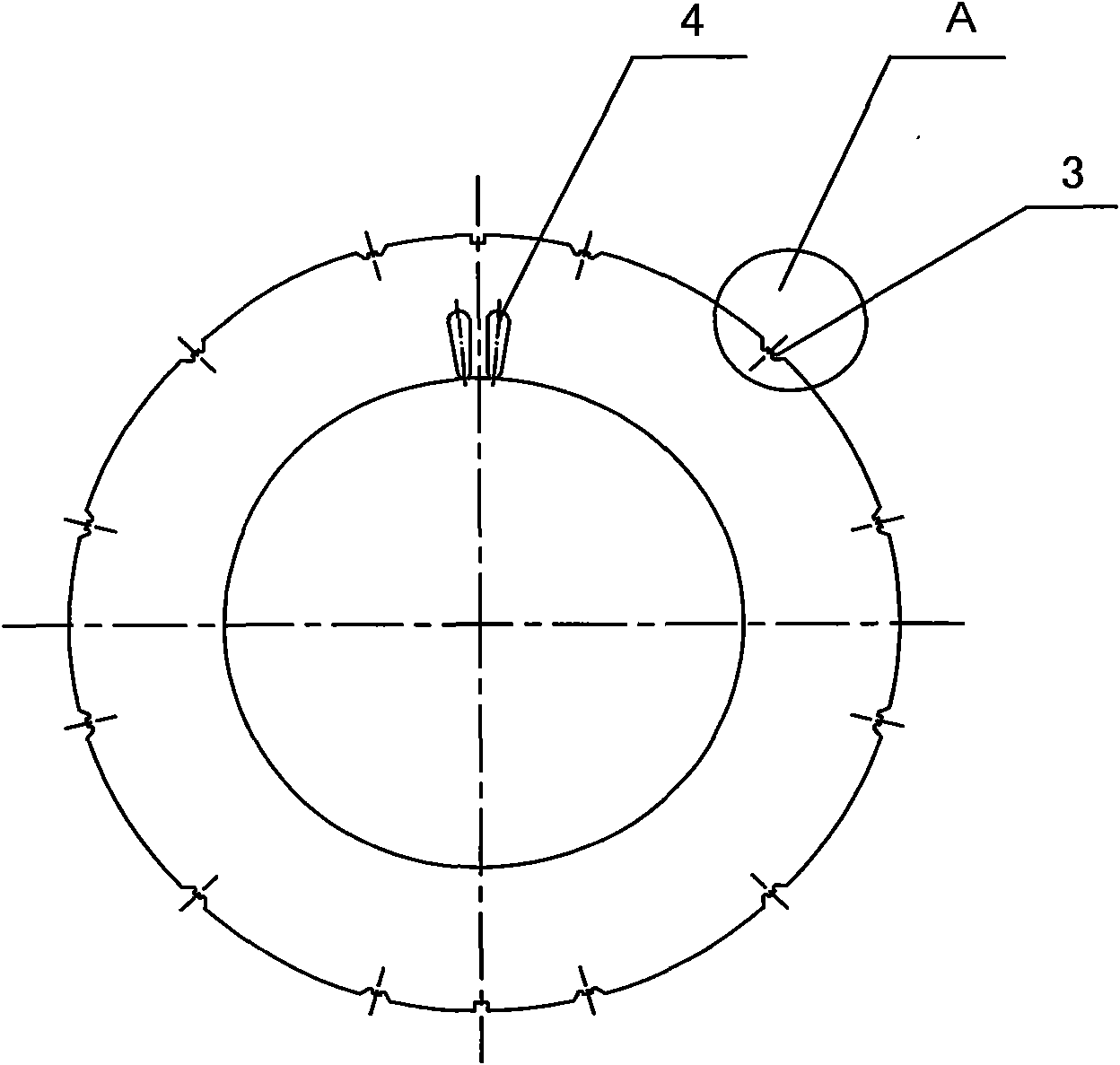

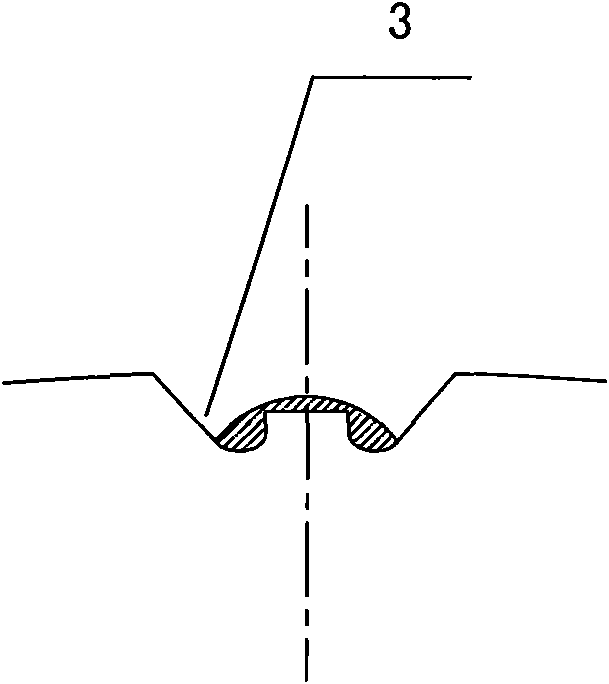

[0015] In order to better understand the technical solution of the present invention, the following specific examples in conjunction with the accompanying drawings figure 1 , figure 2 , image 3 Give a detailed explanation.

[0016] The present invention is a stator for a high-efficiency and ultra-high-efficiency three-phase asynchronous motor, which includes a stator core piece 1 and two pressure pieces 2 located at the ends of several stator core pieces, on the outer circumference of the stator core pieces 1 and pressure pieces 2 There are several "W"-shaped notches 3 at intervals, and the stator formed by stacking a number of stator core pieces 1 and two pressure pieces 2 has several shafts formed by stacking "W"-shaped notches 3 on the outer circumference. To the "W" shaped welding groove 5.

[0017] Several stator core pieces 1 and between stator core pieces 1 and pressing pieces 2 are fixed by welding in axial “W”-shaped welding grooves 5 to form a rigid cylinder cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com