Multifunctional internal combustion arc welding generator

An internal combustion arc and generator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as the difficulty of parallel connection of chopper switch tubes and current sharing, achieve excellent dynamic indicators and welding process performance, ensure reliable work, and avoid Effect of excessive transient short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

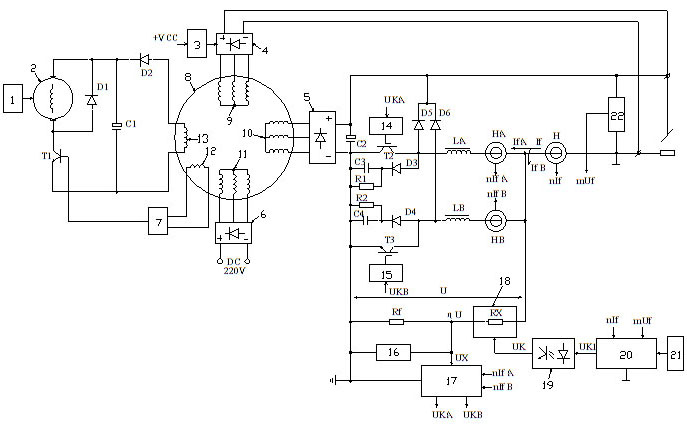

[0036] see figure 1 A multifunctional internal combustion arc welding generator shown includes an internal combustion engine 1, a generator rotor 2, a trigger circuit 3, a thyristor rectifier switch 4, a three-phase bridge rectifier rectifier 5, an auxiliary power rectifier circuit 6, and an excitation current adjustment Circuit 7, generator stator 8, first switching tube T 1 , the second diode D 2 and the first capacitor C 1 , the first diode D 1 and chopper main circuit; it is characterized in that there are external support winding 9, welding winding 10, auxiliary power supply winding 11, feedback winding 12 and excitation winding 13 in the embedding slot of the stator, and the external support winding 9 passes through the thyristor rectifier switch 4 and The output ends of the chopper main circuit are connected in parallel with the same polarity, and the trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com