Heat sealing mechanism of tongue depressor packaging machine

A packaging machine and tongue depressor technology, which is applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of serious spatula pollution, unstable product quality, high labor cost, etc., and avoid excessive heat sealing time. Long, stable quality, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

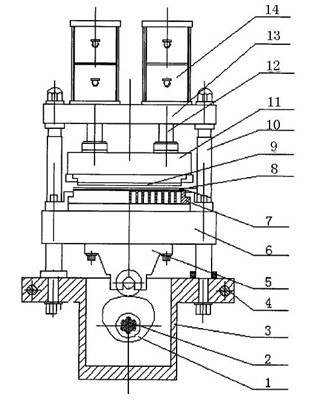

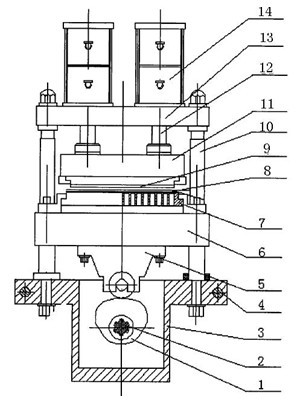

[0011] Such as figure 1 As shown, the cam box 3 is installed on the fuselage through the cam box guide rod 4, the heat-sealing post 12 is installed on the cam box 3, the cylinder bottom plate 15 is installed on the heat-sealing post 12, and the heat-sealing is installed on the cylinder bottom plate 15. After the cylinder 16 is injected with compressed air, the cylinder piston 14 pushes the heat-sealing heating plate 13 and the heat-sealing upper mold (anilox plate) 11 to move down at the bottom dead center, and the heat-sealing heating plate 13 makes the heat-sealing upper mold (anilox plate) ) The temperature of 11 reaches the heat sealing temperature. At the same time, when the spline spindle 2 rotates, the heat-sealing cam 1 in the cam box 3 rotates, so that the roller seat 5 drives the lower mold guide plate 6 and the heat-sealed lower mold 7 installed on the lower mold guide plate 6 to move up and down periodically; the current lower mold guide plate 6 When descending, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com