[0003] However, the existing

wave crest soldering equipment and its

welding technology application have been developed into two forms with

nitrogen and

nitrogen-free, and the technical concepts of these two forms are aimed at reducing tin

slag (

tin oxide, insoluble tin) However, there is still a considerable distance from the ideal goal of Wuxi

Slag. The

current practice of improving air quality is to adopt the confinement method adopted by Gun, the father of Dayu in more than 2,000 BC. Therefore, no more significant effect has been produced so far

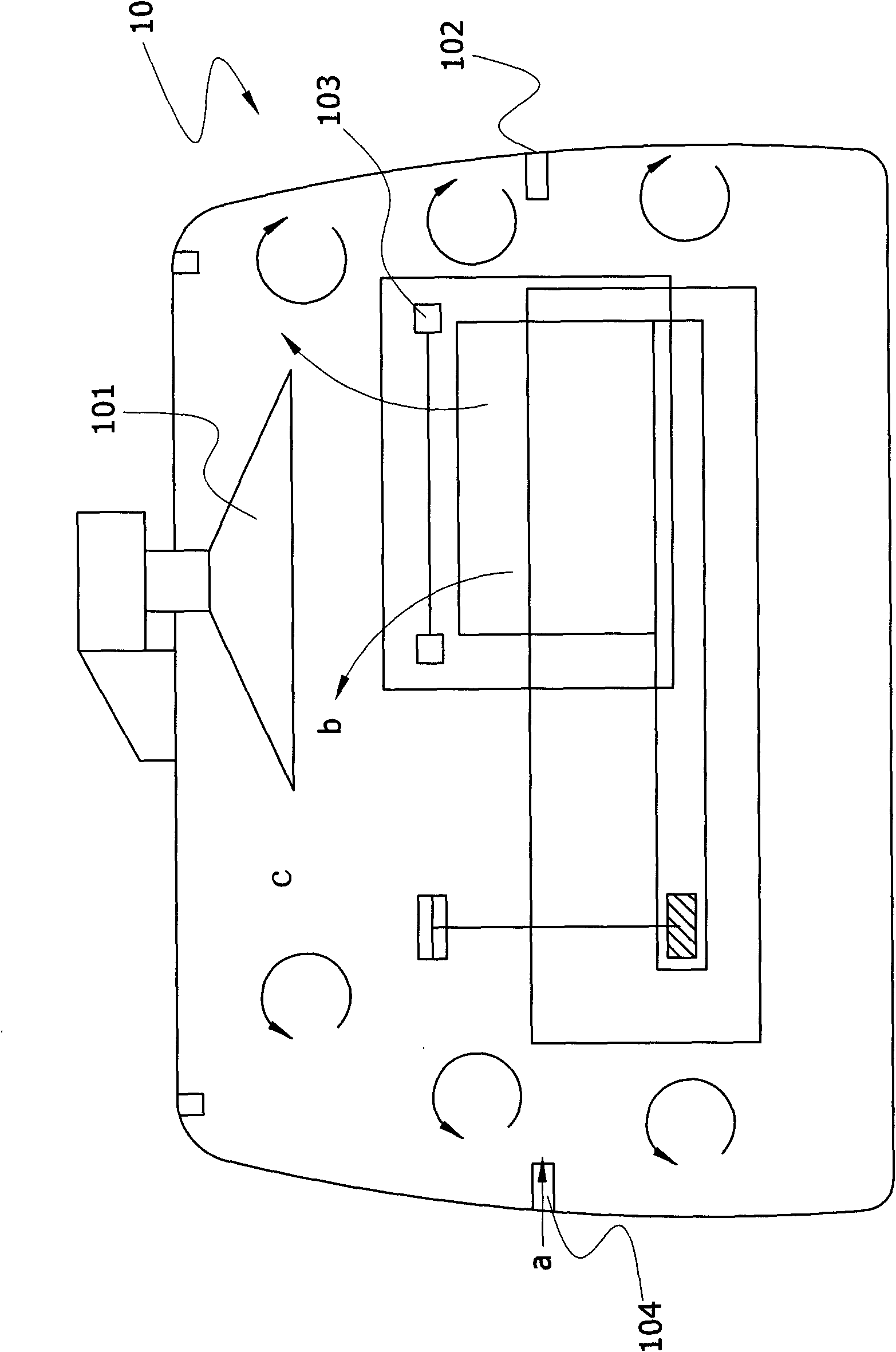

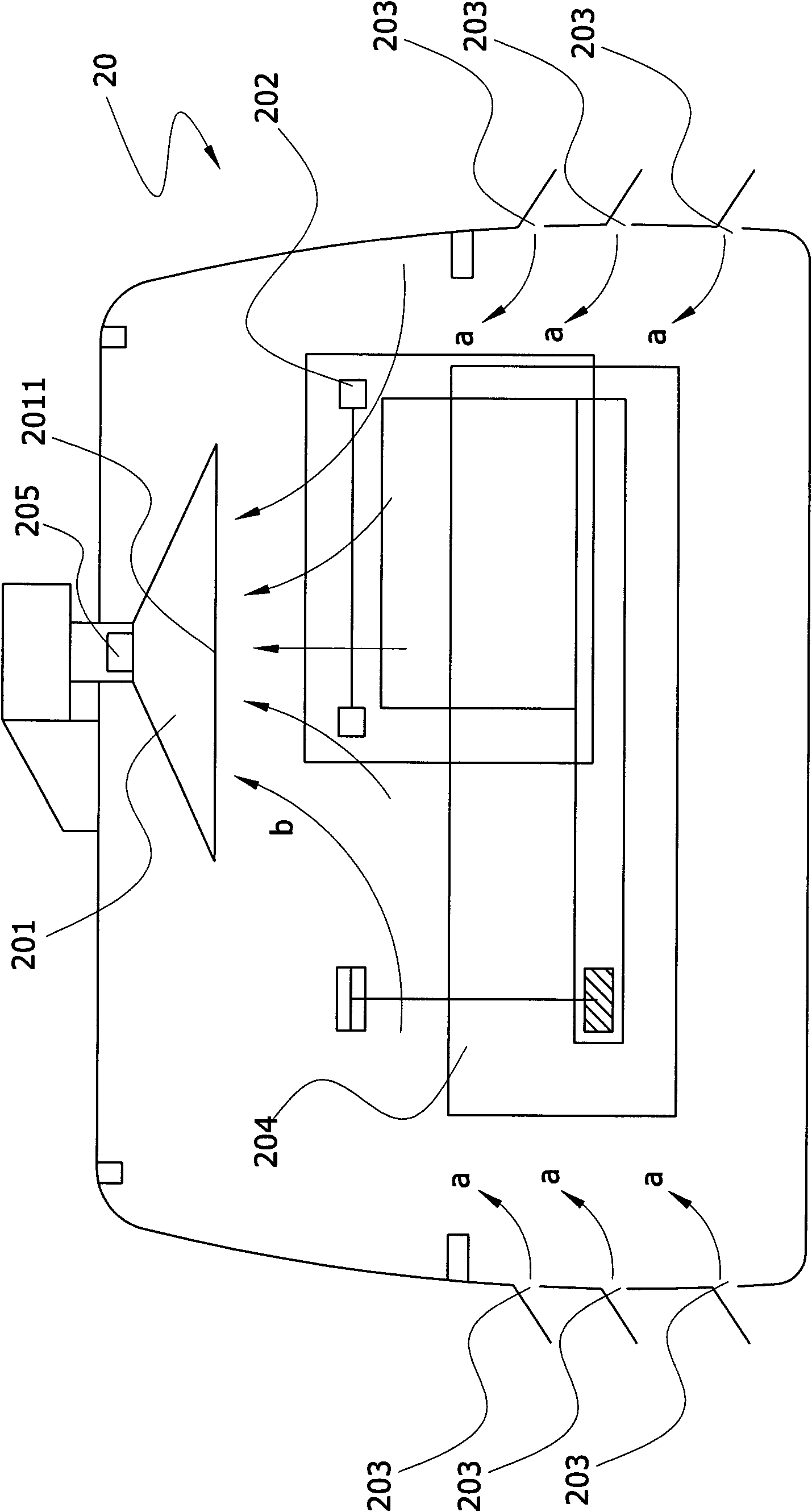

[0004] see figure 1 , shown in the figure is a

schematic diagram of the operation of the intake and exhaust of an existing

wave crest tin dipping

machine. As shown in the figure, the wave crest tin dipping

machine 10, when its air outlet 101 is in normal operation, the casing 102 is completely closed, only There is an inlet and outlet hole 103 for the product clamping chain mechanism, and another inlet and outlet hole 104, whose position is approximately equal to the height of water mist and smog. b The rising direction is at an angle of about 90 degrees, so it will cause water mist and

smoke b to overflow in the casing with turbulent flow (arrow c as shown in the figure), resulting in water mist and smoke b everywhere Attached is a see-through glass for the parts and products; in addition, in order to save the

power consumption of the ventilation, the factory affairs department often adjusts the ventilation speed to be lower and lower, making the ventilation outlet 101 useless, so that flux mist, And the smoke overflows to the outside of the casing. Moreover, the flux mist and smoke adhering to the see-through glass of the

machine must be cleaned weekly with harmful solvents such as IPA, so that the air quality of the existing wave peak soldering machine

production line Poor, personnel often have the reaction of respiratory organ, cardiovascular and blood discomfort, which leads to problems such as

high turnover rate. This is one of the reasons why advanced industrial countries move production lines that endanger health to undeveloped countries in order to protect the health of their people.

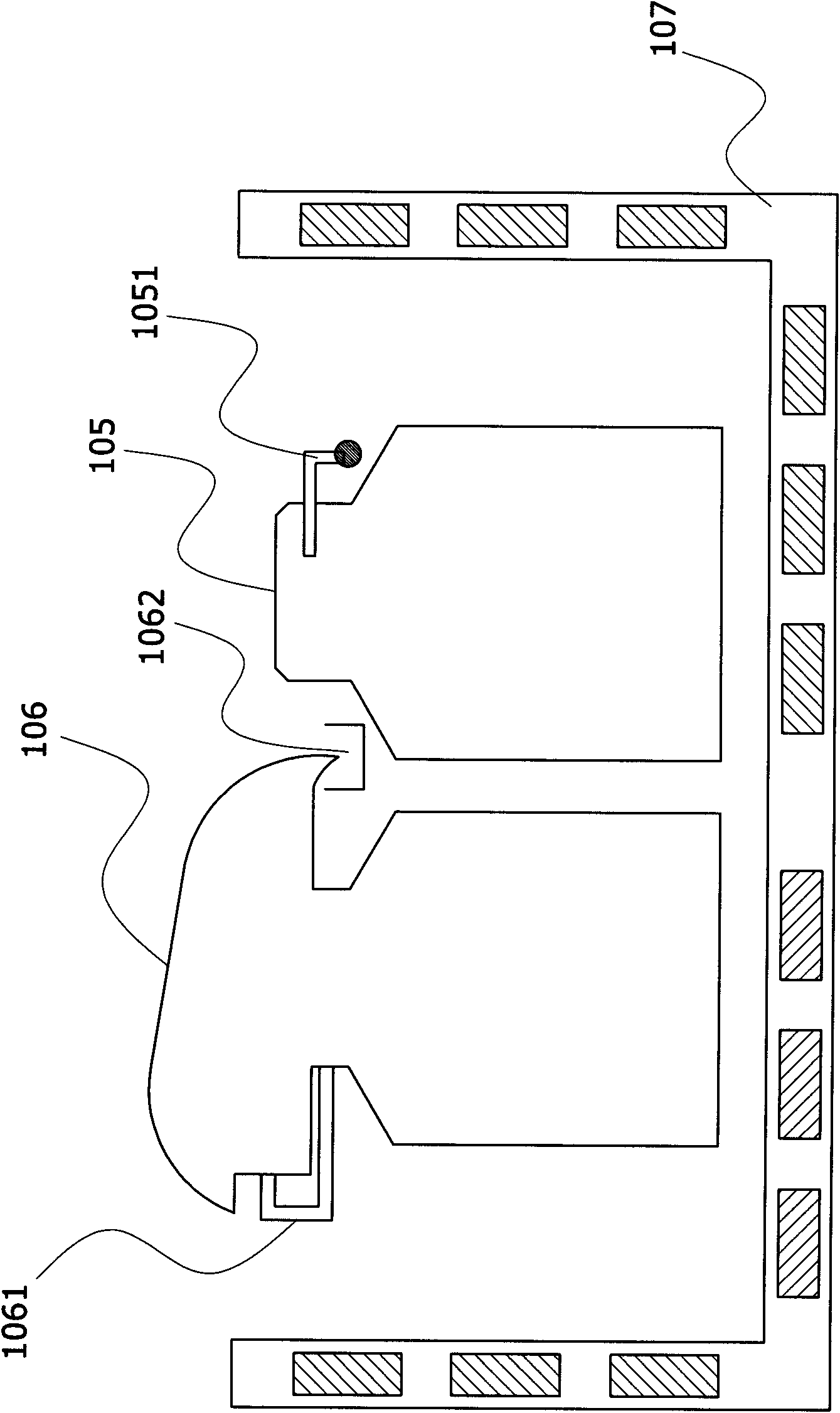

[0005] see figure 2 , the figure shows the arrangement of the inside of the wave tin furnace of an existing wave tin dipping machine and the adjacent mechanisms and accessories. Based on the actual needs of improving tin

slag and soldering quality, some manufacturers have developed related mechanisms that can be matched or accessories, however, these mechanisms or accessories are messily arranged inside and adjacent to the wave peak tin furnace, so that the existing wave peak tin furnace can remove the tin

slag floating on the surface of the molten tin pot, and can purify the synthetic

chemistry of the molten tin pot The

working space for

powder addition is blocked and interfered, which makes the work difficult and time-consuming. For example, a typical case is that the N2 wave peak tin dipping furnace is completely sealed, or as shown in the figure, the existing wave peak tin dipping machine 10. The turbulent wave

nozzle 105 of the tin furnace 107 in the interior swings left and right with the reciprocating mechanism 1051, or various mechanisms are installed around the turbulent wave

nozzle 105 and the advective wave

nozzle 106 mechanism, such as

backflow tin conduit 1061, downward tin Flow conduit 1062, etc., or around the tin liquid pump, install various barrier toner mechanisms, and the unique shape of the product clamping chain mechanism, resulting in a protruding part between the fingertips of the chain mechanism and the bottom wave nozzle opening mechanism , making it difficult and time-consuming to add and remove the synthetic chemical

powder that can purify the molten tin in this area, and sometimes it is even impossible to implement. There is no other way for the above obstacles except to dismantle and replace a more suitable mechanism, but such Temporary repair and replacement measures, as well as the shortcomings of the original design, still cause endless problems. For example, the wave peak tin dipping furnace is a high temperature and dangerous

working environment. The existing wave peak tin dipping furnace must remove the tin slag every 1.5 to 2 hours, and every The working time for removing tin slag on the molten tin surface will be increased due to the interference of the obstacle mechanism;

[0006] In the

business environment of low price and fierce competition, the existing manufacturers of wave crest tin dipping machines all use inferior or worse grade materials, which makes the

chemical resistance of the so-called

titanium alloy far inferior to the material characteristics of SUS304, plus Attaching the heating electric heater to the outer wall of the tin furnace not only wastes

electricity but also further reduces the life of the material and the

chemical resistance[0007] Furthermore, there is another major problem in the existing wave crest tin dipping machine, which is the asynchronous movement of the clamping chain for its products, because the existing wave crest tin dipping machine adopts a synchronous adjustment mechanism for chain tightness, Therefore, when the wear of the two chains is not equal, one of them is still too loose when one of them is tightened synchronously. Trembling phenomenon occurs in the center, resulting in product damage or a

high rate of heavy-duty defects. There is also a unique shape of the product clamping chain mechanism, which causes a protruding part between the fingertips and the bottom wave nozzle opening mechanism, which makes it possible to purify the synthesis of molten tin. The addition and removal of chemical powder in this area is difficult and time-consuming, and sometimes even impossible to perform. Therefore, PCBs often fall off in the machine due to poor clamping, resulting in shutdown and overhaul. The clamping chain mentioned above ,Please refer to Figure 5 , the picture shows the clamping chain mechanism diagram of the existing wave crest tin dipping machine, please refer to

[0008] In addition, the poor ventilation of the existing wave crest tin dipping machine will also cause the accumulation of flux mist in the front section of the preheating zone. If the accumulation is too serious, it may cause a fire, which is harmful to the life safety of the production line personnel and the fire. Significant impacts such as loss of production volume during rebuilding, one of many significant disadvantages that are difficult to manage

Login to View More

Login to View More