Temperature control method of plasma chemical vapor deposition base

A technology of chemical vapor deposition and temperature control method, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of large temperature fluctuation, avoid temperature fluctuation, improve quality and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

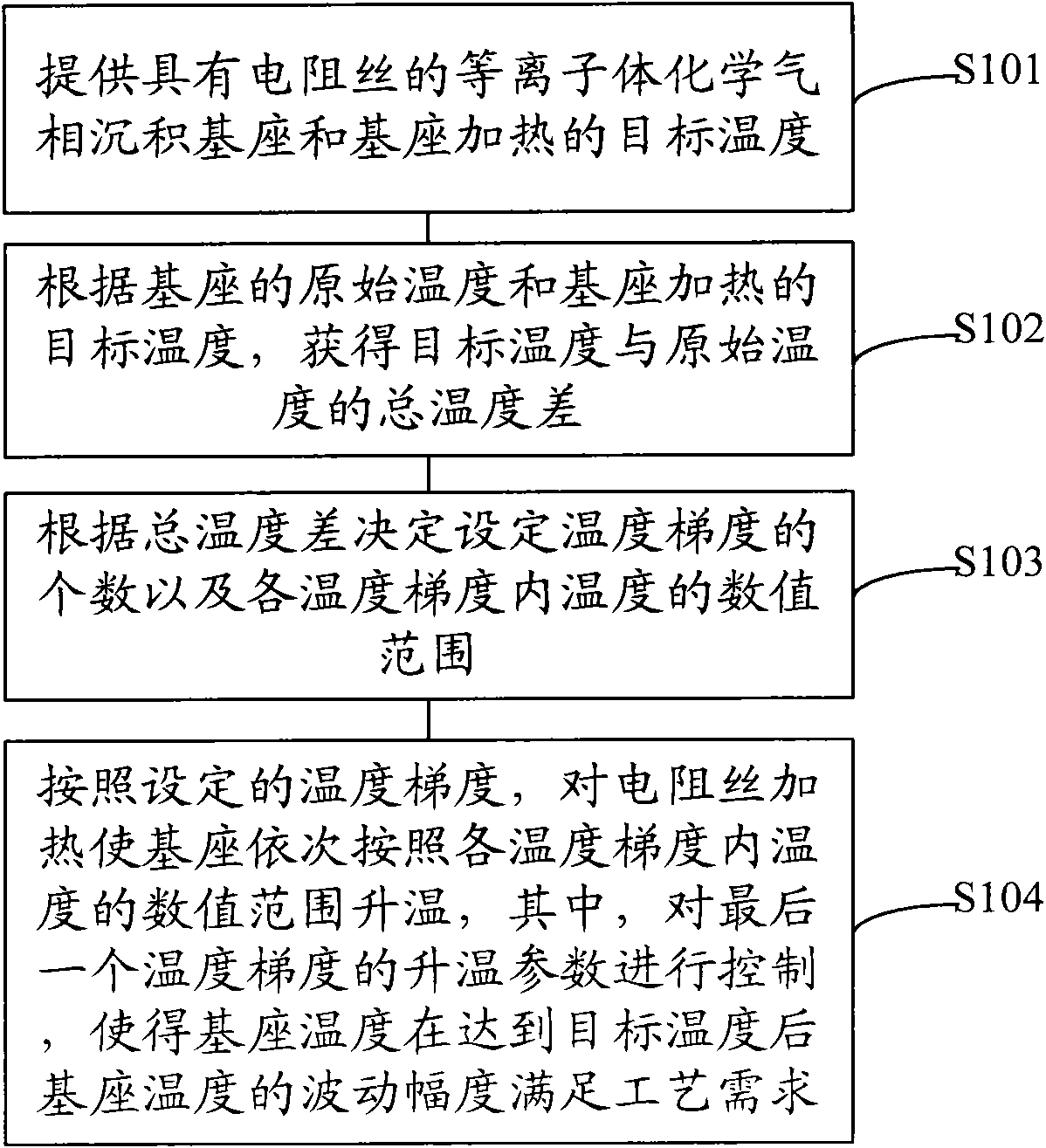

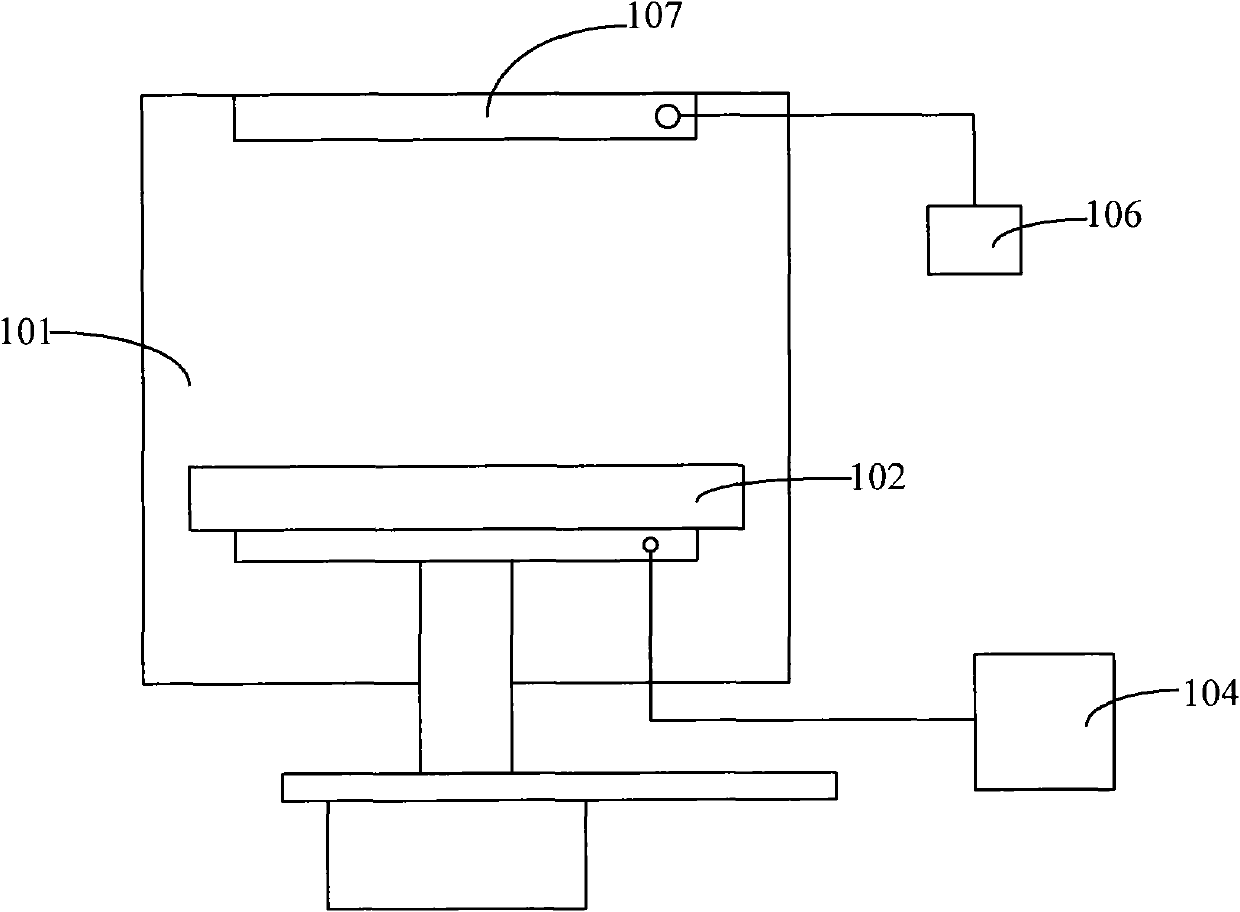

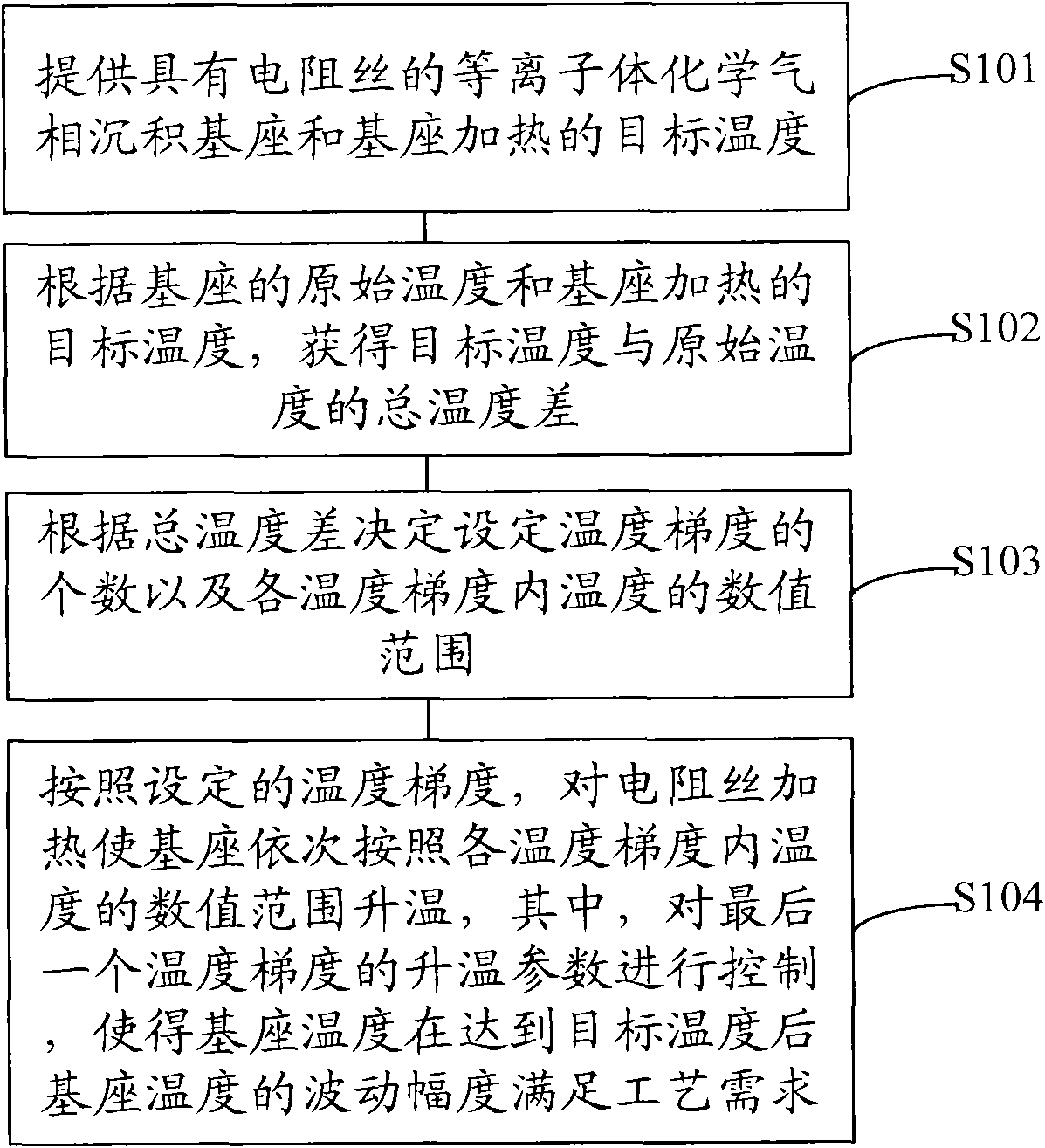

[0016] Please refer to figure 1 , figure 1 It is a schematic diagram of a plasma chemical vapor deposition device, including: a reaction chamber 101, a susceptor 102 at the bottom of the chamber, a temperature control device 104 for controlling the temperature of the susceptor, a gas spray device 107 for distributing gas, and a A plasma generator 106 that generates plasma. The susceptor 102 is used for placing the substrate (not shown) on which the film is to be deposited, and the susceptor has a resistance wire (not shown) for heating therein. The temperature control device 104 is electrically connected to the base 102 for controlling the temperature rise and fall of the base. The gas spraying device 107 is located at the top of the chamber and is opposite to the base 102 .

[0017] The temperature control device 104 of the above-mentioned plasma chemical vapor deposition apparatus is used to directly apply power to the resistance wire to heat the base 102. The base temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com