Lamp lighting device and filament lamp

A filament lamp and filament technology, applied in ohmic resistance heating devices, incandescent lamps, incandescent lamp components, etc., can solve the problems of energy consumption, production cost increase, power loss, etc., and achieve the goal of reducing the number of parts and suppressing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

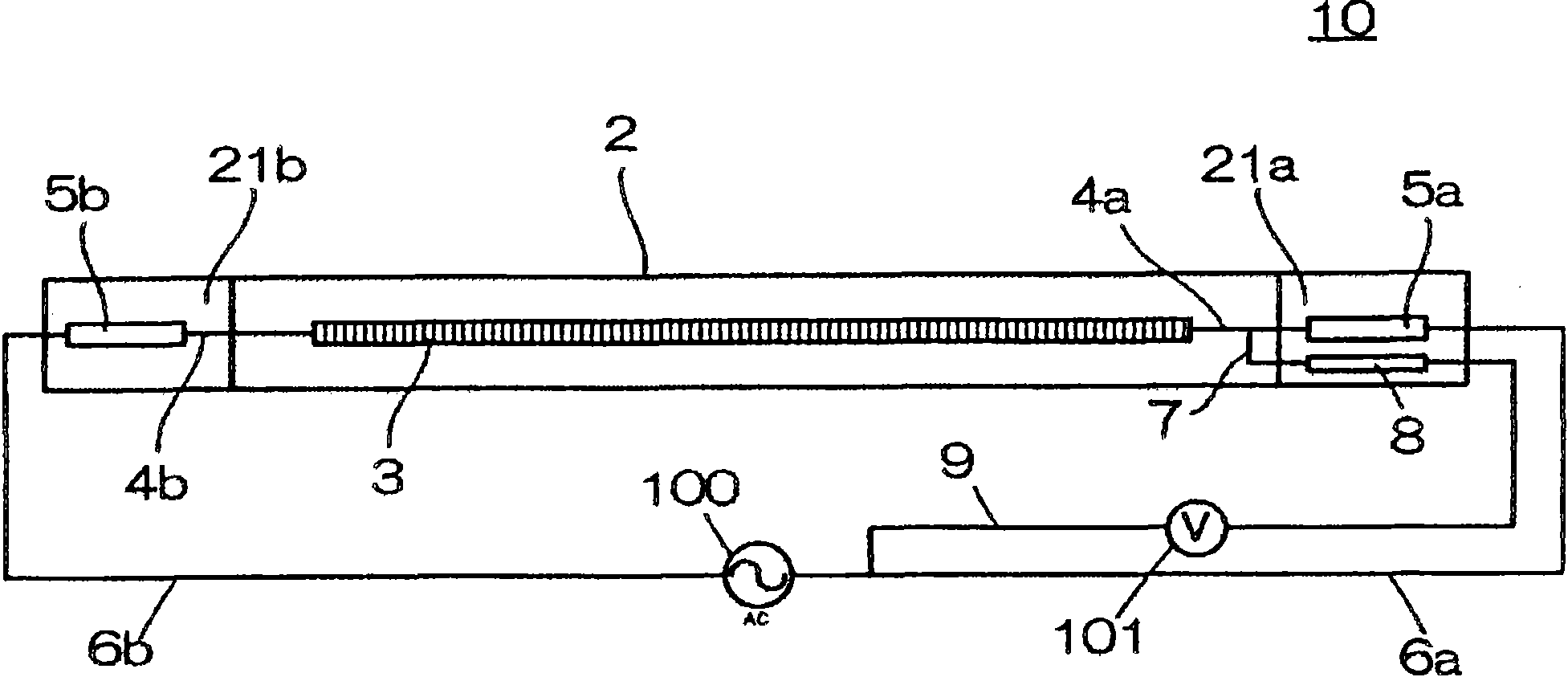

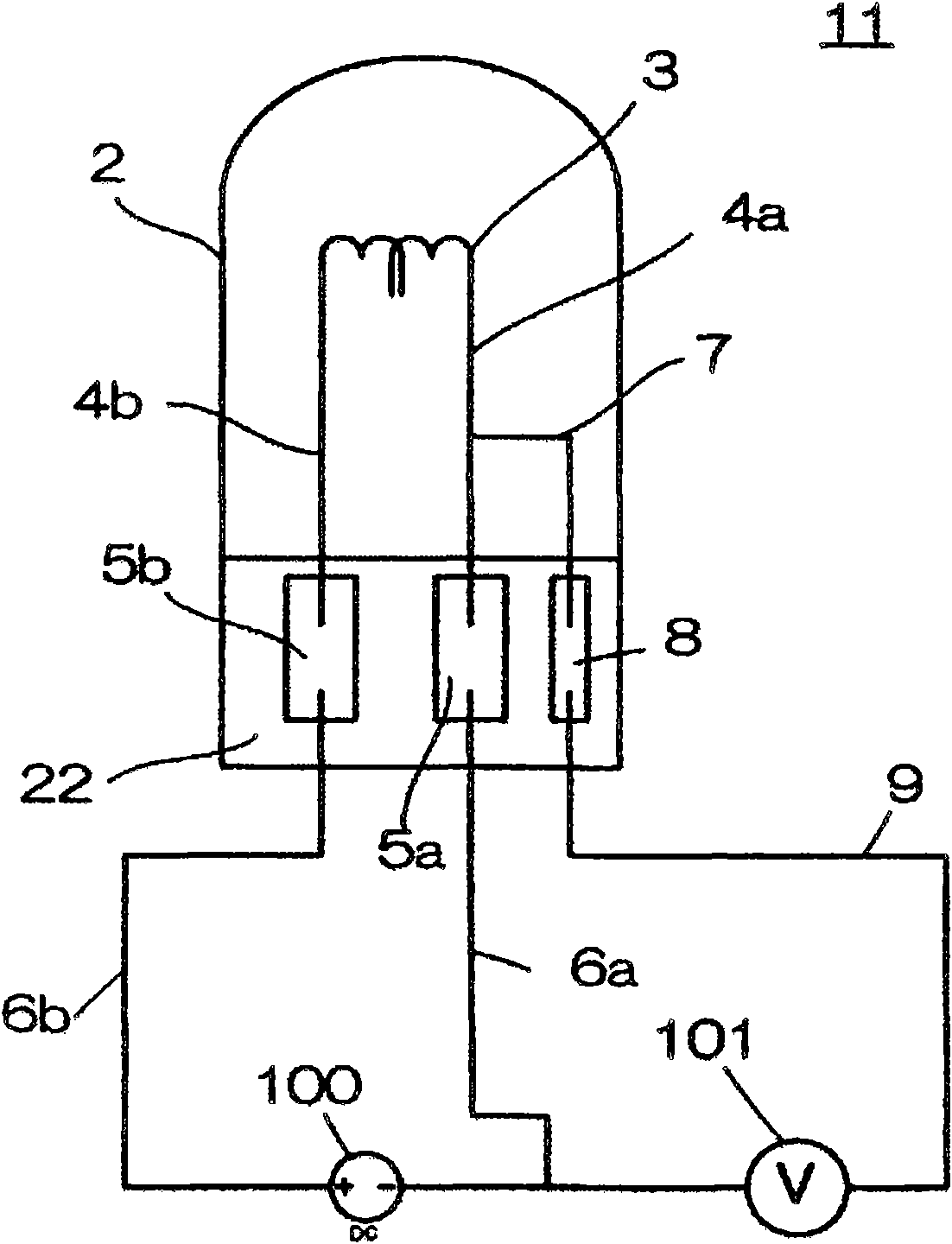

[0048] The first embodiment of the present invention will be described below. figure 1 It is an explanatory sectional view showing the lamp lighting device of the first embodiment.

[0049] The lamp lighting device is configured to include a filament lamp 10 , a power supply 100 for supplying power to the filament lamp 10 , and a voltage detector 101 connected in parallel to the external lead wire 6 a of the filament lamp 10 .

[0050] In the filament lamp 10, an AC power source with a rating of 100W to 10000W is connected to the external lead wires 6a and 6b drawn from both ends. The power supply 100 supplies an AC current to the filament 3 by connecting the external lead wire 6a drawn out from one sealing portion 21a and the external lead wire 6b drawn out from the other sealing portion 21b.

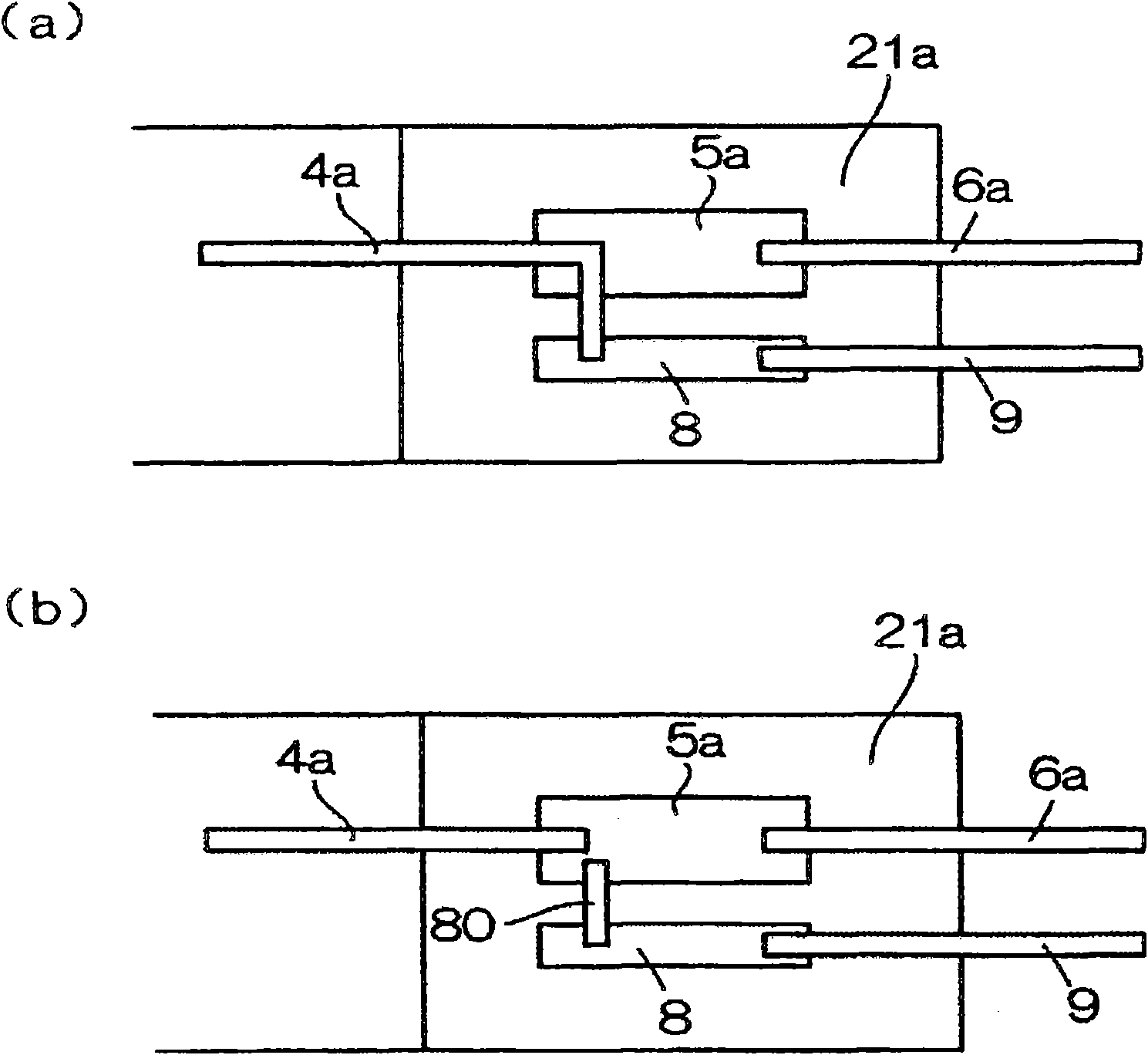

[0051] The filament lamp 10 is configured such that a coiled filament 3 is arranged inside a straight arc tube 2 made of quartz glass so as to extend in the tube axis direction. From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com