Preparation method of bracket with drug temperature-sensitive controlled-release function

A temperature-sensitive, drug-based technology, applied in stents, medical science, surgery, etc., to achieve the effects of good temperature sensitivity, controlled drug release function, strong operability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of amphiphilic block copolymer of thermosensitive polymer and degradable hydrophobic polymer

[0037] (1) Mix NIPAm and NHMAAm at a ratio of 7mmol: 1mmol, dissolve them in 10ml of tetrahydrofuran (THF), then add 0.04mmol of benzoyl peroxide (BPO) to the solution as an initiator, and 0.08mmol of mercaptoethanol as a chain transfer agent. agent, solution through N 2 Gas 20min;

[0038] (2) Then in N 2 Placed in a constant temperature water bath at 70°C under the protection of , and reacted with electromagnetic stirring for 7 hours;

[0039] (3) After the reaction solution is cooled, remove impurities by suction filtration;

[0040] (4) 8-10 times the volume of diethyl ether is used as a precipitating agent, after several times of dissolution, precipitation, and vacuum drying to obtain a white powder.

[0041] (5) Copolymerize the prepared methylolacrylamide and N-isopropylacrylamide with polycaprolactone (PCL) according to the ratio of 1:4 (molar ratio)...

Embodiment 2

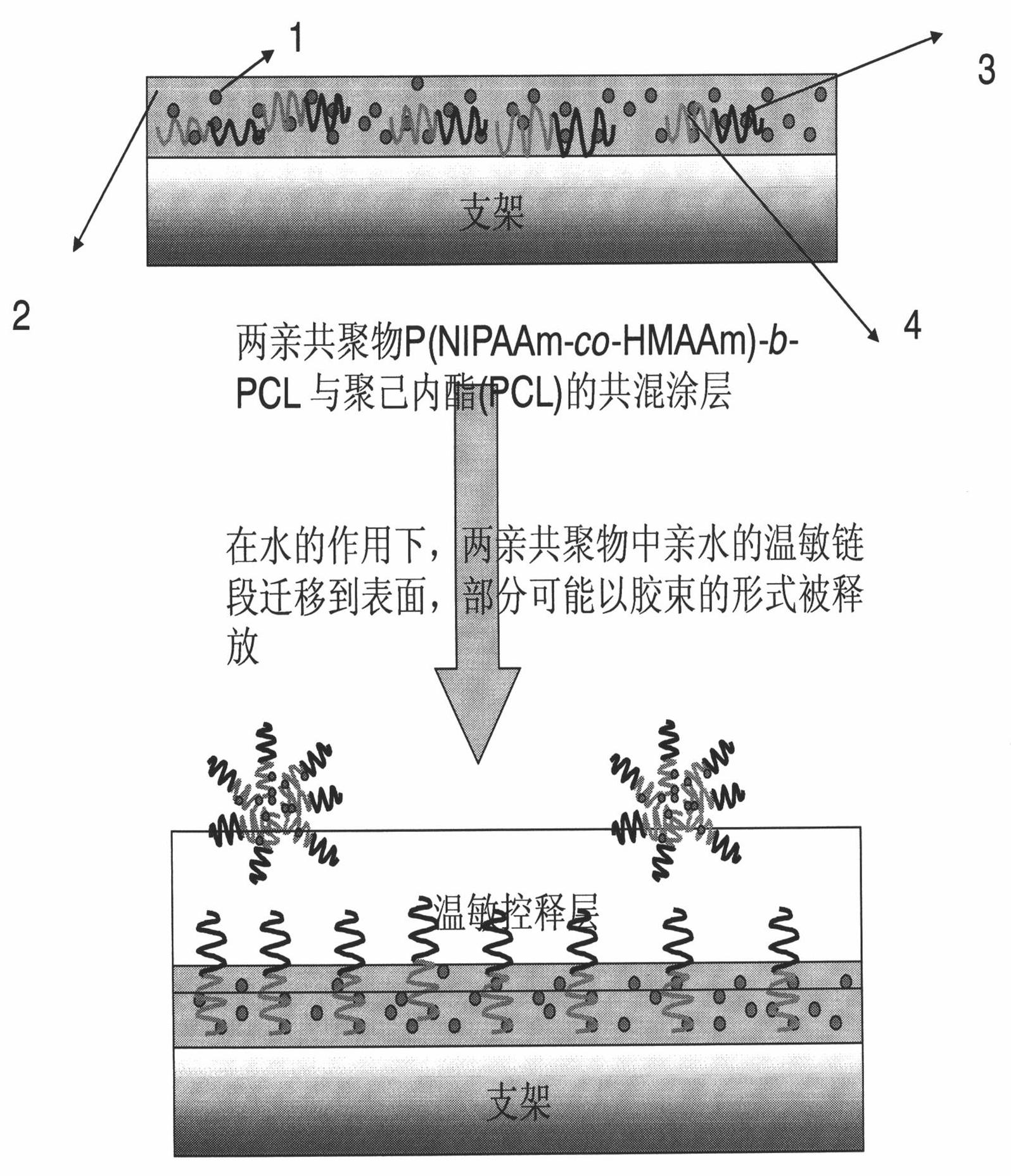

[0051] For the description of the advantages of the coating and stent with drug temperature-sensitive controlled release effect prepared by the method of the present invention, please refer to figure 2 , figure 2 It is a schematic diagram of the drug release principle of the stent with drug temperature-sensitive controlled release. 1 in the figure: small particles represent the drug; 2: uniform coating represents the PCL coating; 3: represents the temperature-sensitive part; 4: represents the PCL part in the amphiphilic copolymer. It should be noted that most of the current drug-eluting stents are directly coated with hydrophobic polymers such as polylactic acid and polycaprolactone to load drugs, and the drug release cannot be controlled by this coating. The present invention utilizes the synthesized temperature-sensitive copolymer and polycaprolactone as the mixed drug coating carrier. Under the action of water, the hydrophilic temperature-sensitive segment will migrate t...

Embodiment 3

[0053] 1. Preparation of amphiphilic block copolymer of thermosensitive polymer and degradable hydrophobic polymer

[0054] (1) Mix NIPAm and NHMAAm at a ratio of 5mmol: 1mmol, dissolve them in 10ml of tetrahydrofuran (THF), then add 0.04mmol of benzoyl peroxide (BPO) to the solution as an initiator, and 0.10mmol of mercaptoethanol as a chain transfer agent. agent, solution through N 2 Gas 20min;

[0055] (2) Then in N 2 Placed in a constant temperature water bath at 70°C under the protection of , and reacted with electromagnetic stirring for 7 hours;

[0056] (3) After the reaction solution is cooled, remove impurities by suction filtration;

[0057] (4) 8-10 times the volume of diethyl ether is used as a precipitating agent, after several times of dissolution, precipitation, and vacuum drying to obtain a white powder.

[0058] (5) Prepare the copolymer and polycaprolactone (PCL) according to the ratio of 1:6 (molar ratio), and react at 180°C for 24 hours to obtain the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com