Engine air cylinder cap and crankshaft box ventilation circulation system

A technology for engine cylinders and cylinder head covers, applied in crankcase ventilation, engine components, machines/engines, etc., can solve problems such as difficult to guarantee oil-gas separation effect, high pressure loss in gas flow, redundant structure, etc., and achieve compact structure, The effect of reducing the ineffective pressure loss and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

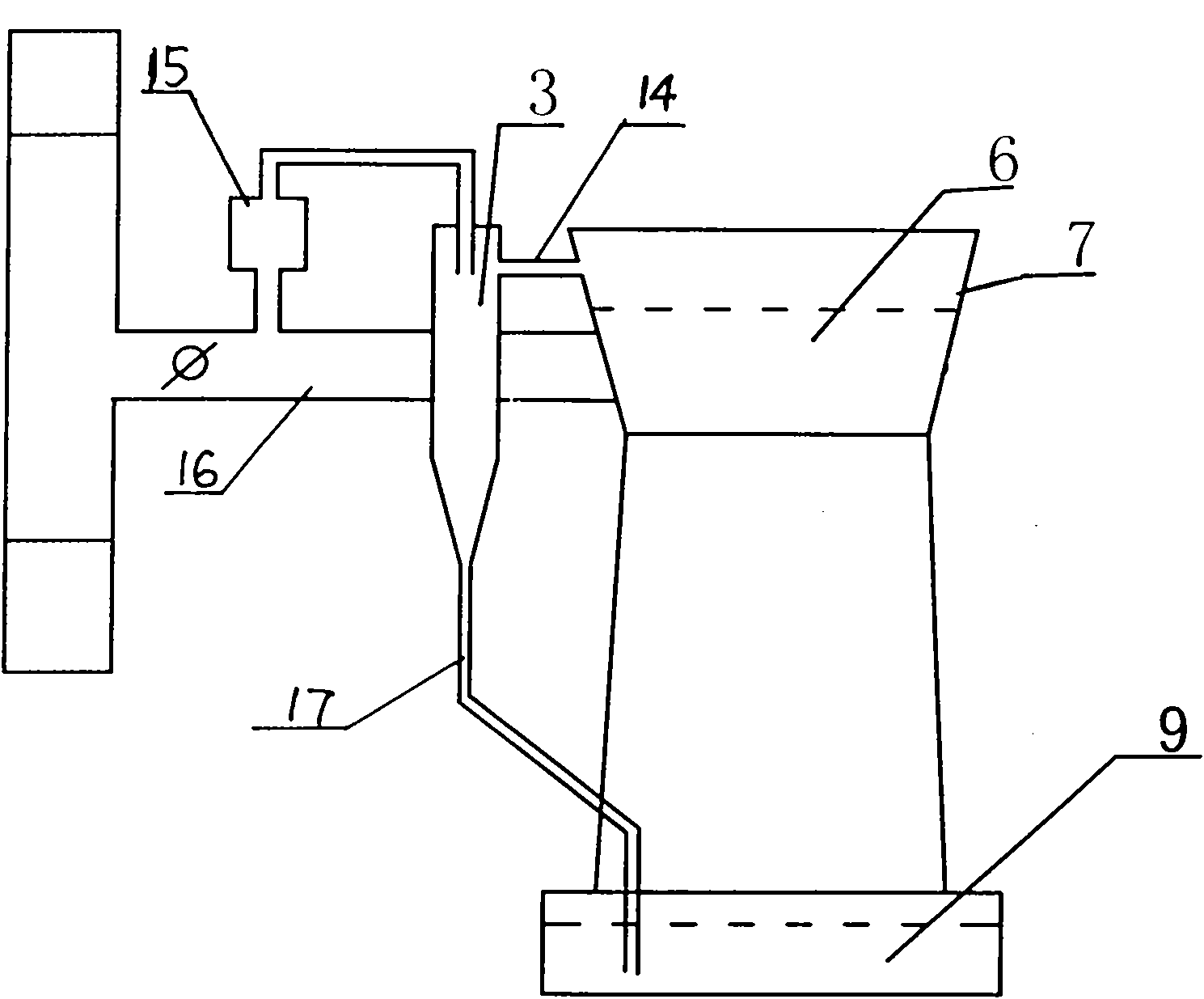

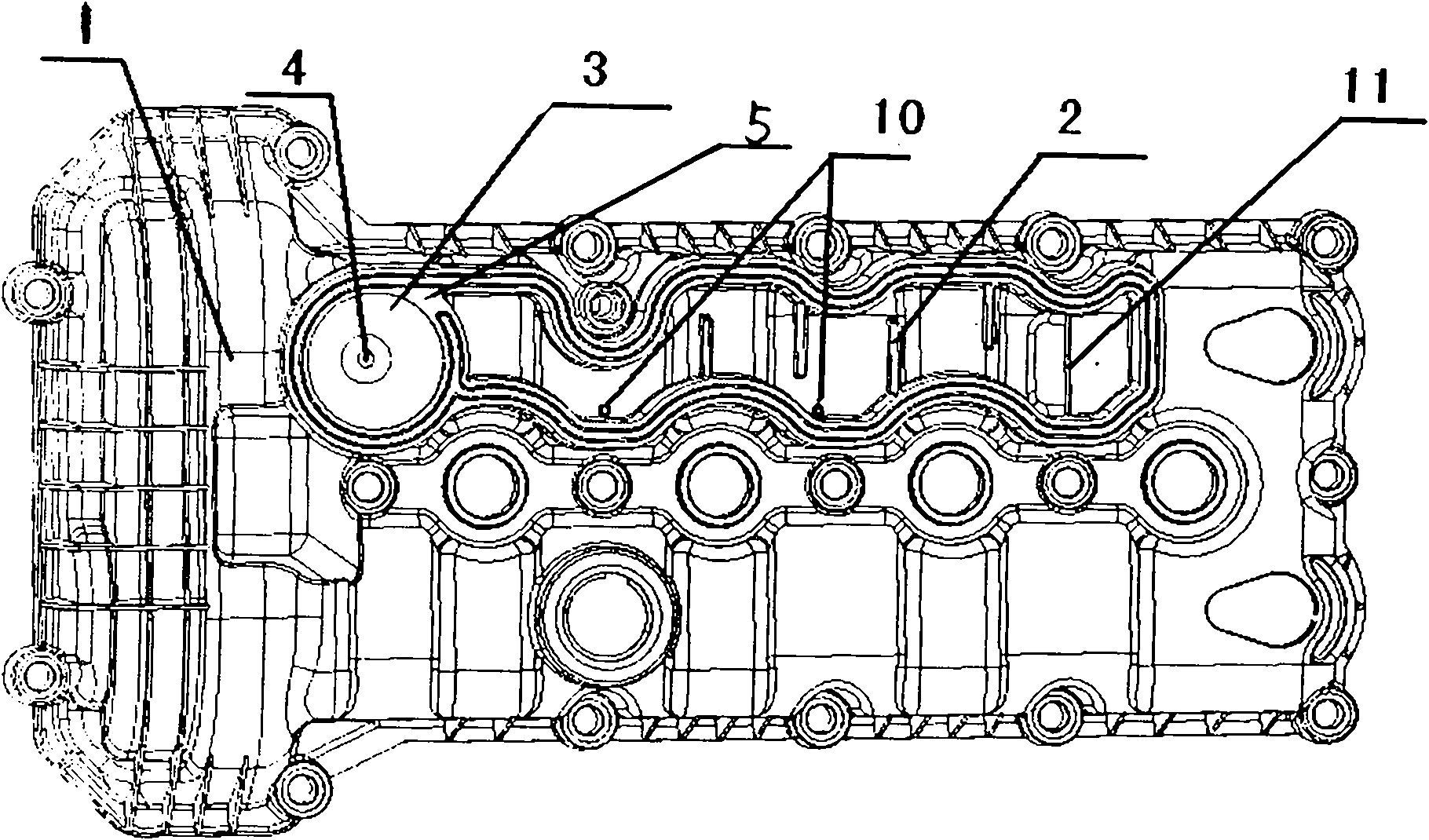

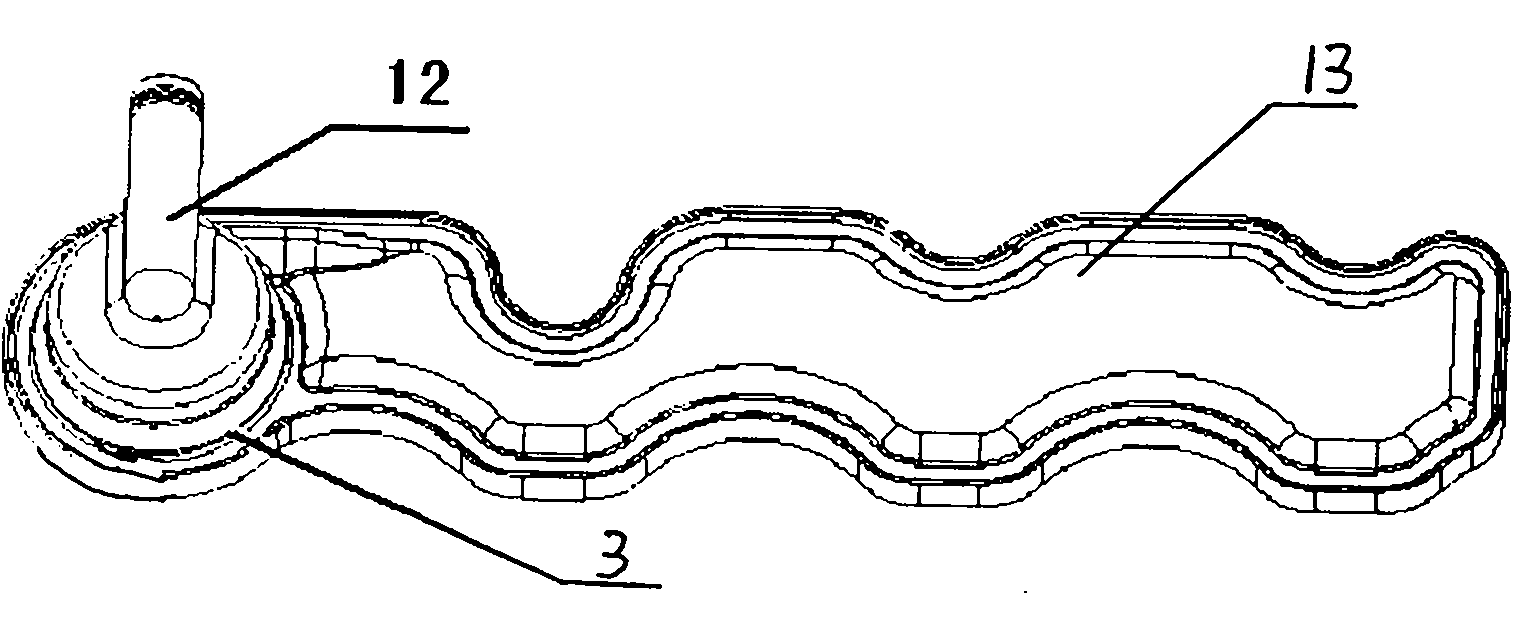

[0014] see figure 2 and image 3 , The cylinder head cover is made of artificial resin material, which includes the cylinder head cover body 1, cover plate 13, impact type oil-gas separation chamber 2, cyclone type oil-gas separation chamber 3 and oil return structure 4, etc. The impact type oil-gas separation chamber 2 is integrated in the cylinder head cover body 1, which passes through the elongated cavity in the cylinder head cover body 1 (the cavity is a concave cavity formed from the surface of the cylinder head cover) The multi-stage baffles are arranged staggeredly, and the cover plate 13 is welded on the cavity (that is, the cover plate 13 is welded on the surface of the cylinder head cover), which forms a labyrinth structure, and its air inlet is set in the impact oil-gas separation chamber 2, there is an oil return hole 10 leading to the camshaft chamber on the cover plate 13. At the other end of the impact-type oil-gas separation chamber 2, that is, at the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com