Presser foot for sewing machine

A sewing machine and presser foot technology, which is applied in the field of sewing machine presser feet, can solve the problems that the fabric control device cannot be applied to various types of sewing machines, etc., and achieve the effect of easy material, preventing thread skipping, and easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

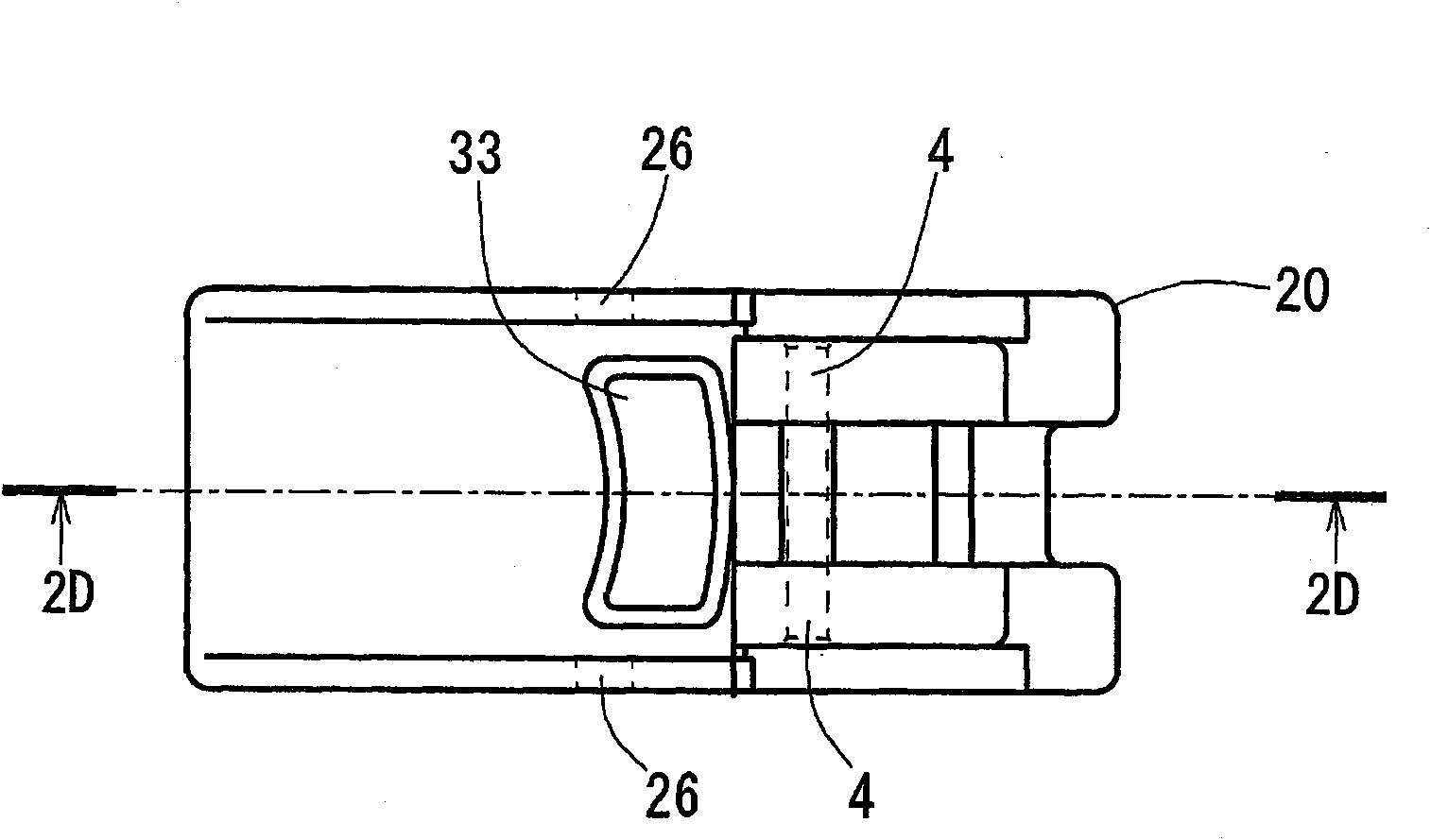

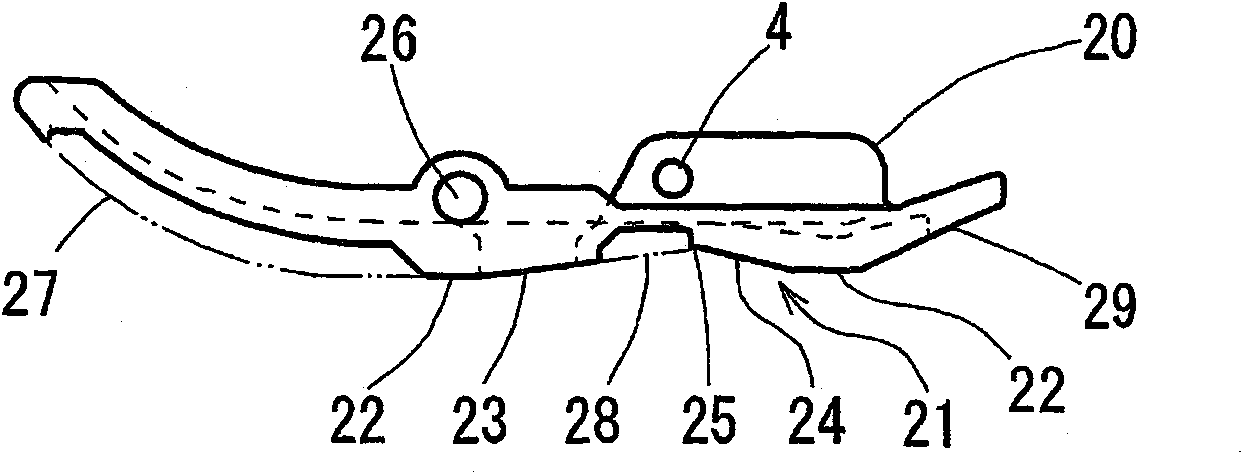

[0078] Hereinafter, a first embodiment of the presser foot 1 for a sewing machine disclosed herein will be described with reference to the drawings. In the following description, the up and down directions are vertical directions that coincide with the moving direction of the sewing needle 6 . The front and rear directions correspond to the feeding direction of the processing material in the sewing machine. The left and right sides in the drawings correspond to the forward and backward directions, respectively.

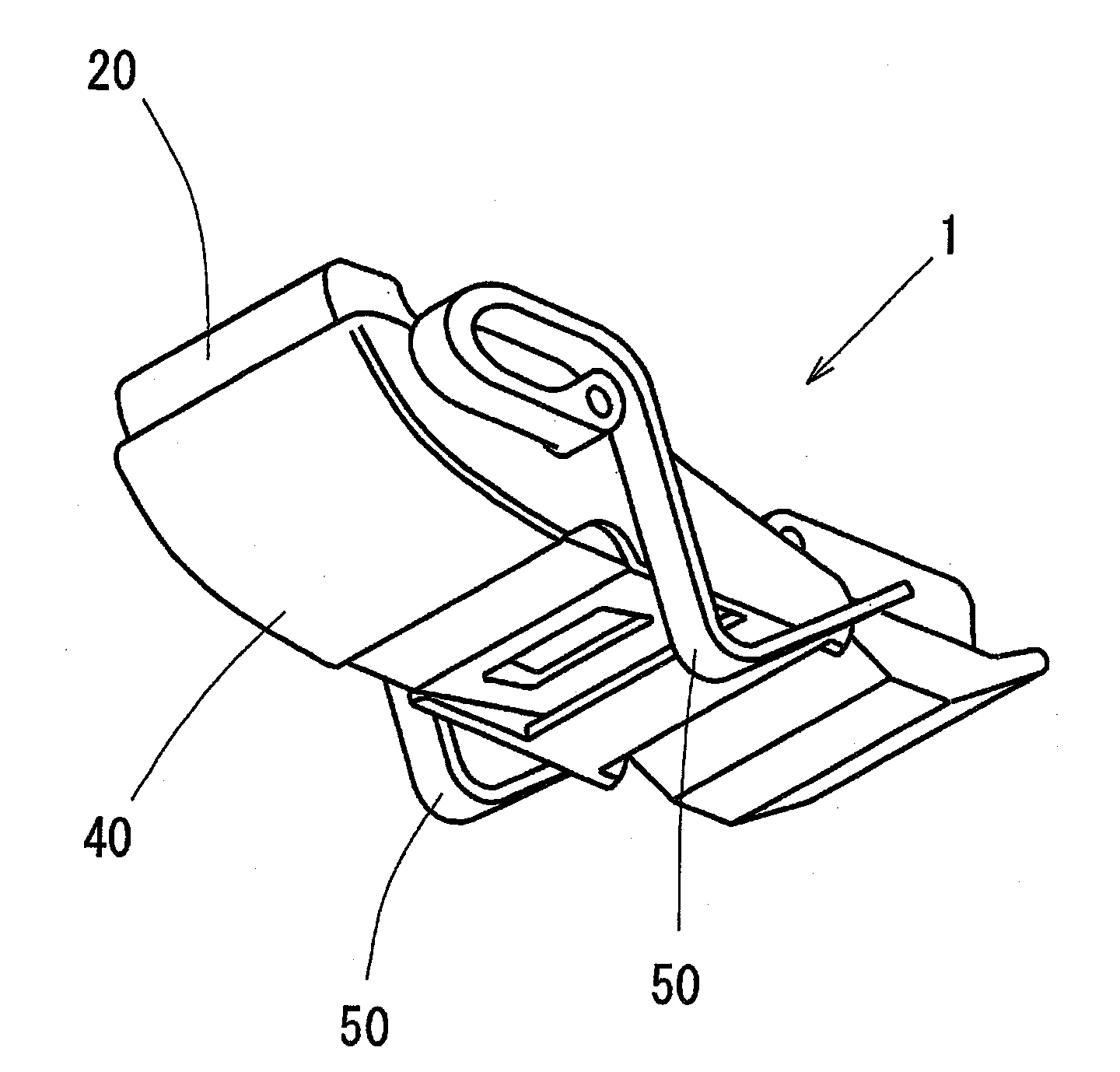

[0079] figure 1 is a perspective view of the presser foot 1 according to the first embodiment. The presser foot 1 includes a main body 20 , a restricting member 40 for restricting vertical movement of a processed material, and two leaf springs serving as restricting portions (elastic members) 50 attached to the restricting member 40 . The vertical movement of the processed material resembles an undulating flag and is henceforth referred to as "fluttering". Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com