Method for compensating coiling tension of medium-width steel belt formed by cold continuous rolling

A technology for coiling tension and compensation methods, applied in tension/pressure control, metal rolling, metal rolling, etc., can solve problems affecting production rhythm and product quality, save online processing time, be easy to implement, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

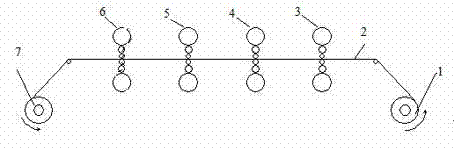

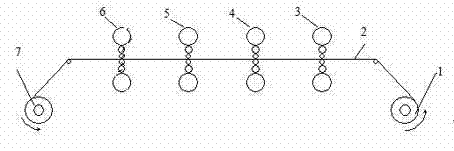

[0020] Refer to attached figure 1 , in an embodiment, after the rolled steel strip 2 on the uncoiler 1 passes through 1# frame 3, 2# frame 4, 3# frame 5, and 4# frame 6, it is coiled by the coiler 7 .

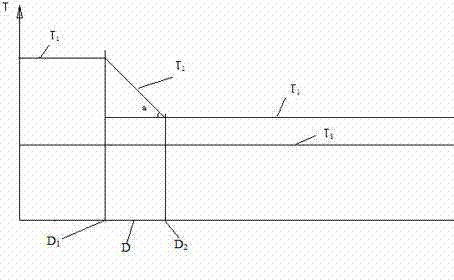

[0021] Refer to attached figure 2 , the present invention is divided into three grades according to the thickness of the steel strip at the exit of the rolling mill, the first grade is the thickness h0.80mm; it is determined according to the thickness grade δ 1 ,δ 2 、D 1 、D 2 Tension compensation parameters, establish a database of tension compensation parameters.

[0022] The automatic realization of the present invention is that the corresponding PLC writing control program of rolling mill coiler reaches T 1 , T 2 , T 3 Calculation, output and control. Set tension T S The initial value of is imported from the model calculation valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com