Preparation method of novel quinone amine curing agent and application to normal temperature epoxy curing system

A technology of curing agent and quinone amine, which is applied in the preparation of new quinone amine curing agent and in the application field of epoxy curing system at room temperature, and can solve the problem of high price of polyether amine or isophorone diamine and the synthesis process of quinone amine Complicated, difficult to use and other problems, to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

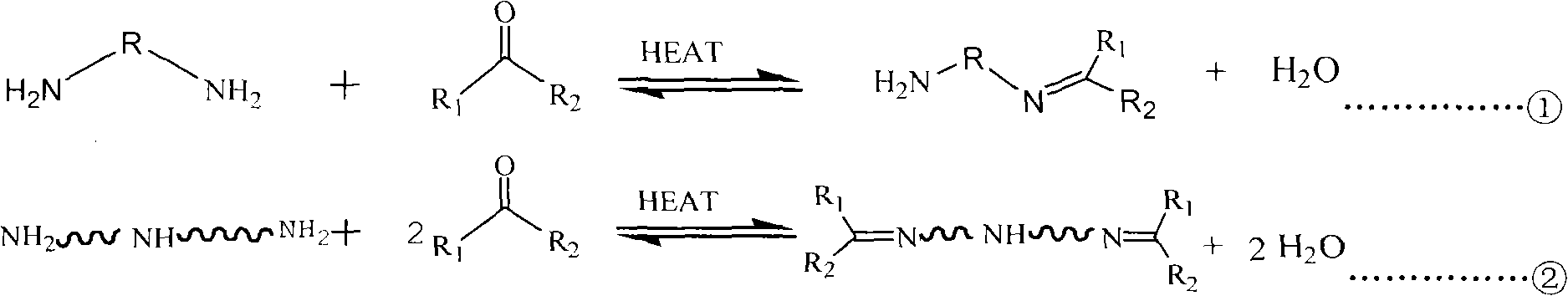

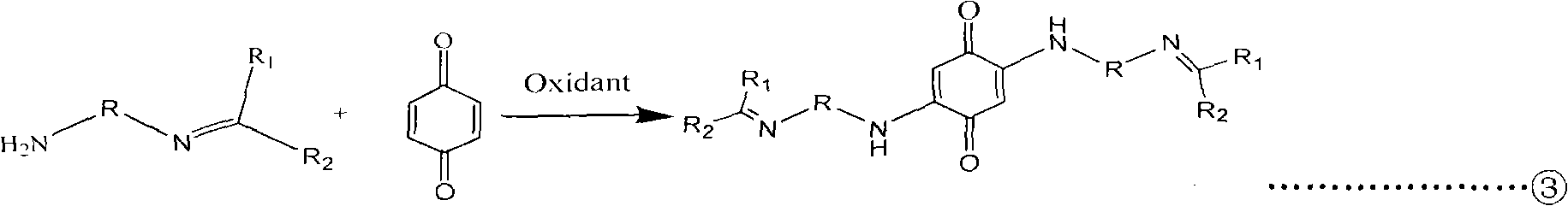

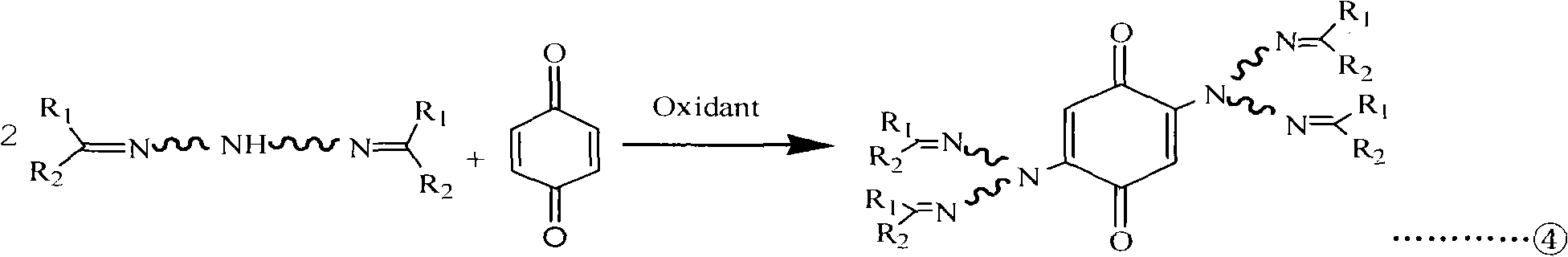

Method used

Image

Examples

Embodiment 1

[0030] 1. Imination of amines

[0031] Add 60 grams of ethylenediamine, 0.3 grams of 723 cation exchange resin, and 73.1 grams of DMF solution into a three-necked flask equipped with a stirrer and a condenser, add 50 milliliters of cyclohexane solution, and reflux at a temperature of 80 ° C to separate water. When the quality of the dewatered water is very close to the theoretical value of 18 grams, the temperature of the reaction system is increased to 130-140 °C, and the cyclohexane solution and the DMF solution that has not participated in the reaction in the system are removed by distillation under reduced pressure, and the product is stored in Dry inside the brown bottle.

[0032] 2. Preparation of quinone amine curing agent

[0033] 15.2 grams of the above product were added to a dry constant pressure funnel, 10.8 grams of benzoquinone was dissolved in the tetrahydrofuran solution, and the contents in the funnel were slowly added dropwise to the tetrahydrofuran solution...

Embodiment 2

[0036] 1. Imination of amines

[0037] Add 79.1 grams of trimethylhexamethylenediamine, 52.6 grams of methyl isobutyl ketone, 0.3 grams of 723 cation exchange resin and 50 milliliters of benzene solution in the there-necked flask equipped with agitator, water separator, and condensing tube. Reflux at 80°C to separate water. When the quality of the separated water is very close to the theoretical value of 9 grams, the temperature of the reaction system is increased to 115-125° C., the ketone and the system solvent benzene that do not participate in the reaction are evaporated, and the product is stored in a dry brown bottle.

[0038] 2. Preparation of quinone amine curing agent

[0039] 15.6 grams of the above product were added to a dry constant pressure funnel, 5.4 grams of benzoquinone was dissolved in the THF solution, and the contents of the funnel were slowly added dropwise to the THF solution of benzoquinone while stirring. After the dropwise addition, 2 g of calcium h...

Embodiment 3

[0042] 1. Imination of amines

[0043] Add 30 grams of ethylenediamine, 43.9 grams of DMF and 0.3 grams of 723 cation exchange resin into a clean and dry 500ml three-necked flask equipped with a stirring device, a condenser, and a water separator, and then add 50 milliliters of cyclohexane. Remove the generated water azeotropically, measure the amount of distilled water to control the reaction process, raise the temperature of the system to 115-125°C when the amount of water collected is close to 9 grams, and remove unreacted DMF and toluene by distillation under reduced pressure to obtain one end A ketimine-modified polyamine AP whose group is a tertiary amino group.

[0044] 2. Preparation of quinone amine curing agent

[0045] 24.6 grams of the above product were added into a dry constant pressure funnel, 10.8 grams of benzoquinone was dissolved in the THF solution, and the contents of the funnel were slowly added dropwise to the THF solution of benzoquinone while stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com