Sounding module and sounding device using same

A sounding device and module technology, applied in the direction of sensors, electrical components, sensor parts, etc., to achieve the effect of prolonging the service life and reducing the influence of the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The sound generating device of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

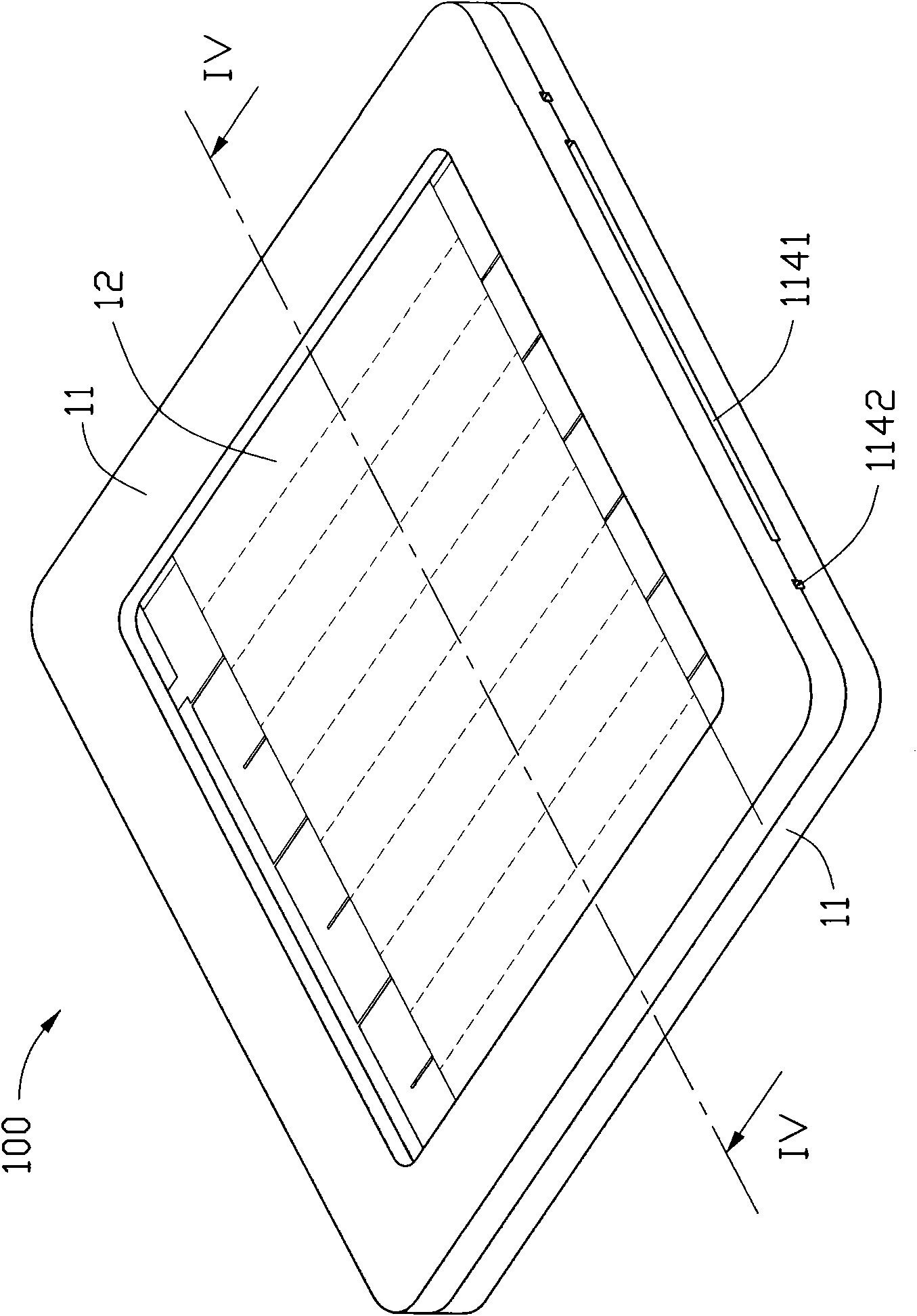

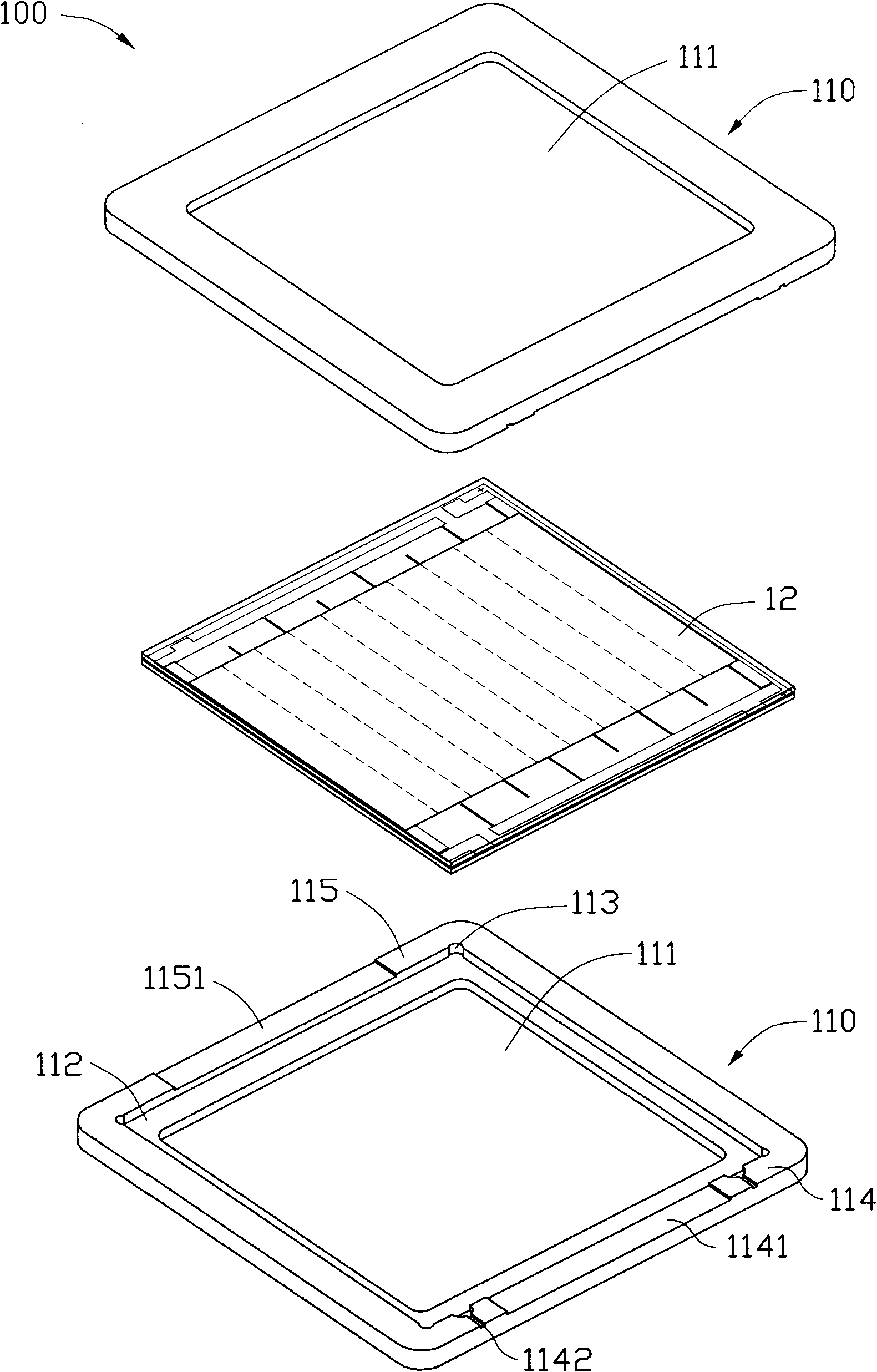

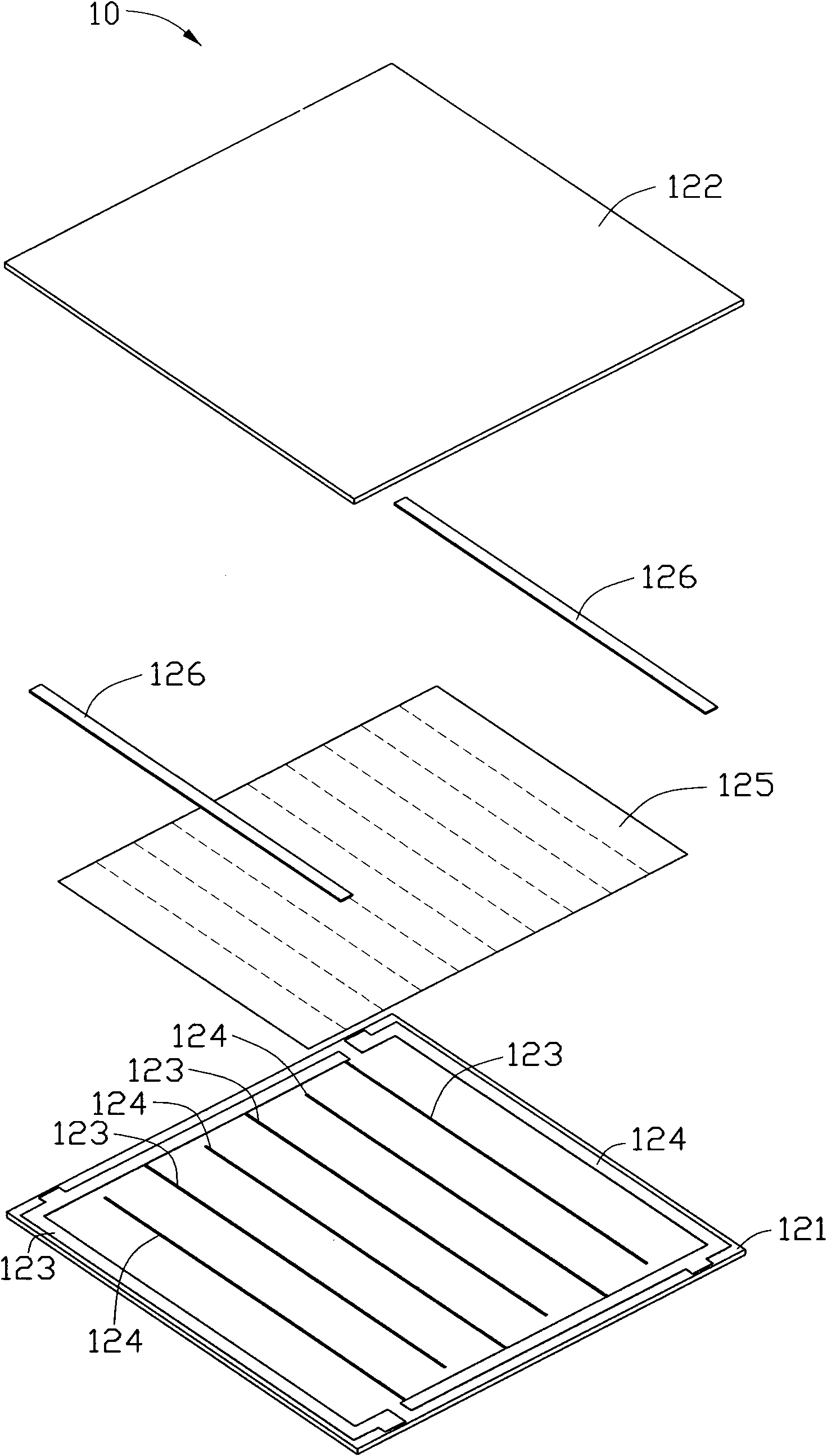

[0018] see figure 1 , The first embodiment of the present invention provides a sound generating device 100, which includes a fixing frame 11 and a sound generating module 12, and the fixing frame 11 clamps and fixes the sound generating module 12 therebetween.

[0019] see figure 2 , the fixed frame 11 includes two frame bodies 110 located on both sides of the sound module 12, and the two frame bodies 110 are interlocked to sandwich the sound module 12 therebetween. The two frame bodies 110 can also be connected by means of screwing, bonding, riveting and the like.

[0020] The two frames 110 have the same structure and are arranged symmetrically with respect to the sound module 12. Each frame 110 is surrounded by four frames connected end to end, and the four frames are surrounded by an opening 111, and the opening 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com