Three-degree of freedom flexible precision positioning workbench

A technology of precise positioning and degrees of freedom, applied in the field of micro-operating systems, can solve the problems of uneven distribution of imprinting force, limitation of machining accuracy and quality, easy stretching and deformation of silicone, etc. Linear, assembly-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments, structures, features and effects provided according to the present invention will be described in detail below with reference to the accompanying drawings and examples.

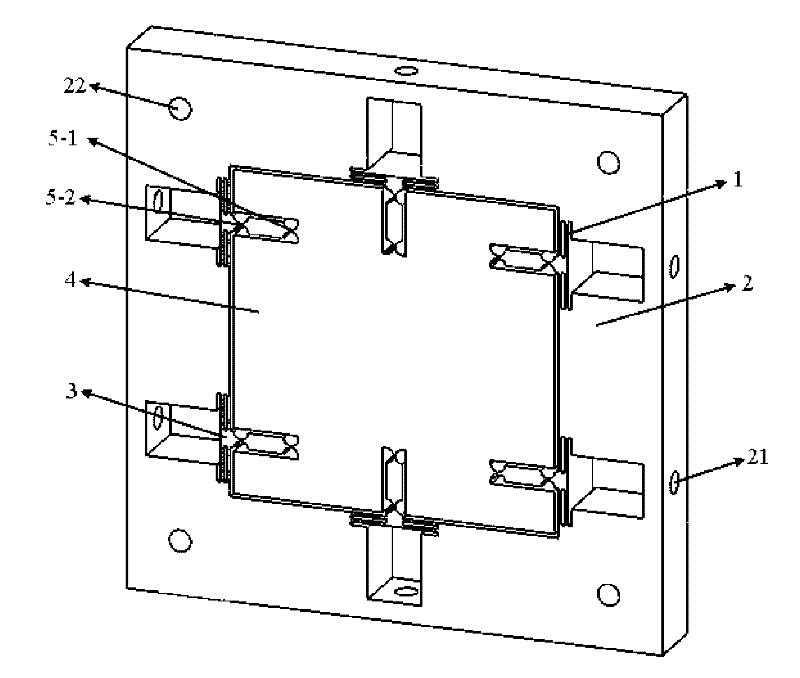

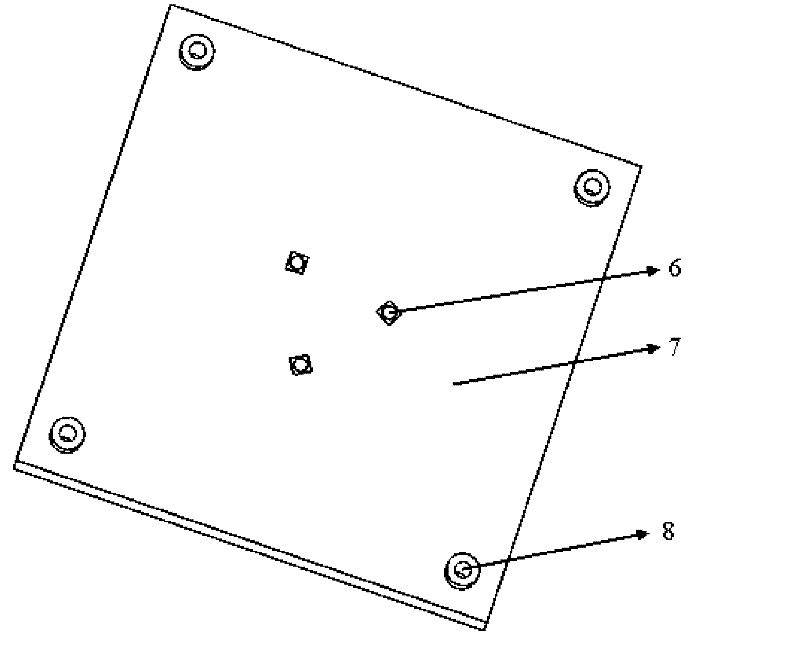

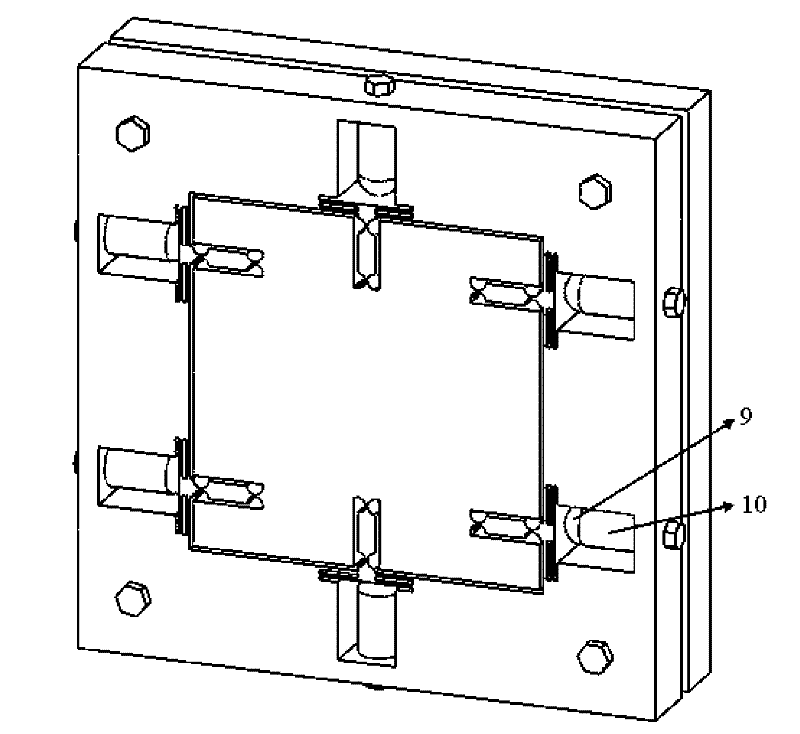

[0019]see Figures 1 to 4 , a three-degree-of-freedom precision positioning stage for nanoimprint lithography systems. It includes a rigid support 7 and a base 2 connected to the top of the rigid support 7. A moving platform 4 with a rectangular cross-section is connected in the middle of the base 2 through six flexible branches. Two of the six flexible branched chains are respectively arranged along the centerline direction of the upper and lower opposite sides of the moving platform 4, and the other four flexible branched chains are located at the left and right opposite sides of the moving platform respectively and in two groups. The left and right two sets of flexible branch chains are arranged symmetrically with respect to the vertical axis of symmetry of the moving plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com