Fruit sleeve separation method

A separation method, technology of fruit sleeves, applied in the field of transformation of apple selection automatic production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

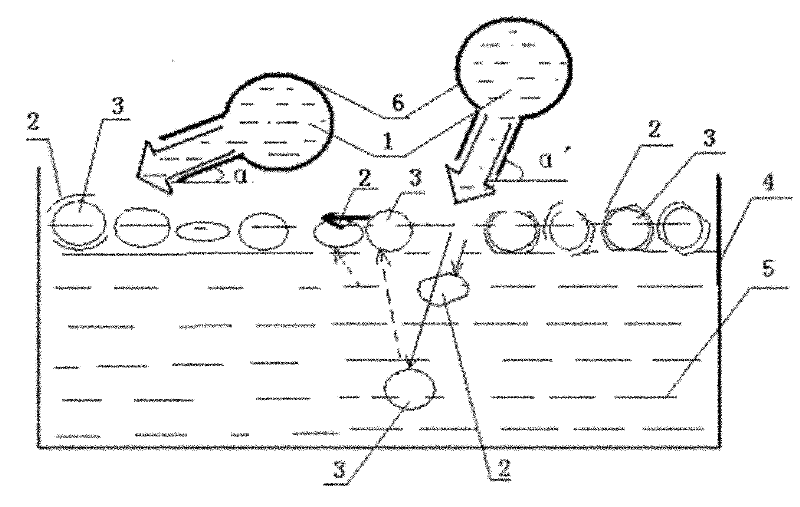

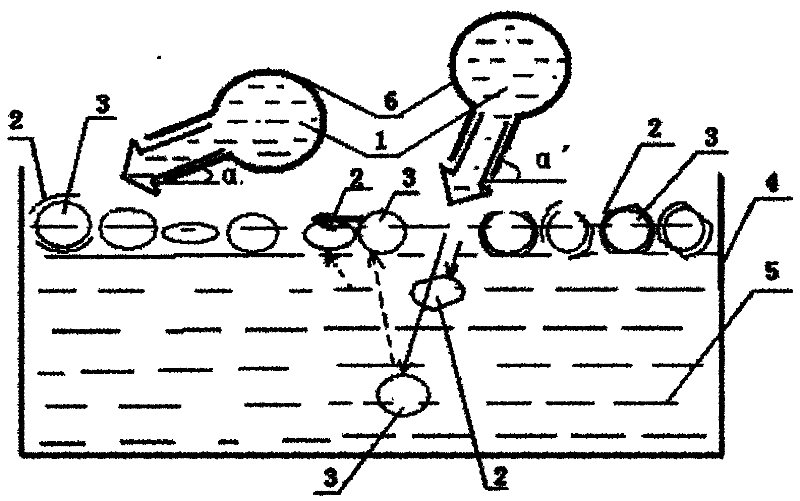

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

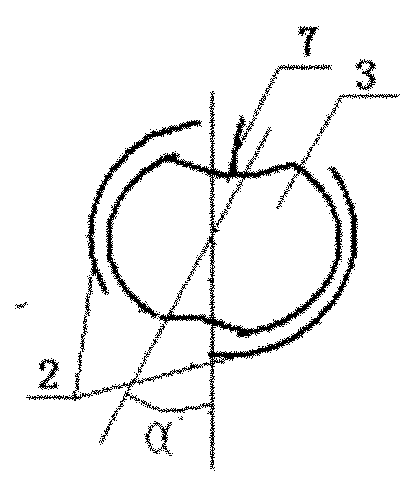

[0011] First analyze the characteristics of the apple 3 with the plastic foam protective cover 2 floating on the surface of water (hereinafter referred to as disinfectant). In fact, these plastic foam protective covers 2 for the purpose of protecting the apple 3 from mechanical damage are attached to the outside of the apple 3 with their own elastic bag, and are integrated with the apple 3 . At the scene of the disinfection process of the automatic production line, the plastic foam protective cover 2 and the apple 3 are integrated and float on the disinfectant solution, and move forward depending on the flow of the disinfectant solution, and each apple 3 is based on its own common characteristics. Basically, they float freely on the water surface facing upwards or downwards, and some of the fruit handles 7 of the apples 3 deviate from the vertical line, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com