Static hop-pocket mixed dust removal device and control method thereof

A technology of dust removal device and cloth bag, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of inability to control dust removal, difficulty in realization, complicated control, etc., and achieve the effect of economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

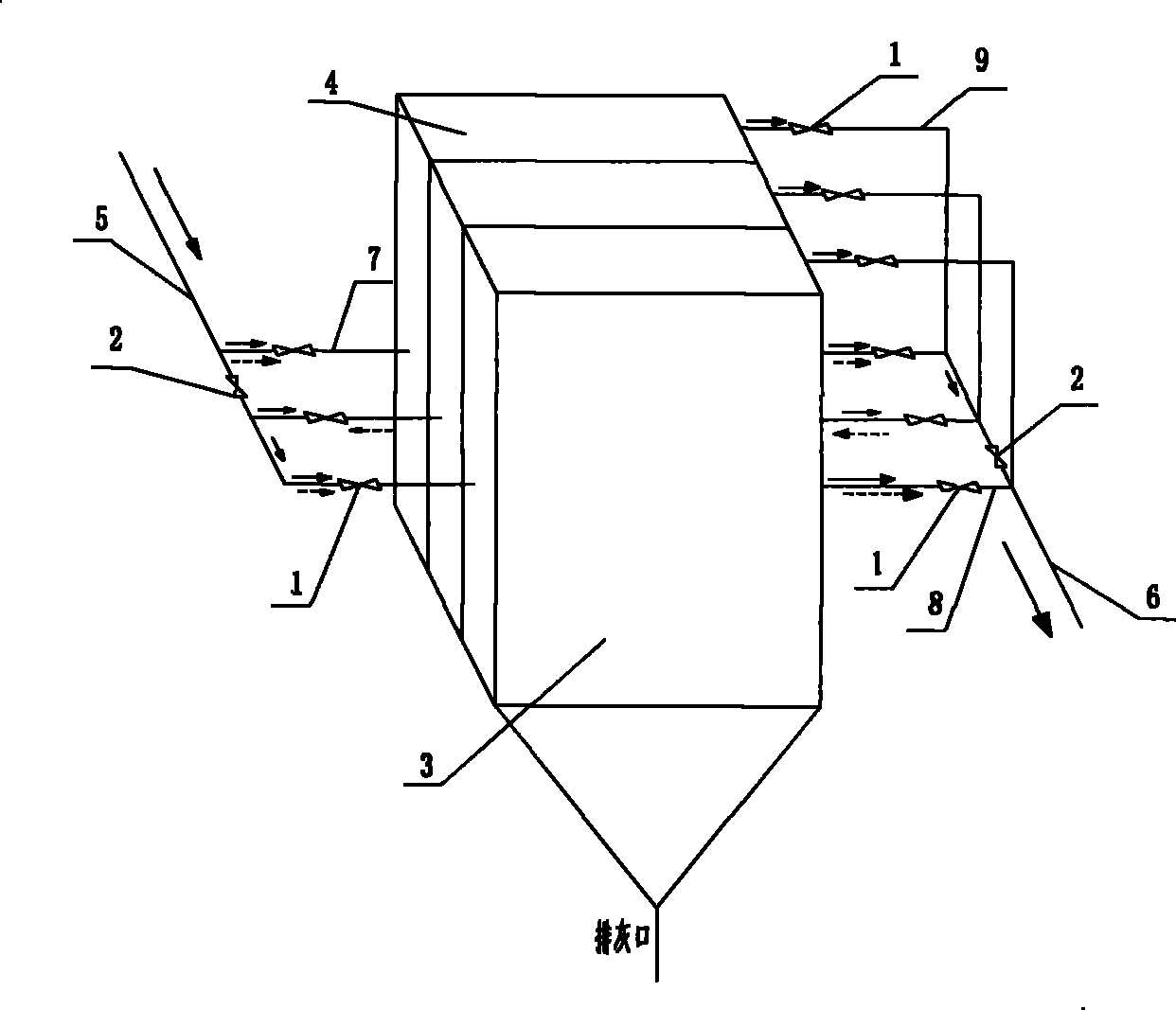

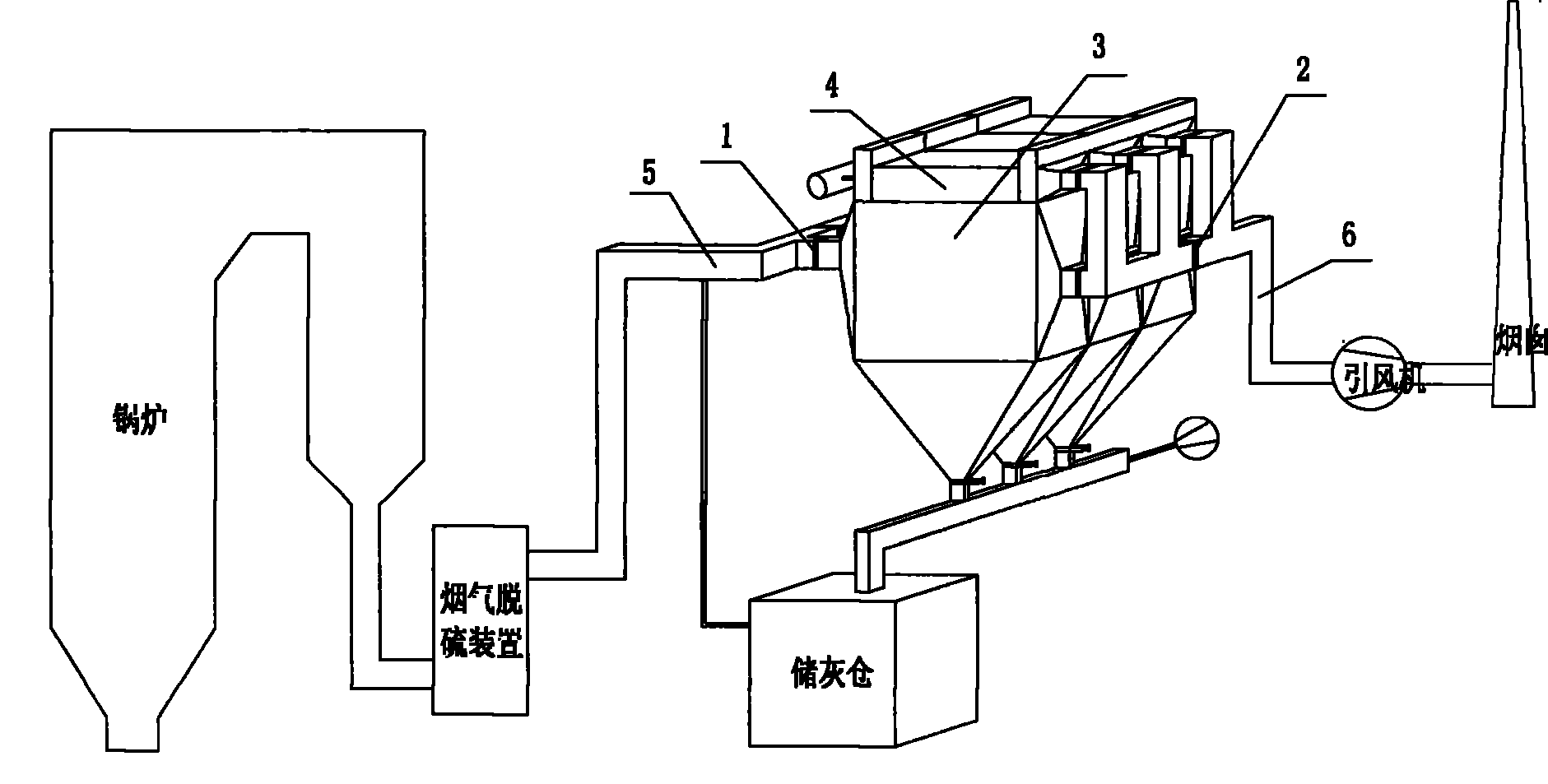

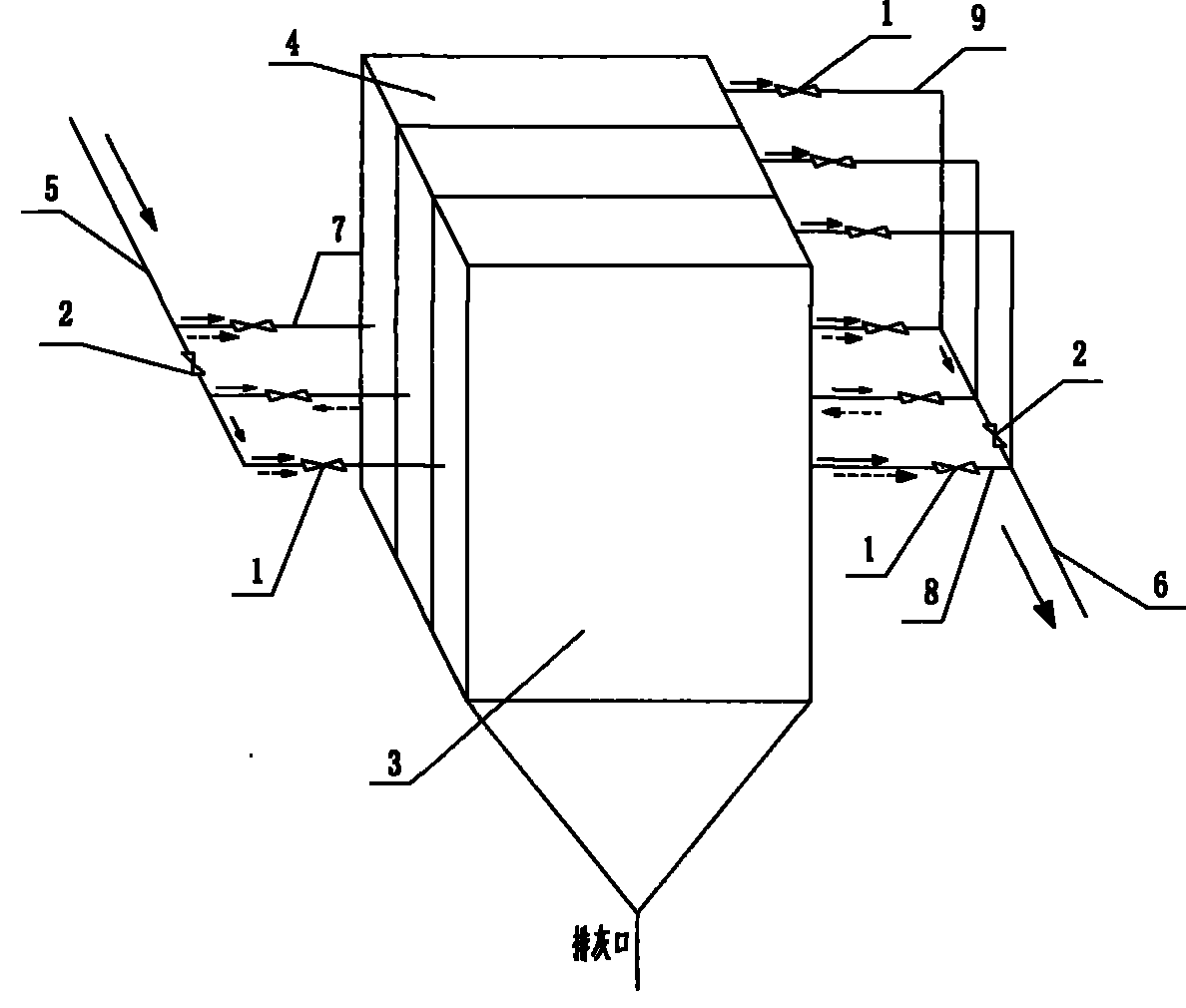

[0029] see figure 1 with figure 2 , the present invention includes three electrostatic bag mixing dedusting chambers 3 . The flue gas inlet of each electrostatic bag mixing dedusting chamber 3 is connected with the main flue 5 at the entrance through the inlet branch flue 7 equipped with the flue gas cut-off door 1 . The flue gas outlet of each electrostatic bag mixing dust removal chamber 3 is connected to the outlet main flue 6 through the outlet branch flue 8 equipped with a flue gas shut-off door 1, and the clean gas chamber 4 at the top of each electrostatic bag mixing dust removal chamber 3 passes through the outlet flue 8 equipped with flue gas The upper outlet branch flue 9 of the air cut-off valve 1 is also connected with the main outlet flue 6 . The inlet main flue 5 and the outlet main flue 6 are respectively equipped with flue gas connecting doors 2 on the main flue pipes between the adjacent front two entrance sub-flues 7 and between the adjacent rear two exit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com