Four-roller compact spinning device

A technology of compact spinning and rollers, which is applied to spinning machines, textiles, papermaking, and drafting equipment. costly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

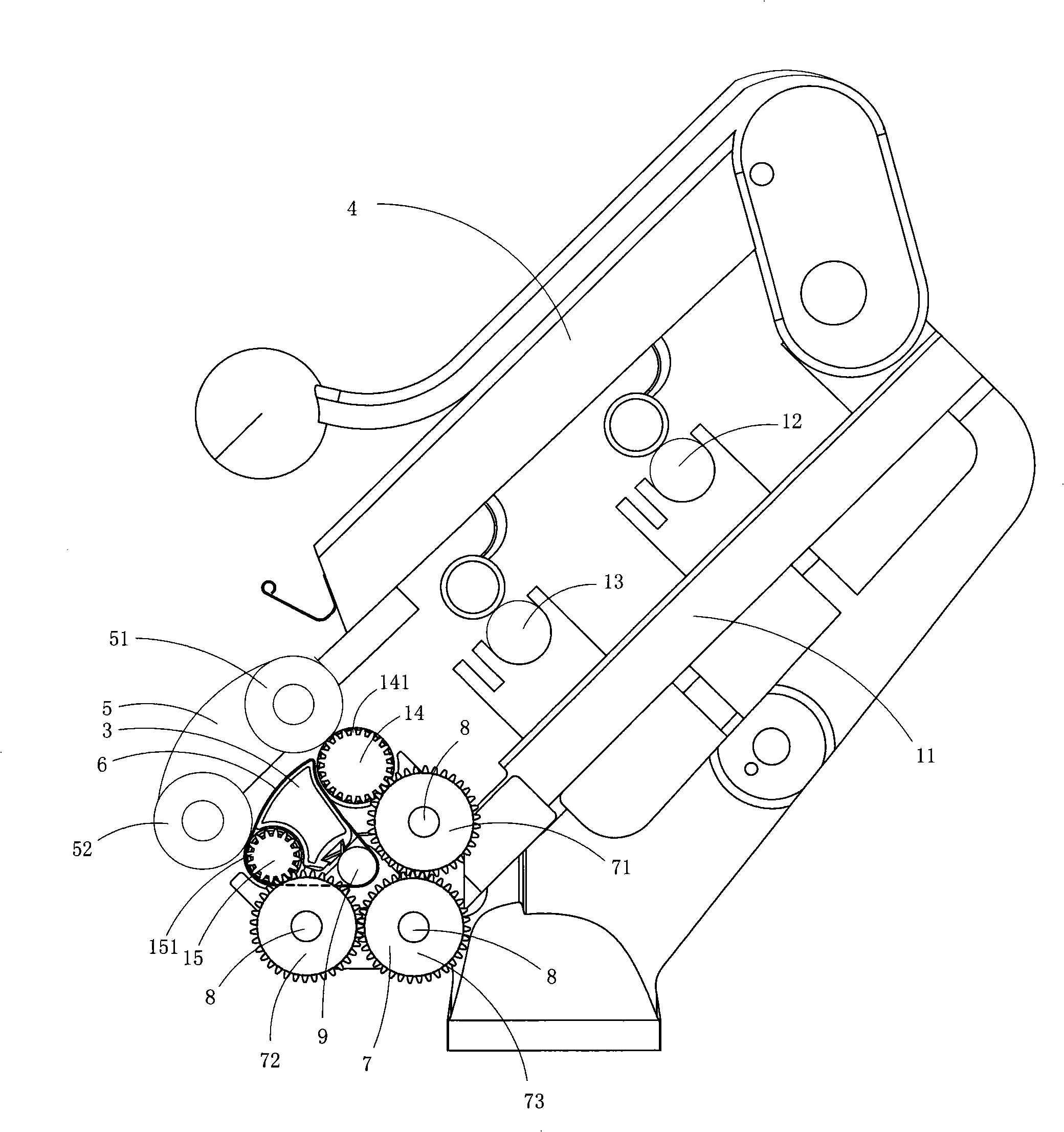

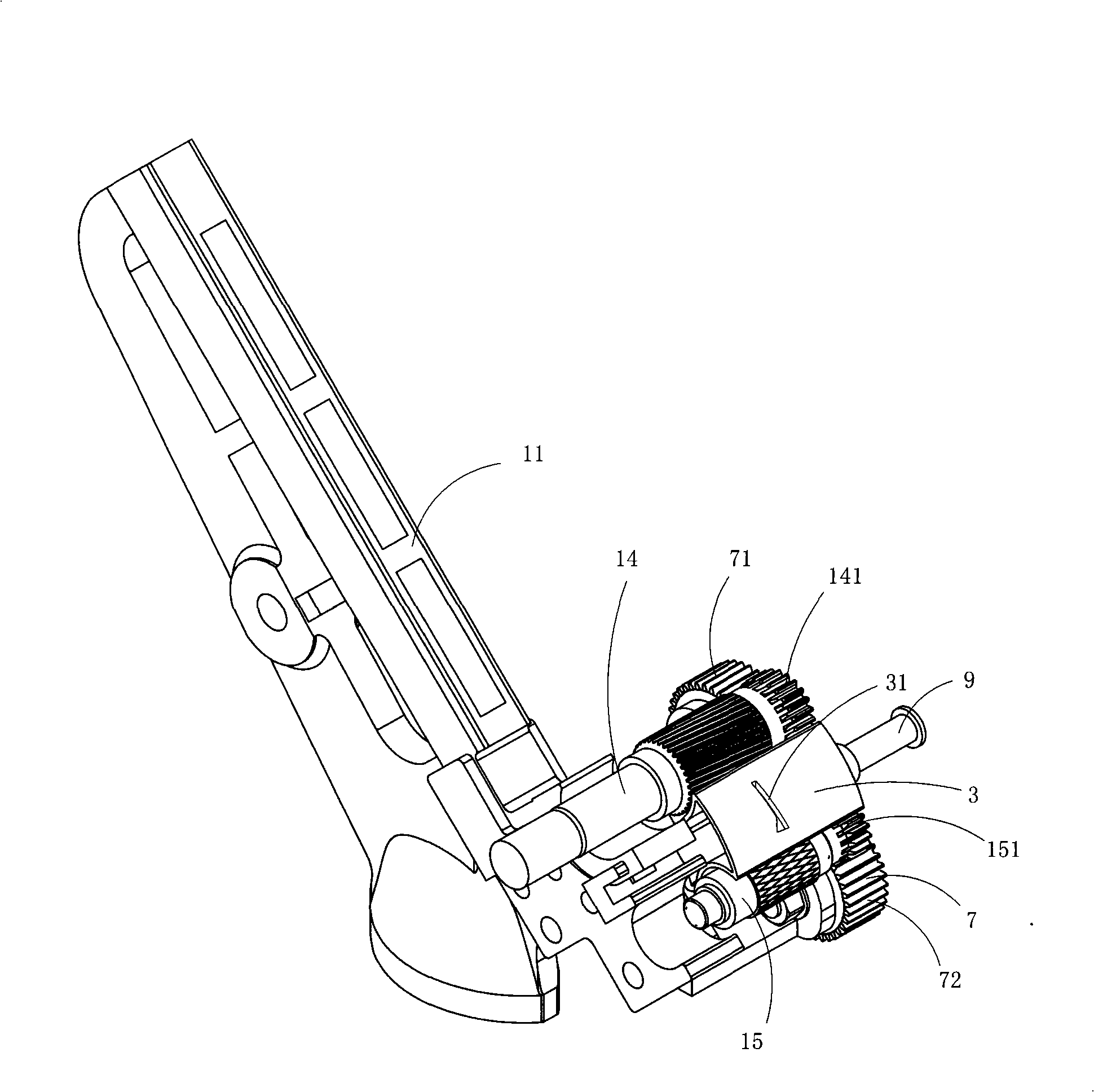

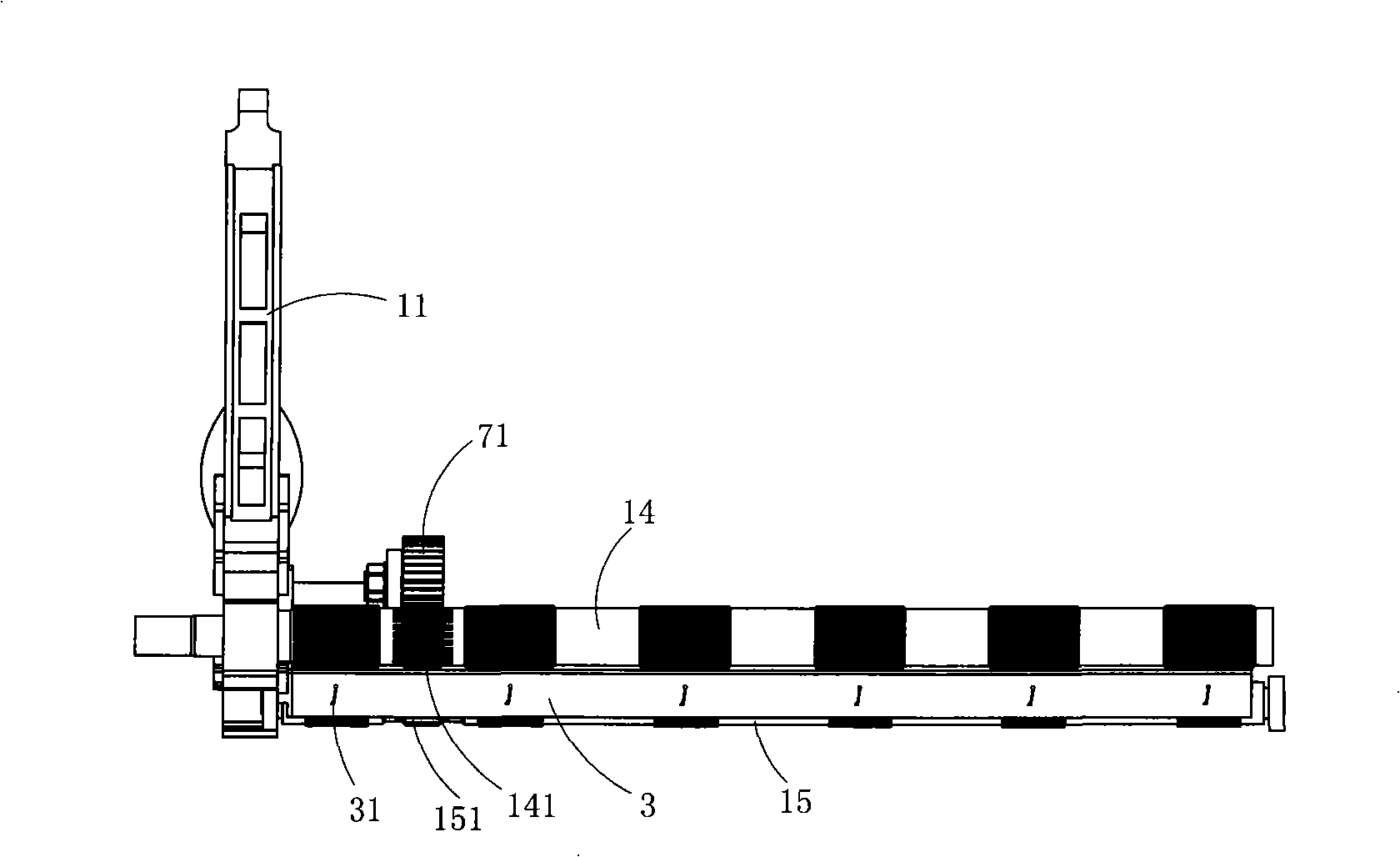

[0026] Figure 1 to Figure 3 A first embodiment of the invention is shown, in which figure 1 It is a structural schematic diagram of the present invention; figure 2 yes figure 1 A schematic diagram of a partial three-dimensional structure of the four-roller compact spinning device shown; image 3 yes figure 1A schematic diagram of the structure of the four-roller compact spinning device shown with some components removed.

[0027] This embodiment is a four-roller compact spinning device, see Figure 1 to Figure 3 , including roller seat 11, rear roller 12, middle roller 13, front roller 14, output roller 15, gathering pipe 3, cradle 4, saddle frame 5, front roller top roller 51, output top roller 52, grid ring 6 and A bridge gear assembly 7 arranged below the collecting pipe 3; the rear roller 12, the middle roller 13, the front roller 14, the collecting pipe 3 and the output roller 15 are sequentially arranged on the roller seat 11 along the advancing direction of the y...

Embodiment 2

[0034] Figure 4 It is a structural schematic diagram of the second structure of the present invention, showing the second specific implementation mode of the present invention.

[0035] This embodiment is basically the same as Embodiment 1, except that the bridge gear assembly 7 is arranged below the end pipe section at one side of the collecting pipe 3 . Described front roller gear 141 is a gear that is assembled on the front roller 14, and described front roller 14 is split piece; Described output roller gear 151 is a gear that is assembled on the output roller 15, and described output roller 15 is split parts.

[0036] The advantage of this embodiment is that the output roller gear 151 and the front roller gear 141 are replaceable gears, and the maintenance operation cost is low.

Embodiment 1 and Embodiment 2

[0037] Embodiment 1 and embodiment 2 have the following advantages:

[0038] (1) In Embodiment 1 and Embodiment 2, when spinning yarns of different materials, different draft ratios need to be set, so that the ratio of the linear speed of the front roller to the linear speed of the output roller remains at one Within the appropriate range, that is to say, it is necessary to adjust the transmission of the front roller gear, the bridge gear and the output roller gear; and the traditional three-gear structure of the four-roller compact spinning device, because the front roller gear is directly processed on the front roller The output roller gear is directly processed on the output roller, and its diameter, number of teeth and position are already fixed, so that the adjustment of the draft ratio by changing the structure of the bridge gear alone is greatly restricted and difficult to adjust Even can not be adjusted; and if change both or all of the front roller gear, the bridge ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com