Elevator maintenance system

A technology for elevator maintenance and objects, applied in elevators, transportation and packaging, etc., can solve problems such as poor ride quality, unfavorable service, and increased number of dispatches of maintenance personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

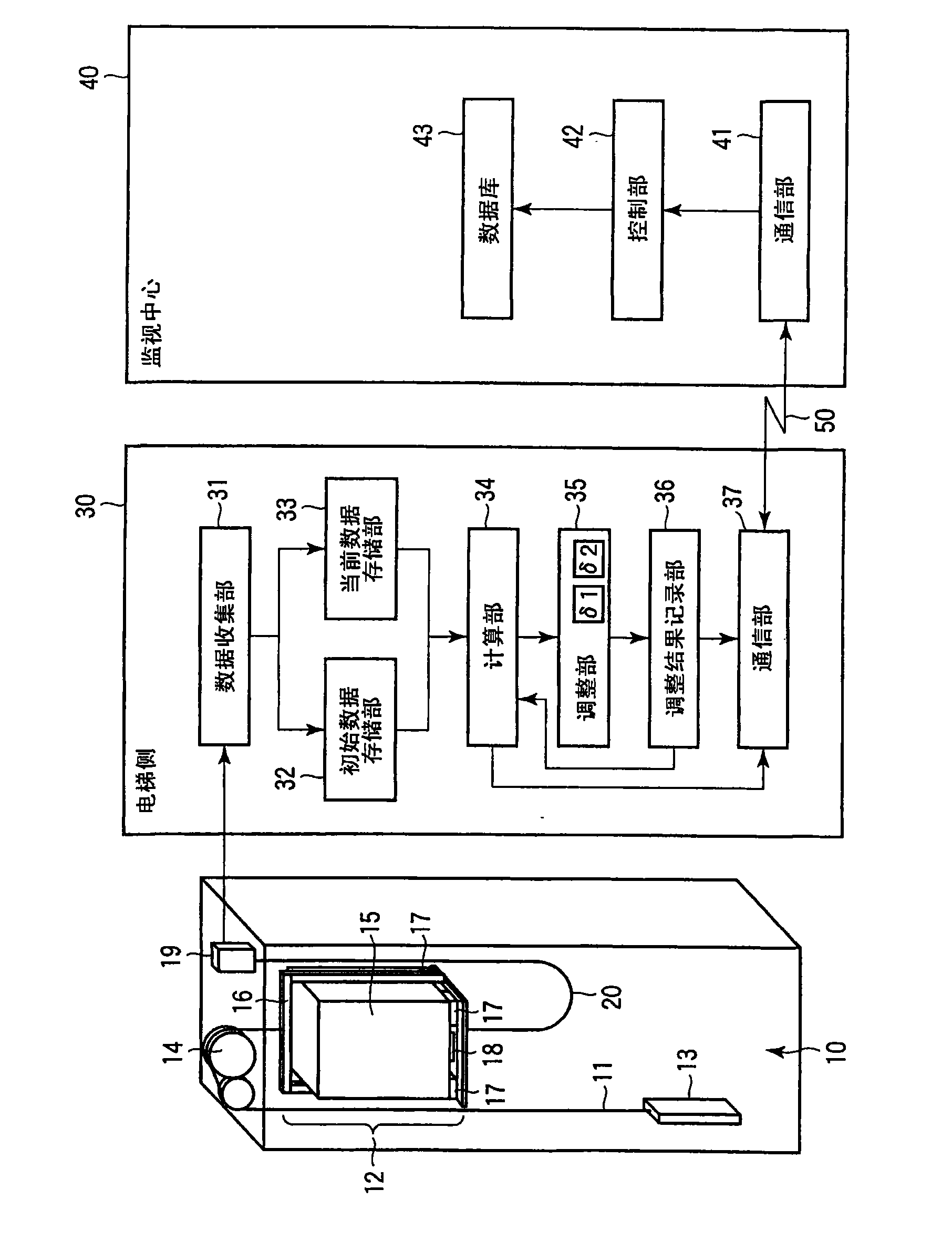

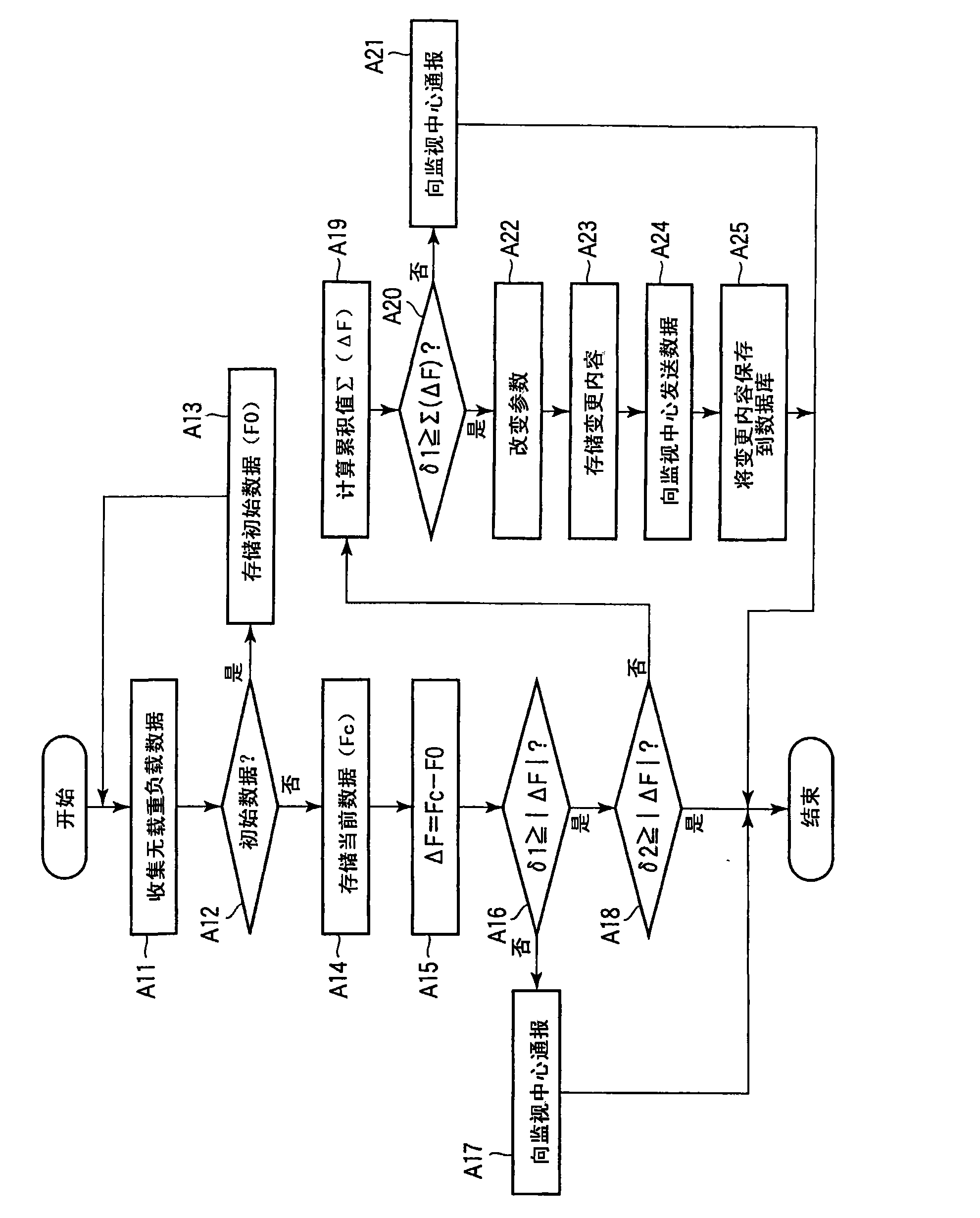

[0018] figure 1 It is a schematic diagram showing the structure of the elevator maintenance system according to the first embodiment of the present invention.

[0019] One end of the main rope 11 of the elevator 10 is connected to the car 12 , and the other end is connected to the counterweight 13 . When the hoist 14 is driven, the car 12 and the counterweight 13 run in a bucket type (つるベ type) in the hoistway through the main cable 11 wound on the sheave of the hoist 14 .

[0020] The car 12 is composed of a compartment 15 on which passengers ride, and a car frame 16 supporting the compartment 15 . The box chamber 15 is supported by the car frame 16 through the anti-vibration rubber 17 provided on the lower part thereof. A load gauge 18 connecting the box room 15 and the car frame 16 is installed on the bottom of the box room 15 . The load gauge 18 calculates the load load of the housing 15 based on the relative displacement between the housing 15 and the car frame 16 in t...

no. 2 example

[0055] Next, a second embodiment of the present invention will be described.

[0056] The configuration in the above first embodiment is to adjust the parameters through the change of the load data under the condition of no load. In contrast, in the second embodiment, parameter adjustment is performed based on load changes after the start of operation.

[0057] Figure 4 is a schematic diagram showing the configuration of the elevator maintenance system according to the second embodiment of the present invention. Also, for the drawings and the aforementioned first embodiment figure 1 The same components are denoted by the same symbols, and their descriptions are omitted here.

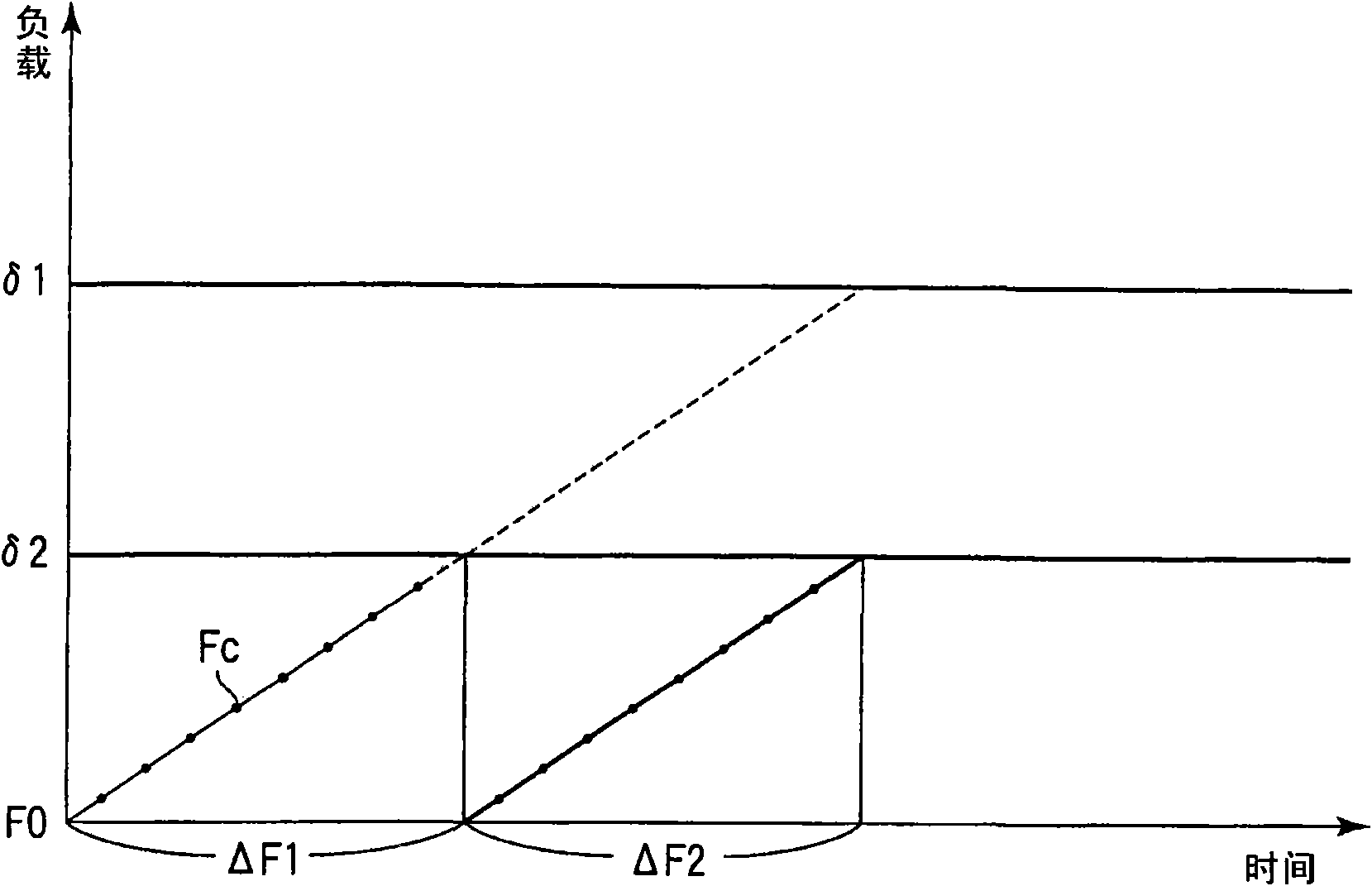

[0058] In the second embodiment, a load fluctuation storage unit 38 is added to the abnormality monitoring control device 30 . The load variation storage unit 38 stores the load variation Fr immediately after the operation is started. The adjustment unit 35 performs parameter adjustment when the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com