Resource-saving preparation method of isoolefine and conjugated diene copolymer

A conjugated diene and resource-saving technology is applied in the field of resource-saving preparation of isoolefin and conjugated diene copolymers, and can solve the problems of easy scaling, inability to provide low-temperature reaction solvents, and difficulty in promotion and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

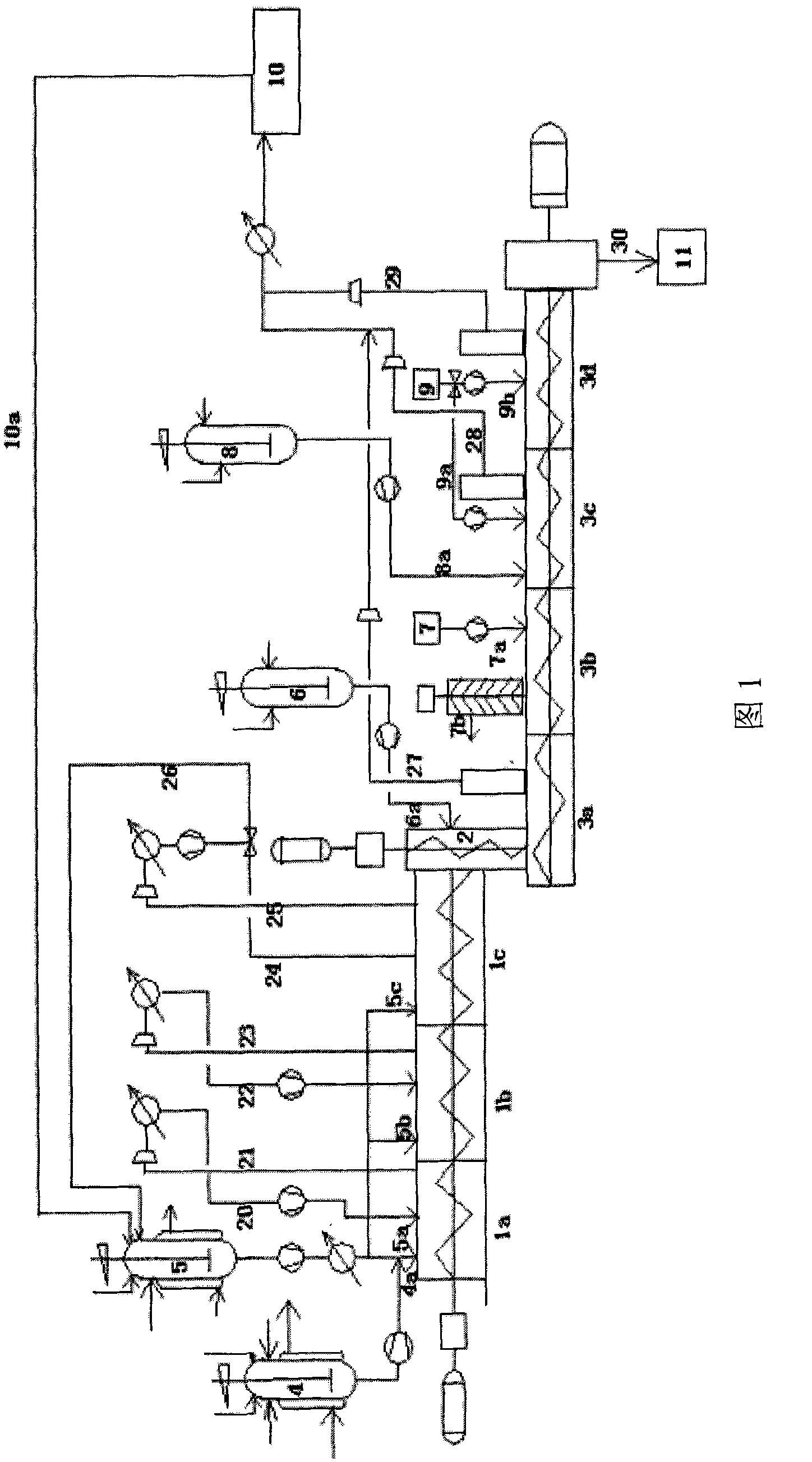

Image

Examples

Embodiment 1

[0063] 50% by mass of mixed monomer [containing 98.3% by mass of isobutylene and 1.7% by mass of isoprene] and 50% by mass of solvent (containing a mixed solvent of n-hexane and dichloromethane with a mass ratio of 70:30) were injected into the single The body is configured in the kettle 5, and the temperature is lowered to the polymerization temperature of -50°C by circulating a low-temperature (-70°C) cold medium. Then it is continuously transported to reactor 1 in sections through lines 5a, 5b and 5c. After a stable circulation flow is established at each section, the mass ratio of the mixed monomer solution added to the three sections is 1:1:1. Threaded elements ensure that individual streams can be separated.

[0064] Use 10 per mole (mixed) monomer -6 moles of diethylaluminum chloride (catalyst), 5×10 -7 moles of tert-butyl chloride (initiator), 10 -6 Moles of triethylamine (electron donor) and 1 liter of mixed solvent containing n-hexane and dichloromethane with a ma...

Embodiment 2

[0068] The present embodiment is the same as the preparation process and conditions of Example 1, and the difference is that the ingredients are formulated according to the following formula,

[0069] Inject 20% by mass of mixed monomer (containing 90% by mass of isobutylene and 10% by mass of isoprene) and 80% of solvent (containing a mixed solvent of butane and methyl chloride with a mass ratio of 80:20) into the monomer configuration Kettle 5 is fed into reactor 1 continuously at 3 points via lines 5a, 5b and 5c.

[0070] 10 per mole of monomer -7 moles of aluminum trichloride as catalyst, 10 -8 molar water as initiator, 10 -6 Moles of N, N-dimethylaniline as the electron donor and 1 liter of mixed solvent containing butane and methyl chloride with a mass ratio of 80:20 are continuously fed into the reactor 1 through the line 4a as the catalyst solution. The copolymerization reaction temperature is -100°C. The molecular weight (Mn) of the copolymer was 1.196 million / mol...

Embodiment 3

[0072] The present embodiment is the same as the preparation process and conditions of Example 1, and the difference is that the ingredients are formulated according to the following formula,

[0073] 40% by mass of mixed monomer (isoprene containing 98% of isobutylene and 2% by mass of mixed monomer) and 60% of solvent (containing a mixed solvent of n-hexane and dichloromethane with a mass ratio of 60:40) At the same time, it is continuously conveyed to reactor 1 via lines 5a, 5b and 5c.

[0074] 3×10 per mole of monomer -5 mol of dichloroethylaluminum catalyst, 2×10 -6 moles of tert-butyl acetate as initiator, 6×10 -5 Moles of 2,6-di-tert-butylpyridine as the electron donor and 1 liter of mixed solvent containing n-hexane and dichloromethane with a mass ratio of 60:40 as the catalyst solution were continuously fed into the reactor 1 through the line 4a.

[0075] The copolymerization reaction temperature was -60°C. The molecular weight (Mn) of the copolymer was 308,000 / mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com