Multi-sectorization shallow junction low-temperature semiconductor structure with differ doping concentration and high disruptive voltage as well as manufacturing method thereof

A technology with high breakdown voltage and doping concentration, applied in semiconductor devices, electric solid devices, circuits, etc., can solve the problems of complex design, incompatibility, thick dielectric thickness, etc., reduce complexity and difficulty, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention is not limited to the semiconductor device described below, but also other semiconductor devices that can improve the breakdown voltage by adopting various similar methods that can meet the structural requirements according to the structural core and design spirit of this method.

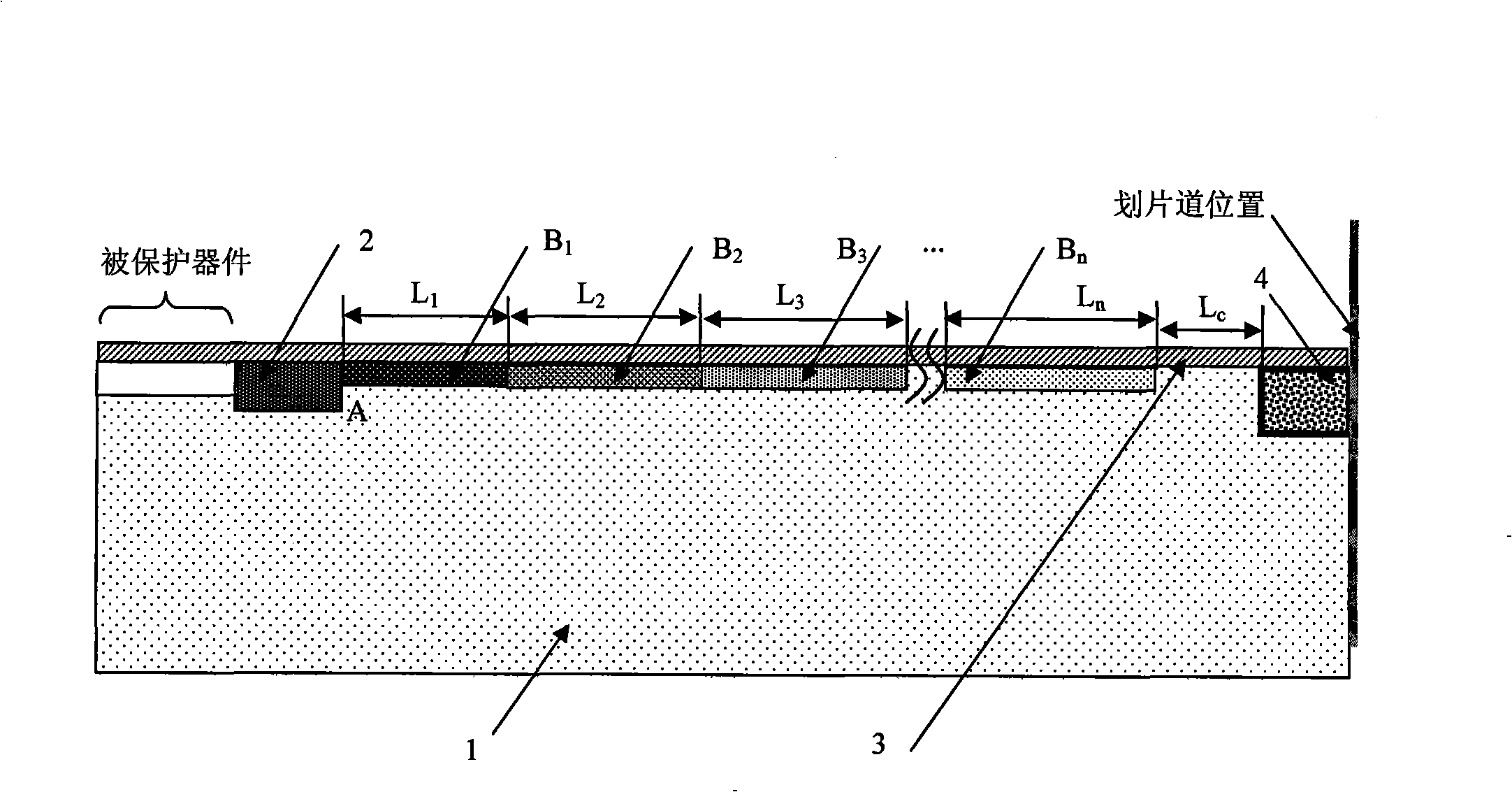

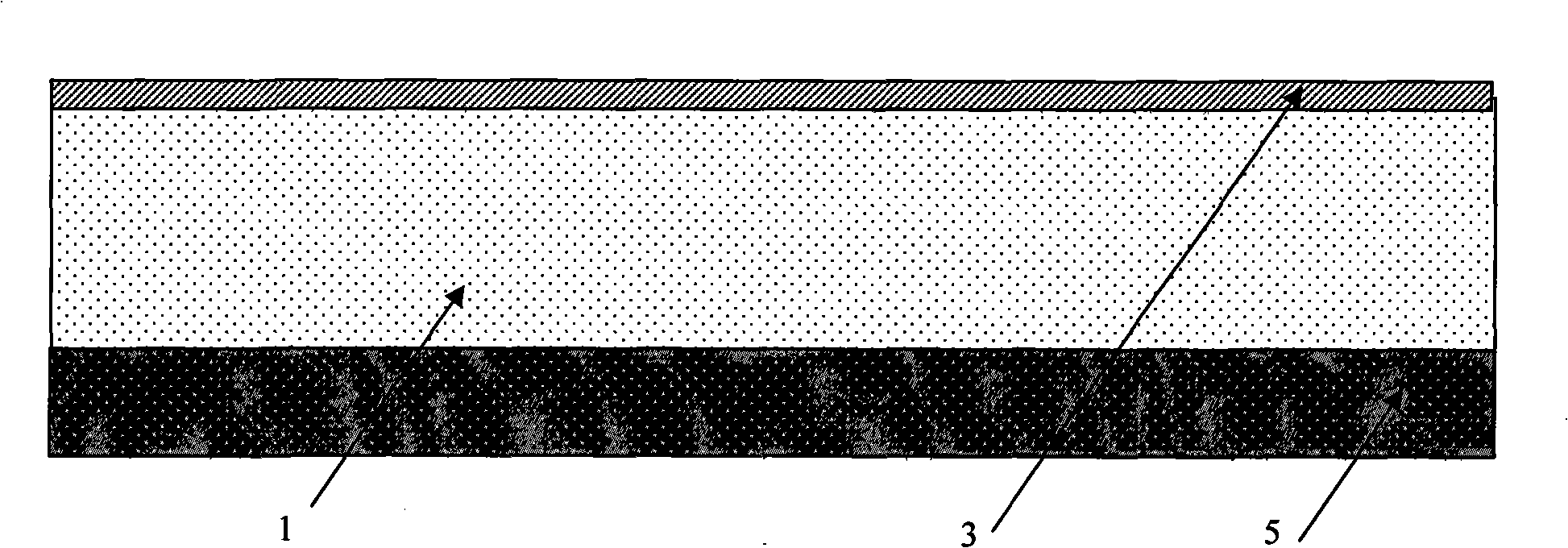

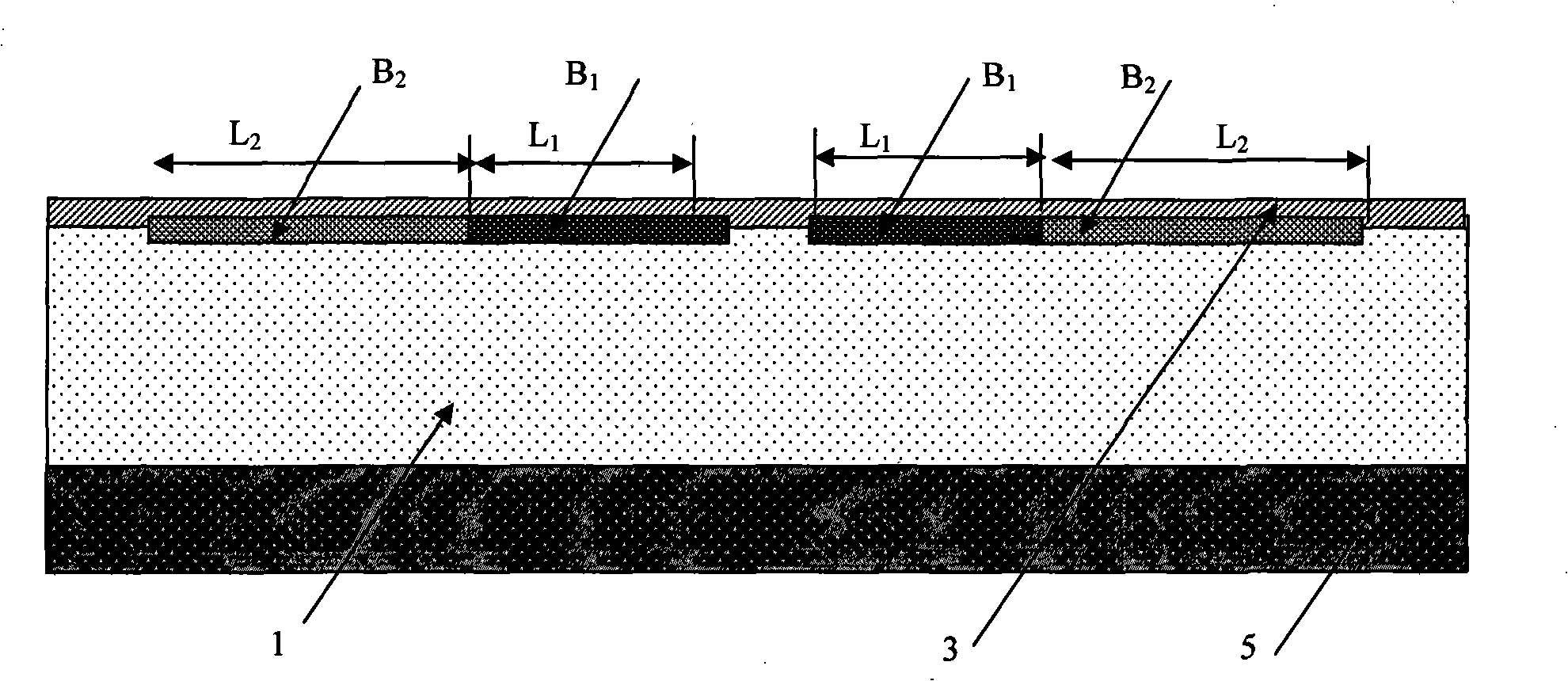

[0029] The main structure of the junction termination technology proposed by this method is as follows: figure 1 As shown, its structure includes semiconductor material 1, main diffusion junction 2, partition withstand voltage layer B 1 、B 2 、B 3 until B n (where n≥2) and the depletion termination region 4 and the dielectric layer 3 . figure 1 It also schematically shows the "protected device" in the upper left corner and the "scribing lane position" on the right side of the figure. Generally, the junction termination of the protected device is symmetrical, and figure 1 Take the symmetric structure of the junction terminal section on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com