Colorful filter manufacture method and device

A technology of color filter and manufacturing method, which is applied in the direction of copying/marking method, optics, optical components, etc., can solve the problems of bulky, slow equipment speed, small format, etc., to improve process efficiency, improve production efficiency, process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

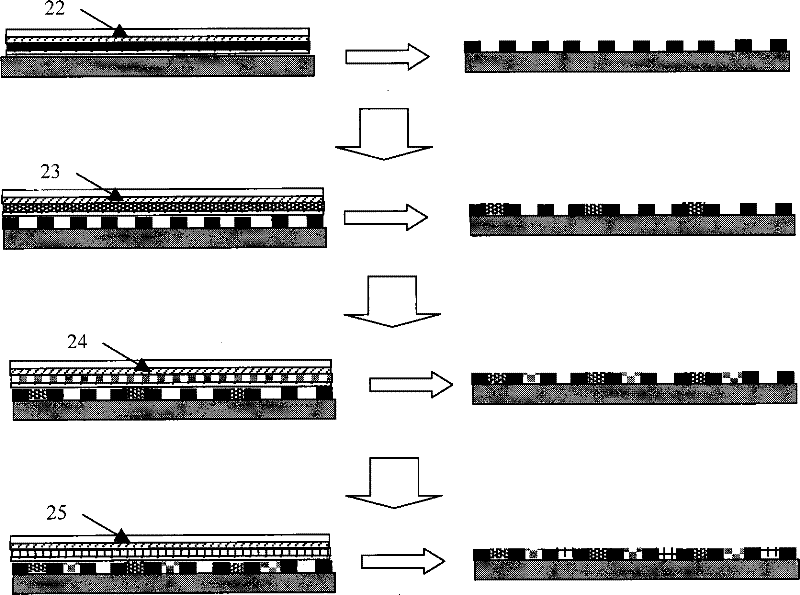

[0051] 1. Make black, red R, green G and blue B thermal transfer films.

[0052] Its production process is as follows:

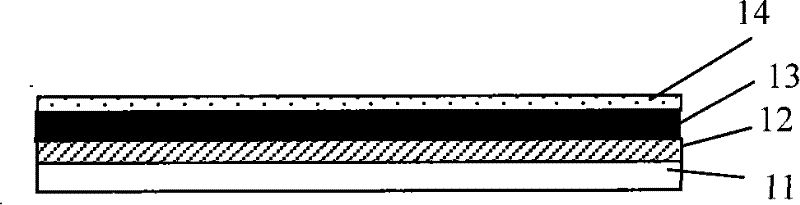

[0053] (1) See attached figure 1 As shown, the release layer 12 is coated on the PET plastic substrate 11, and the thickness of the PET plastic substrate is 10um-150um;

[0054] (2) Coating black resin on the surface of the release layer, or coating resin permeated with colored dyes on the release layer, the colors of the dyes are respectively red, green and blue to form a color layer (13). The chromaticity of the color layer meets the color filter standard, and the thickness meets the thickness requirements of each color pixel of the color filter. The thickness of each color layer is <3um.

[0055] (3) Coating a layer of adhesive layer 14 on the color layer, such as transparent hot melt adhesive, the specific material should be selected according to the adhesion requirements of the material of the color filter substrate. According to the above steps, a ...

Embodiment 2

[0063] Embodiment two: see attached Figure 8 Shown, a kind of planar type color filter manufacturing device comprises by DPSSL laser light source 51 with TTL signal interface, iris diaphragm 52, spot shaper 53, quartz lens 55 (objective lens), reflecting mirror 56 and quartz lens 57 together form a 4F system, a beam splitting device 58 (the example in this figure is a beam splitting into a rectangular light spot with uniform light intensity in one-dimensional and three-beam spots), a working platform 591 , and a control system 510 .

Embodiment 3

[0064] Embodiment three: see attached Figure 9 Shown, a kind of planar type color filter manufacturing device comprises by DPSSL laser light source 51 with TTL signal interface, iris diaphragm 52, spot shaper 53, quartz lens 55 (objective lens), reflecting mirror 56 and quartz lens 57 together form a 4F system, a beam splitter 58 (the example in this figure shows that the beam is split into a rectangular light spot with uniform light intensity in one-dimensional and three-beam spots), a drum-type workbench 592 , and a control system 510 .

[0065] In this embodiment, the energy distribution of the light beam emitted by the laser is 541, which is Gaussian. After the beam is shaped, the energy distribution of the beam is 542, which is rectangular, and the light intensity is uniform.

[0066] In this embodiment, the beam splitting element can be a beam splitting grating or a beam shaping device (LCD or DMD), which divides the single beam emitted by the laser into multiple one-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com