Ink composition and oxygen indicator

A technology of composition and polymer materials, which is applied in the direction of material analysis by observing the influence on chemical indicators, ink, analysis using chemical indicators, etc., which can solve the problems of poor light resistance of oxygen indicators and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

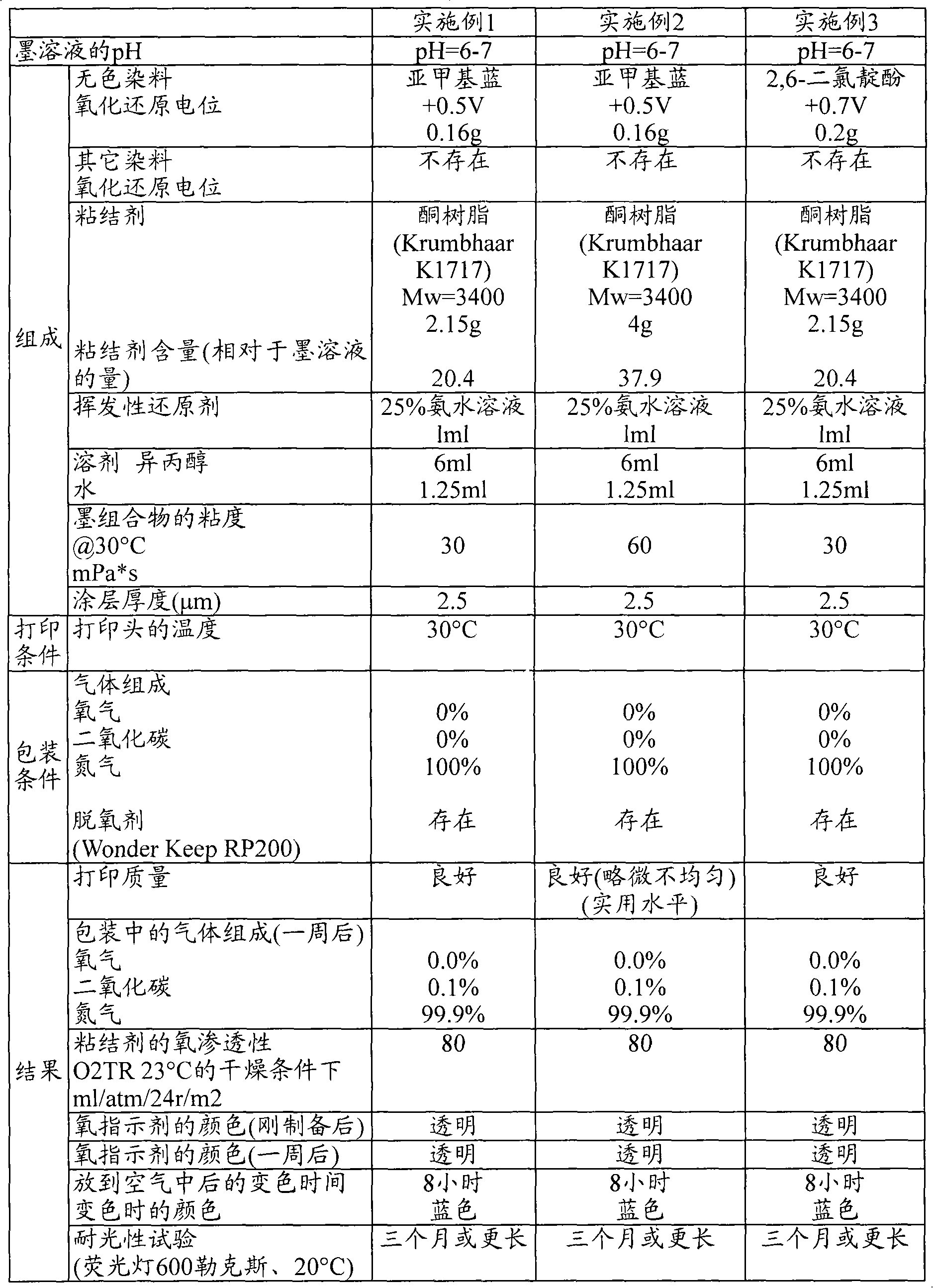

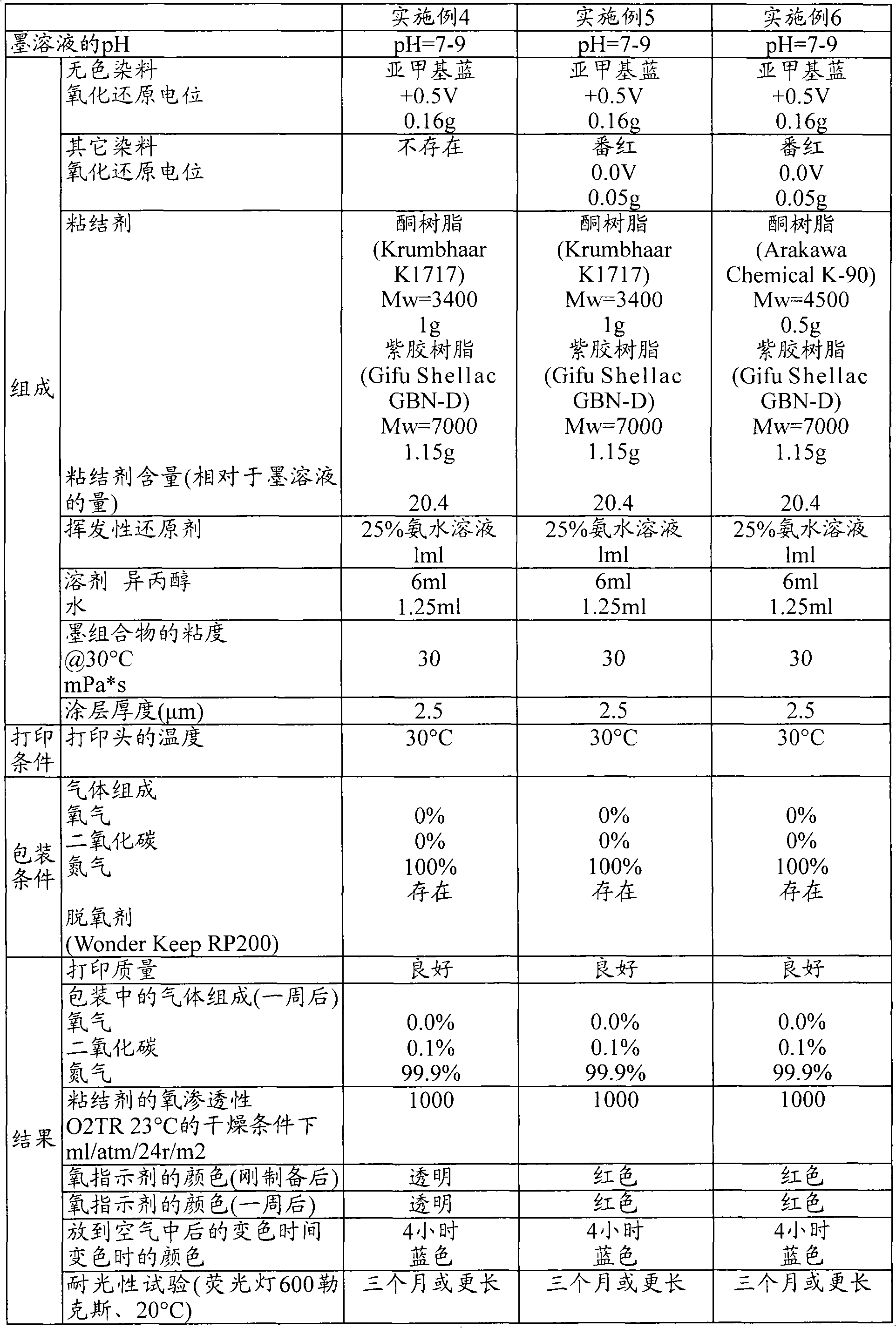

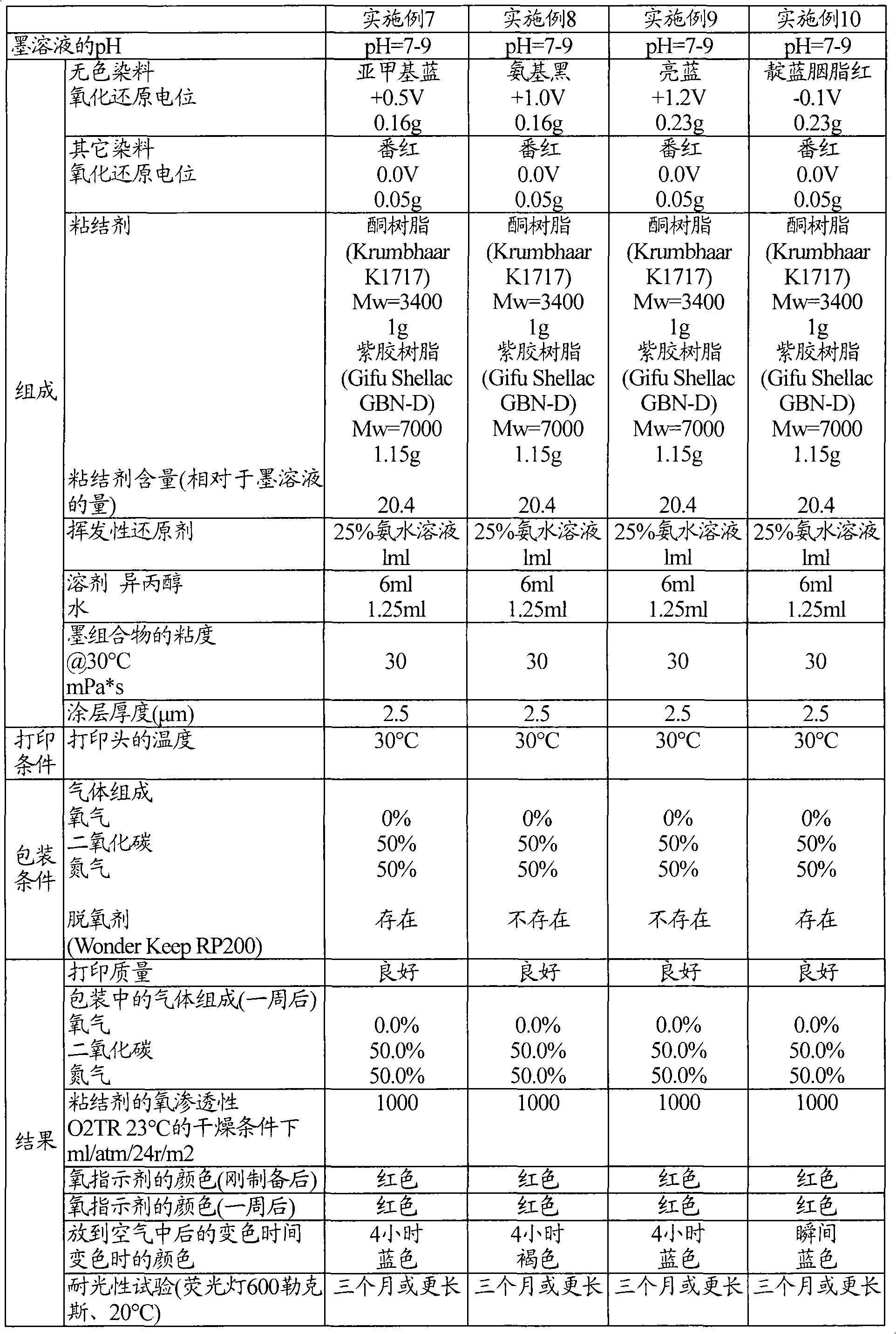

Embodiment 1 to 11

[0082] The ink composition prepared by the above method with the components described in Table 1 was placed in the ink tank of an inkjet printer manufactured by SPECTRA INC., and the temperature of the print head of the printer was raised to 30° C. The PE surface (corona treated surface) of the inner surface of the top sealing film is printed, the printed film is used as the top sealing film, the inside of the container is directly emptied, and the vacuum inflation packaging machine DYNAPACK 462 is used to inflate the packaging Heat seal to prepare an airtight package. The ink compositions and preparation conditions of the samples are described in Table 1. Examples 1 to 10 were good in print quality and light fastness. Example 11 has a higher viscosity and thus is slightly uneven in the evaluation of inkjet printing, although it does not cause a problem from a practical point of view. In Example 11, the pH of the ink solution was 10 to 11, so it tended to fade within a week ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com