Forward slip type hydraulic support

A hydraulic support and front-end technology, which is applied to mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of limited popularization and application, high price, and strict geological conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

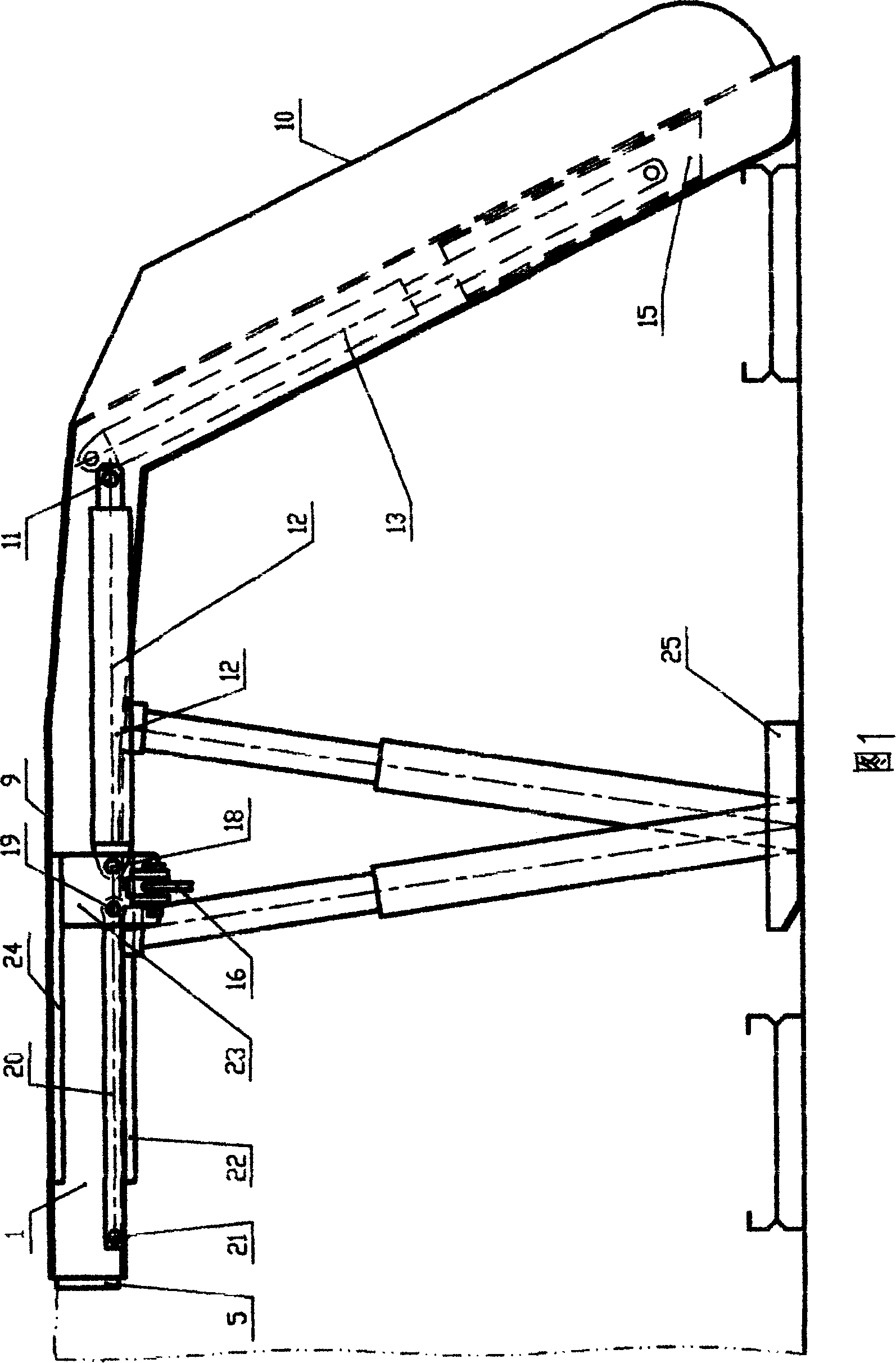

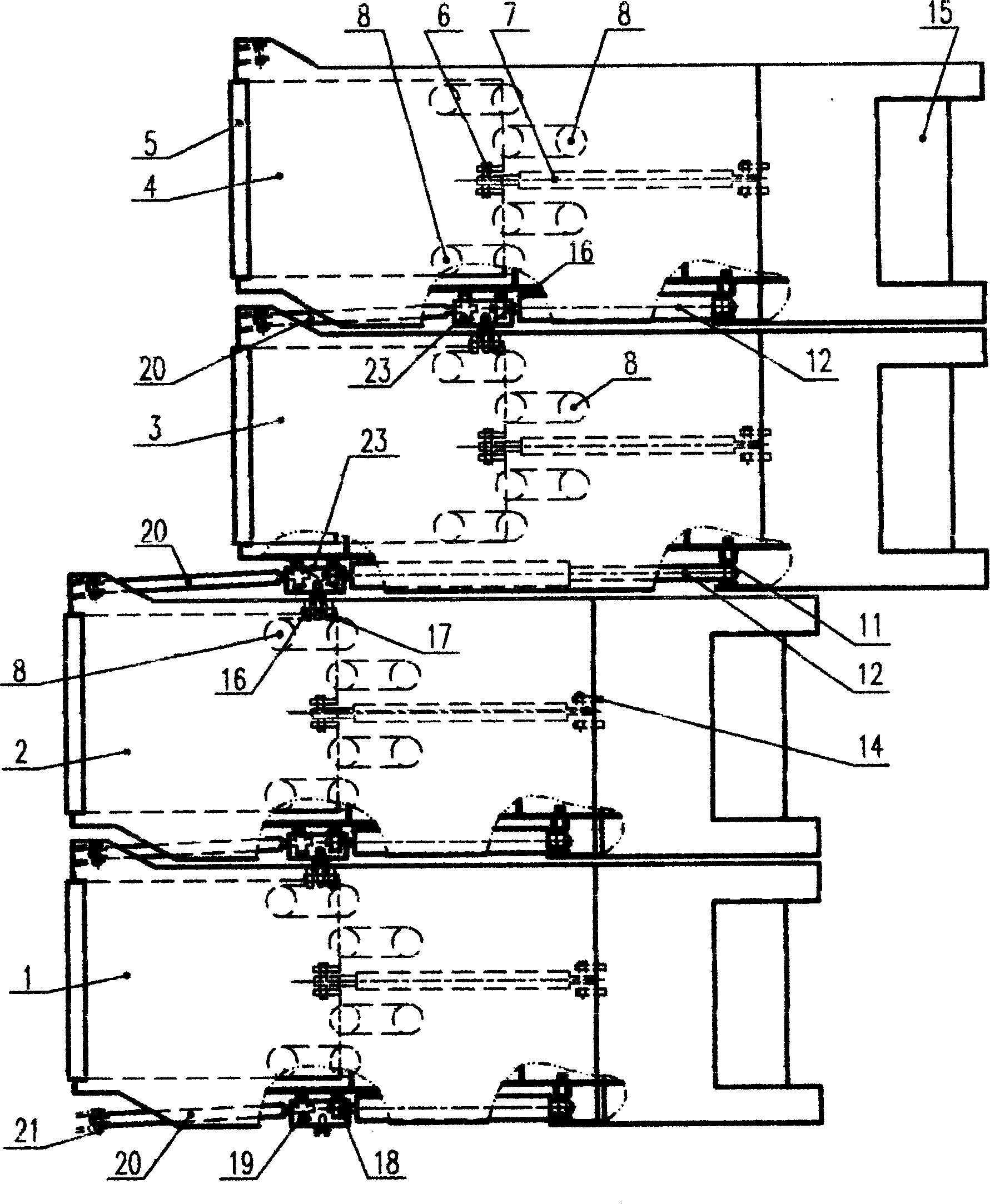

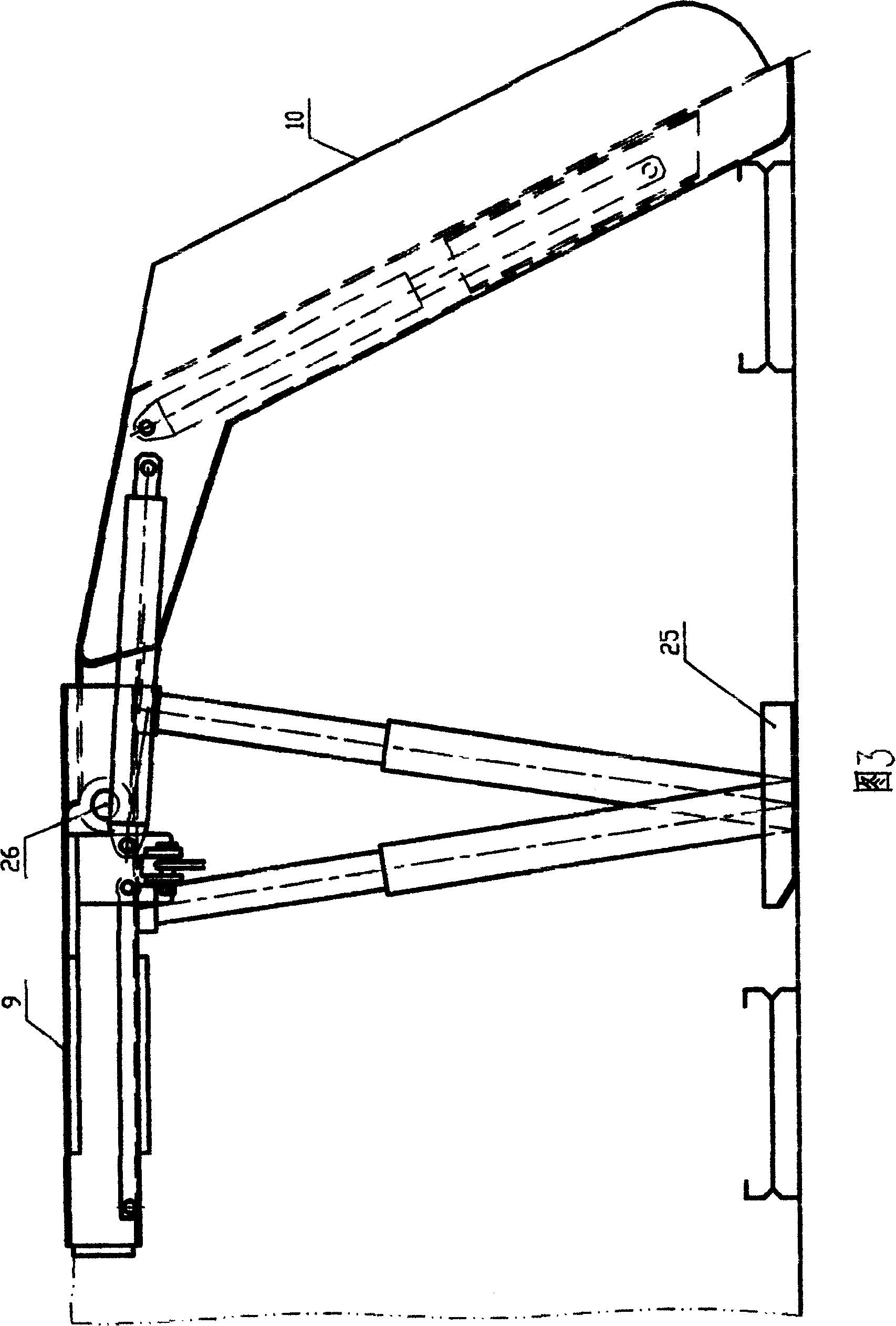

[0020] Combining Figure 1 and figure 2 , the first embodiment of the front sliding hydraulic support of the present invention includes an integrated top beam 1 whose front section is parallel to the top plate and the rear section is obliquely downward and in contact with the bottom plate; The slider 23 that slides on the lower guide rail 22 and the upper guide rail 24; one end is connected to the top beam through a pin 17, and the other end is connected to the connecting piece 16 connected to the slider 23 that slides on the top beam; the hydraulic prop 8 supported under the top beam; The chassis 25 connected to the lower end of the hydraulic prop 8; one end is hinged with the top beam through the pin 11, and the frame moving cylinder 12 is hinged at the other end with the slider 23 through the pin 18; The force transmission member 20 hinged with the front end of the top beam of the adjacent frame; the front extension beam oil cylinder 7 and the front extension beam 5 hinged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com