Microwave non-polar ultraviolet light catalyzing integrated reaction device

An electrodeless ultraviolet light and reaction device technology, which is applied in illumination water/sewage treatment, oxidized water/sewage treatment, chemical/physical/physical-chemical process of applying energy, etc., can solve the problem of high energy consumption, microwave and ultraviolet light utilization rate Low energy consumption, high utilization rate, and temperature controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

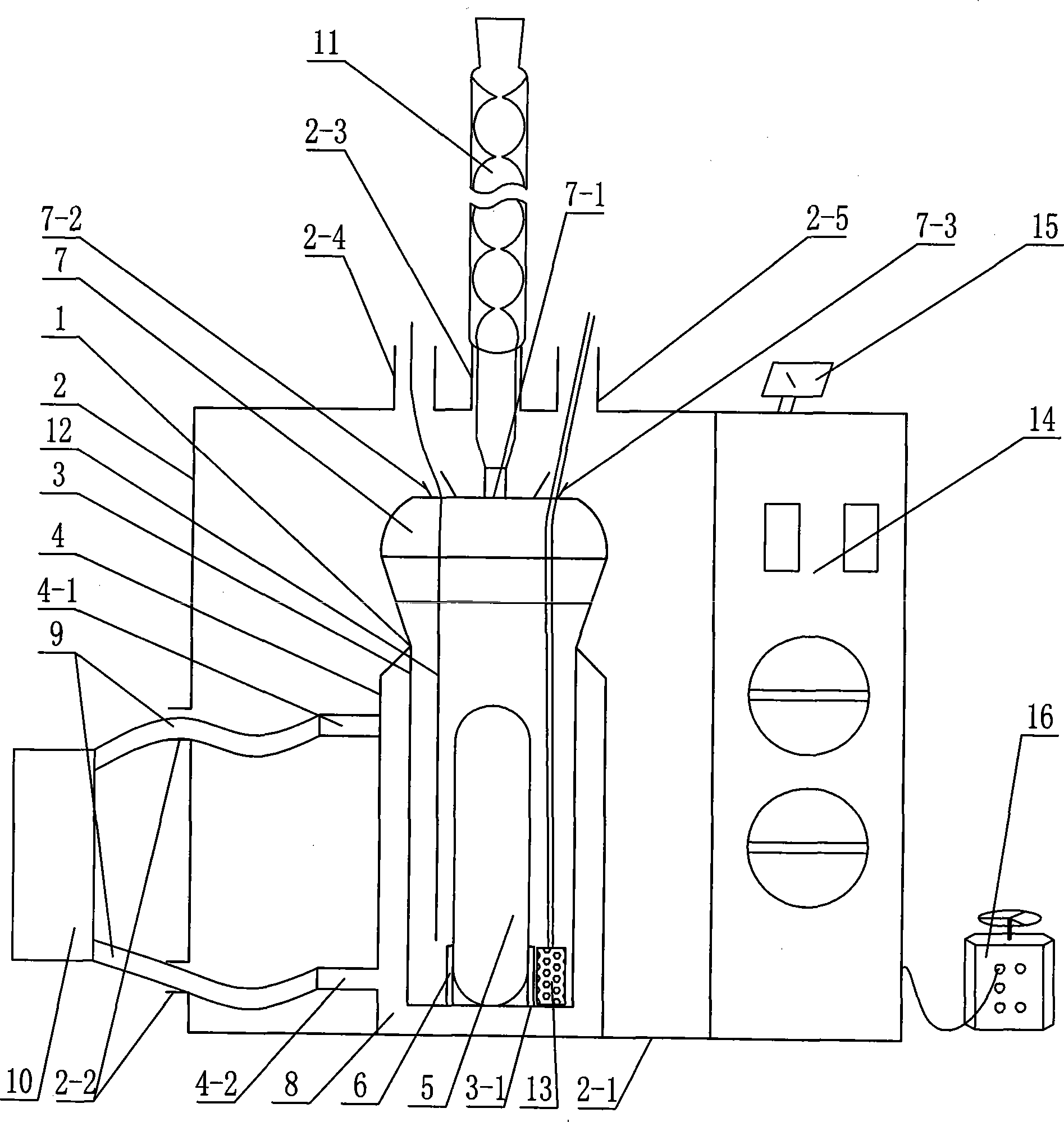

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is made up of double-layer reactor 1 and microwave chemical experiment instrument 2, described double-layer reactor 1 is made up of reaction chamber 3, circulating cooling jacket 4, electrodeless ultraviolet lamp 5, lamp holder 6, reaction chamber The chamber cover plate 7, two connecting pipes 9 and an external peristaltic pump 10, the circulating cooling jacket 4 and the reaction chamber 3 are fired as one, and the circulating cooling water is formed between the circulating cooling jacket 4 and the reaction chamber 3 chamber 8, the pipe wall of the circulating cooling jacket 4 is provided with an outlet pipe 4-1 and a water inlet pipe 4-2 from top to bottom, and a lamp holder 6 is fixed on the bottom plate 3-1 of the reaction chamber 3, The electrodeless ultraviolet lamp 5 is installed on the lamp holder 6, the upper end surface of the reaction chamber 3 is buckled with a reac...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the reaction chamber 3 , the circulating cooling jacket 4 and the reaction chamber cover 7 in this embodiment are all made of glass material, which is conducive to the transmission of microwaves. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The lamp socket 6 of the present embodiment is made of a glass sand core material. Such setting can prevent the reaction system from bumping. Other compositions and connections are the same as in the first embodiment.

[0010] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the lamp holder 6 of this embodiment is fixedly installed at the center of the bottom plate 3 - 1 of the reaction chamber 3 , and the electrodeless ultraviolet lamp 5 is vertically installed on the lamp holder 6 . Such an arrangement keeps the ultraviolet light radiated in parallel from the center of the reaction chamber, and more effectively improves the utilization efficiency of light. Other compositions and connections are the same as in the first embodiment.

[0011] Specific implementation mode five: combination figure 1 Describe this embodiment, the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com