Engaging and disengaging gear for washing machine deceleration clutch and washing machine deceleration clutch thereof

A deceleration clutch and clutch device technology, applied in washing devices, other washing machines, transmission devices, etc., can solve the problems of complex structure of clutch sleeve, large vibration and impact force, affecting service life, etc., to solve early wear problems and improve wear life , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

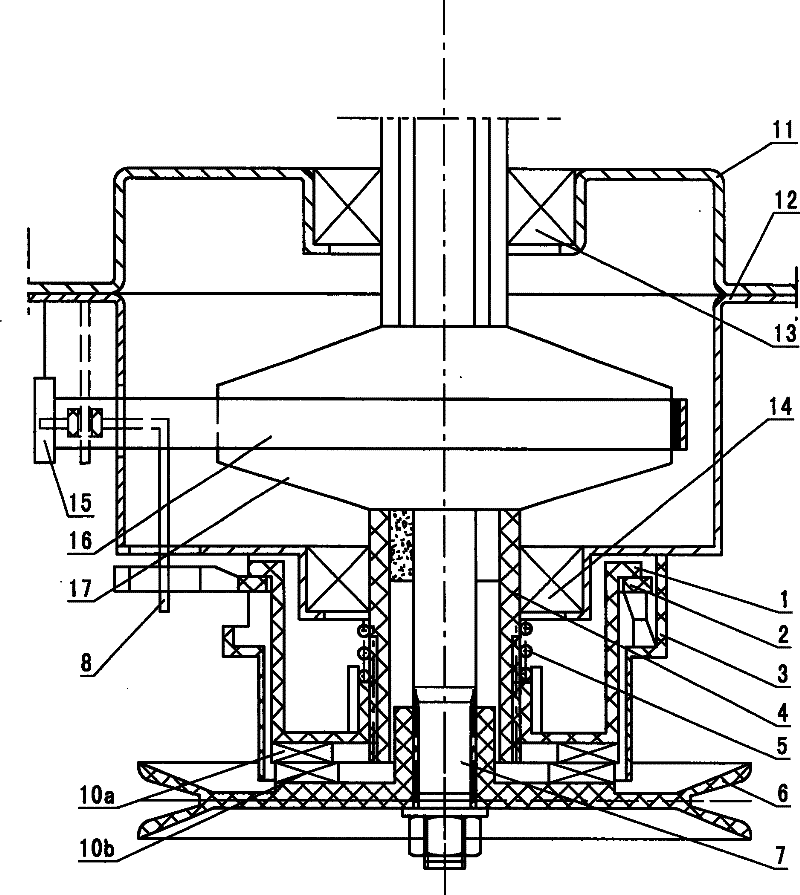

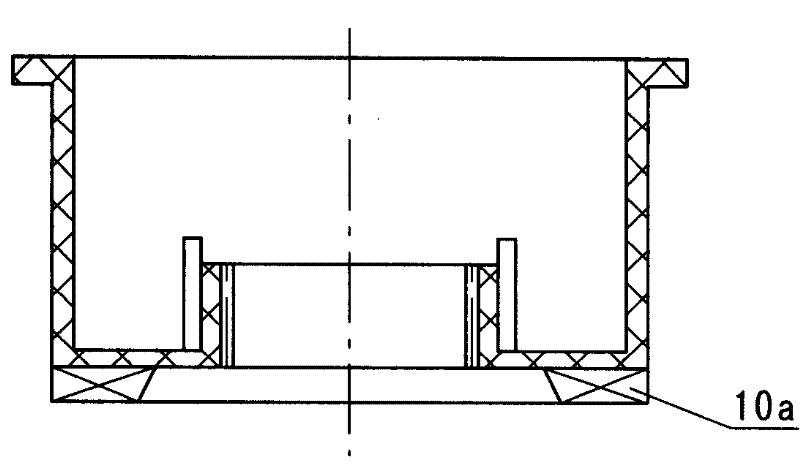

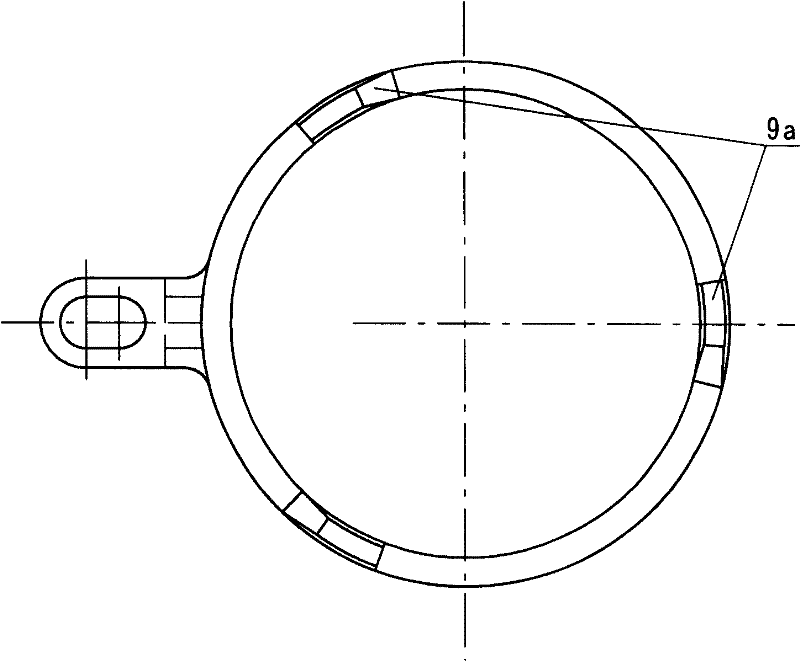

[0030] combine figure 1 , a deceleration clutch clutch device for a washing machine, which is mainly composed of a clutch sleeve 1, a dial ring 2, a fixed sleeve 3, a spring 5, a finger 8, a lower shaft sleeve 4, an input shaft 7 and a pulley 6, and the pulley 6 is installed on the input shaft 7, the pulley 6 and the clutch sleeve 1 can be meshed through the corresponding set of clutch teeth 10b, 10a, the clutch sleeve 1 is set on the outer circle of the lower shaft sleeve 4, and can slide axially, the spring 5 is installed on the clutch sleeve 1, the clutch A dial ring 2 and a fixed sleeve 3 which allow the clutch sleeve 1 to move axially are installed outside the sleeve 1, the dial ring 2 is located between the clutch sleeve 1 and the fixed sleeve 3, and the dial ring 2 is connected with the claw 8. refer to Figure 3A , Figure 3B , Figure 4A , Figure 4B , The fixed sleeve 3 and the dial ring 2 are correspondingly provided with clutch blocks 9b, 9a provided with incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com