Method for extracting high pure chicoric acid from Coneflower

A kind of Echinacea purpurea, high-purity technology, applied in the direction of pharmaceutical formulations, separation/purification of carboxylic acid esters, medical preparations containing active ingredients, etc., can solve problems such as the inability to realize large-scale industrial production, and achieve high purity and high yield High, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Ethanol extraction: Take 100 g of crushed dry Echinacea purpurea root, add 3-15 times the amount of 95% ethanol solvent, soak at room temperature for 24 hours, heat and reflux for 3 hours, and separate the medicinal liquid. Add 95% ethanol with 10 times the amount of medicinal dregs, heat and reflux for 2 hours, and separate the medicinal liquid. The extracted medicinal liquids are combined, and the impurities in the extraction liquid are removed by means of filtration and centrifugation. The extraction solvent is recovered by distillation or vacuum distillation to obtain the ethanol extract of Echinacea purpurea.

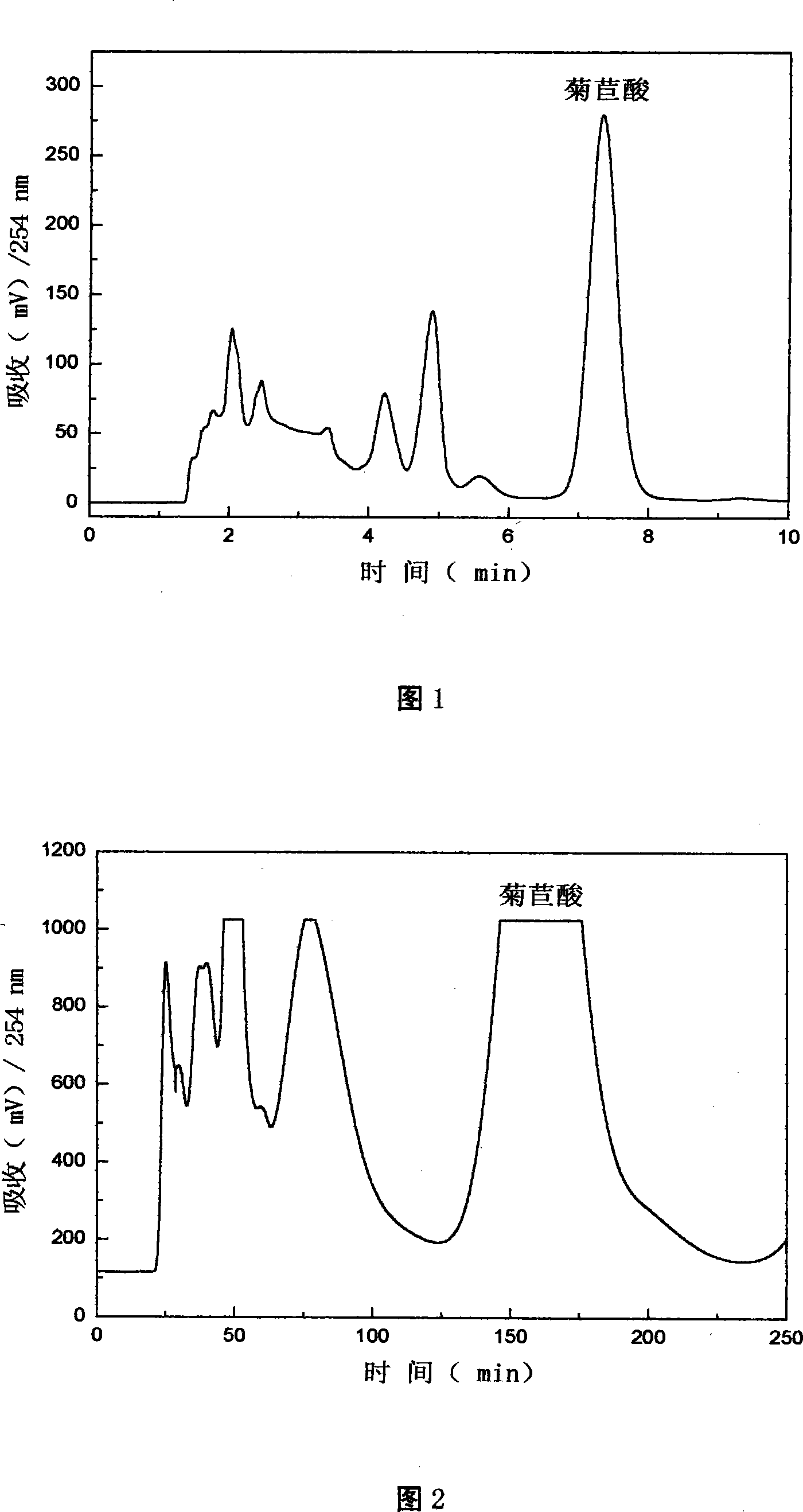

[0022] Macroporous adsorption resin column pre-separation: put the ethanol extract obtained above on an AB-8 macroporous adsorption resin column, first wash with water until the effluent is colorless, then elute with 5% ethanol 10 times the column volume, collect 70% ethanol eluate, the solvent was recovered by distillation under reduced pressure, and th...

Embodiment 2

[0025] Take 100 g of crushed Echinacea purpurea roots, add 1.5 L of 40% ethanol, soak at room temperature for 4 hours, heat and reflux for 3 hours, and separate the medicinal liquid. Add 1 L of 95% ethanol, heat to reflux for 2 hours, and separate the liquid medicine. The extracted medicinal liquids are combined, and the impurities in the extraction liquid are removed by filtering. The extraction solvent is recovered by vacuum distillation to obtain the ethanol extract of Echinacea purpurea.

[0026] Put the ethanol extract obtained above on the AB-8 macroporous adsorption resin column, first wash with water until the effluent is colorless, then elute with 30% ethanol of 10 times the column volume, collect the 30% ethanol eluate, reduce The solvent is recovered by pressure distillation to obtain the cichoric acid extract.

[0027] Use petroleum ether-ethyl acetate-methanol-acetic acid water as the high-speed countercurrent chromatography two-phase solvent system to separate ...

Embodiment 3

[0033] Take 100 g of crushed Echinacea purpurea roots, add 1.5 L of 40% ethanol, soak at room temperature for 4 hours, heat and reflux for 3 hours, and separate the medicinal liquid. Add 1 L of 95% ethanol, heat to reflux for 2 hours, and separate the liquid medicine. The extracted medicinal liquids are combined, and the impurities in the extraction liquid are removed by filtering. The extraction solvent is recovered by vacuum distillation to obtain the ethanol extract of Echinacea purpurea.

[0034] Put the ethanol extract obtained above on the AB-8 macroporous adsorption resin column, first wash with water until the effluent is colorless, then elute with 30% ethanol of 10 times the column volume, collect the 30% ethanol eluate, reduce The solvent is recovered by pressure distillation to obtain the cichoric acid extract. The purity of the prepared cichoric acid can reach more than 99%, and the yield can reach more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com