Pressure steam sterilizer dynamic pulse type gas exhausting method

A pressure steam, dynamic pulse technology, applied in sanitary equipment, water supply devices, heating and other directions for toilets, can solve problems such as reducing the latent heat of steam, affecting the sterilization effect, affecting the steam saturation, etc., and achieves good steam penetration and improvement. The effect of the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] For the application on the lower exhaust type sterilizer, after the water injection is completed, before the cavity temperature reaches the local boiling point temperature, the exhaust valve is kept open, and the exhaust valve is closed after reaching the boiling point temperature.

[0022] Open the steam inlet valve to enter the steam, when the temperature of the sterilizer cavity reaches the set opening point, close the exhaust valve to suspend the exhaust and continue to enter the steam to increase the temperature and pressure. When the cavity temperature reaches the set upper limit value, close the steam inlet valve, open the exhaust valve, and reduce the temperature and pressure of the cavity; when the cavity temperature reaches the set lower limit value closing point, close the exhaust valve, open Inlet valve, and then continue to heat up. Repeatedly performing positive pressure exhaust for 2-4 times in this way, on the one hand, it can control the time point of s...

Embodiment 2

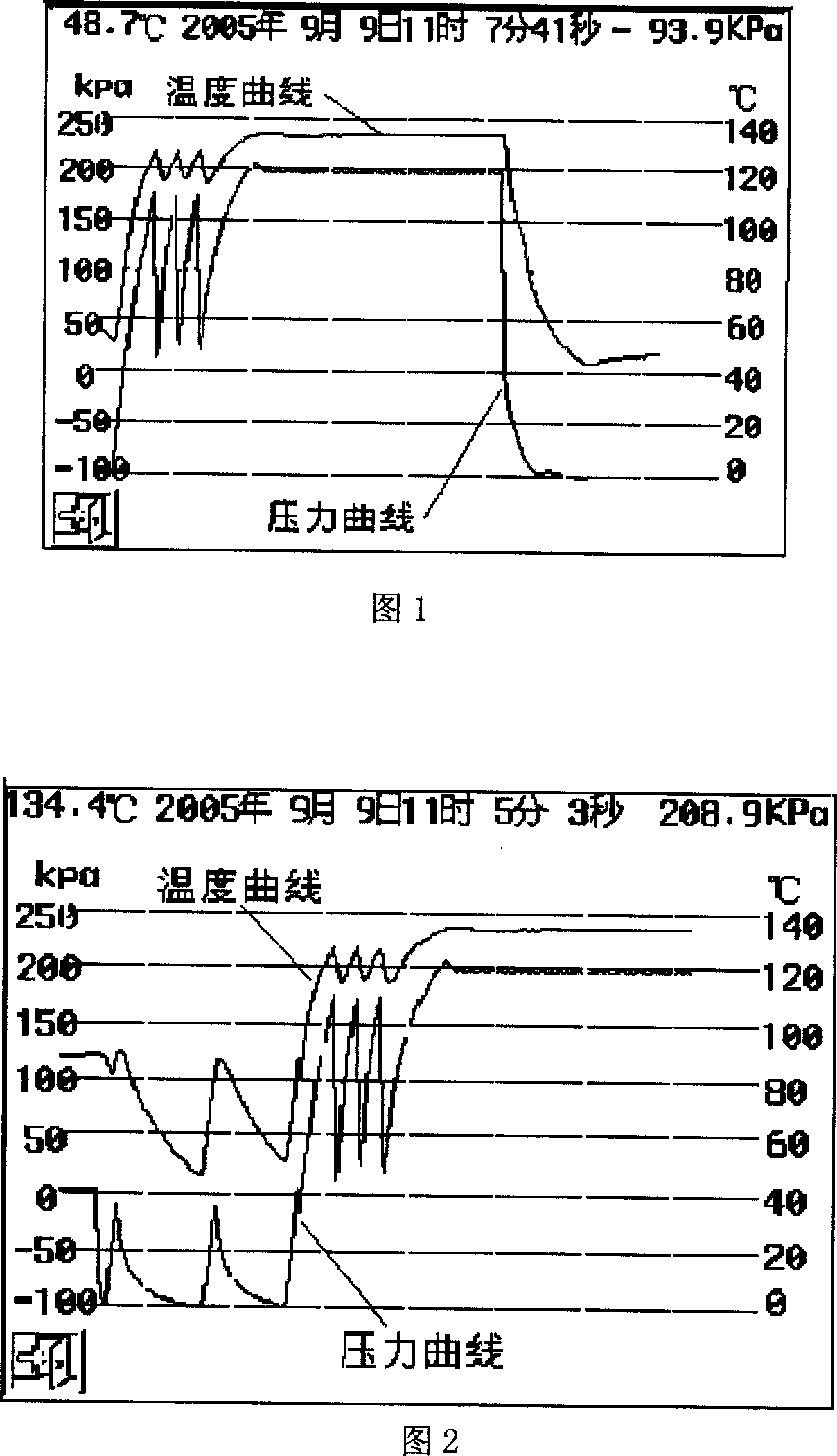

[0032] As shown in Figure 1, for the application on the pre-vacuum sterilizer, draw a deep vacuum first. The vacuum can be set to -70Kpa (corresponding to an absolute pressure of 30Kpa).

[0033] Then open the steam inlet valve to feed steam into the sterilizer cavity to raise the temperature. When the pressure rises to a settable upper limit of the pressure point between 100-200Kpa (corresponding to the absolute pressure of 200-300Kpa), the exhaust valve is opened to exhaust steam. When the exhaust reaches a lower limit of the pressure point that can be set between 10-100KPa (corresponding to the absolute pressure of 110-200Kpa), close the exhaust valve. Inject steam into the cavity again. The chamber pressure rises accordingly. When the pressure rises to the upper limit of the set pressure point, the exhaust will be carried out. Repeat this cycle 3 times.

[0034] After the exhaust process is over, continue to enter the steam to raise the temperature until it enters the...

Embodiment 3

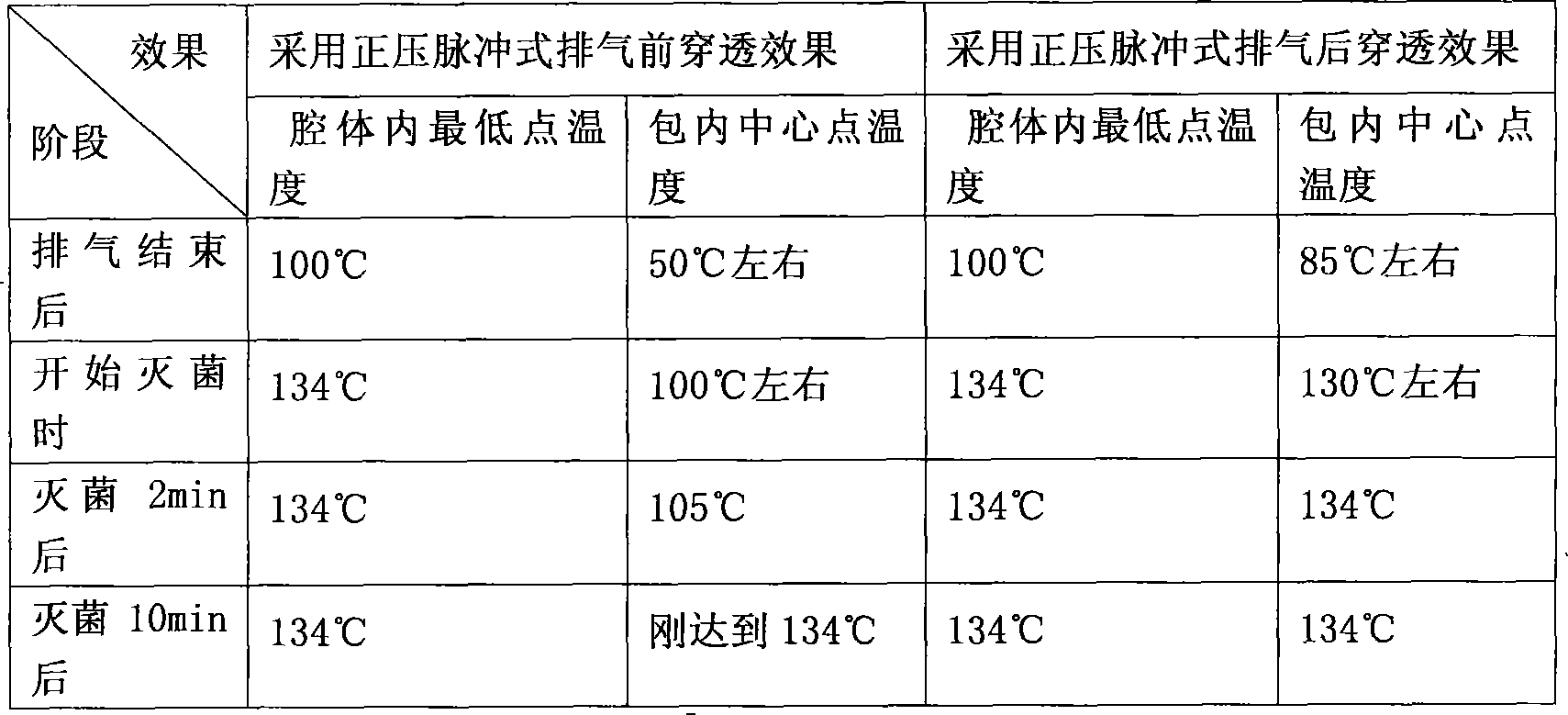

[0036] As shown in Figure 2, the application of the dynamic pulse exhaust method on the pulsating vacuum sterilizer requires three pulsating vacuuming processes. The upper limit and lower limit of pulsating vacuum setting are respectively set to 60Kpa (corresponding to 160Kpa under absolute pressure) and -80Kpa (corresponding to 20Kpa under absolute pressure). Then steam is fed into the cavity of the pulse vacuum sterilizer to raise the temperature. When the chamber pressure rises to a settable upper limit of the pressure point (such as 180Kpa) between 100-200Kpa (corresponding to an absolute pressure of 200-300Kpa), exhaust steam. Exhaust steam, and close the exhaust valve when the pressure in the cavity drops to a settable lower limit of the pressure point (such as 30Kpa) between 10-100KPa (corresponding to the absolute pressure of 110-200Kpa). Inject steam into the chamber again. The chamber pressure rises accordingly. When the pressure rises to the upper limit of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com