Gril capable of putting top coal

A gangue retaining device and top coal caving technology, which is applied in the direction of supporting the top beam of the mine roof, mining equipment, earthwork drilling, etc., can solve the problems of bulkiness, large tail beam gap, instability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

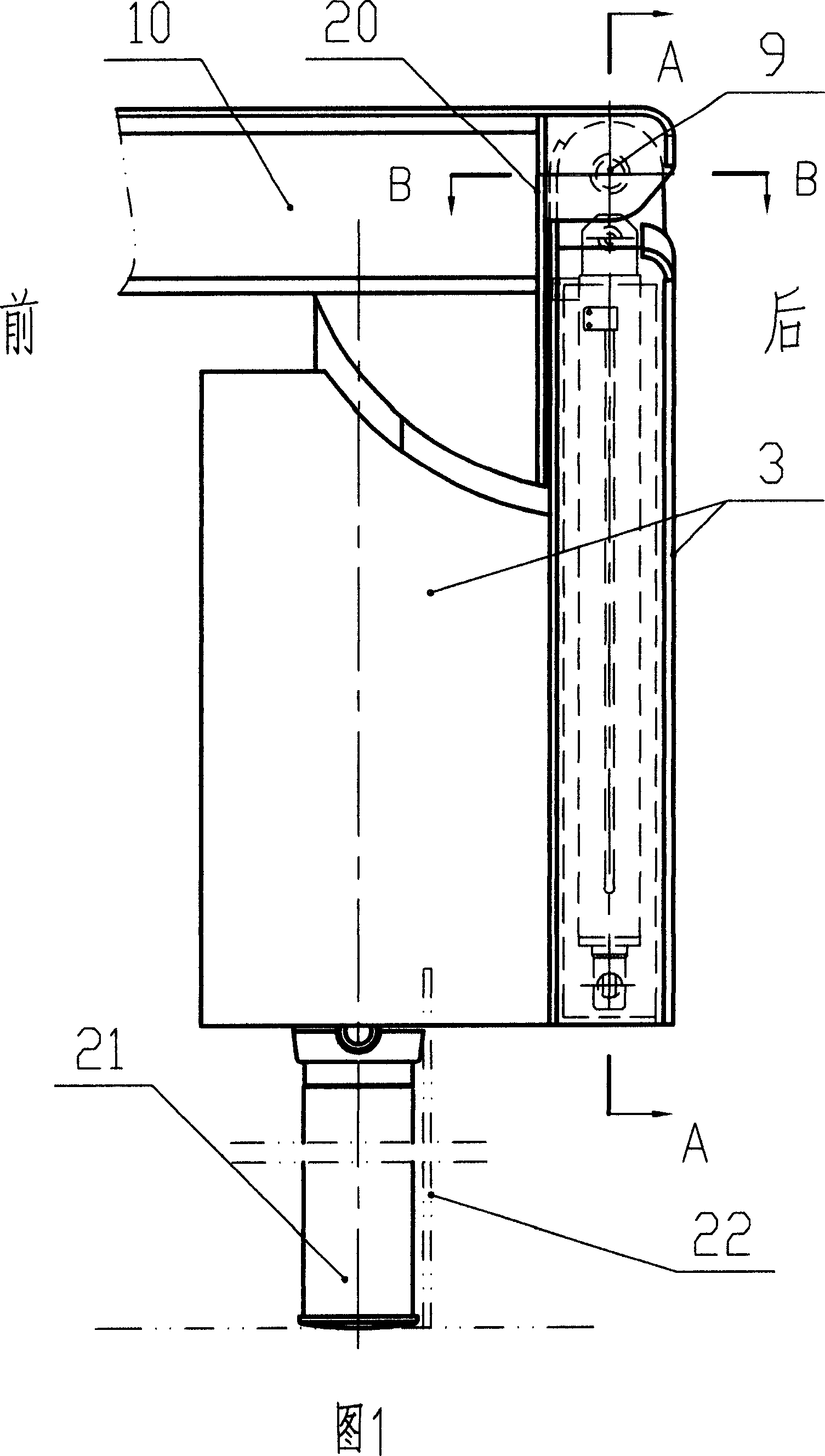

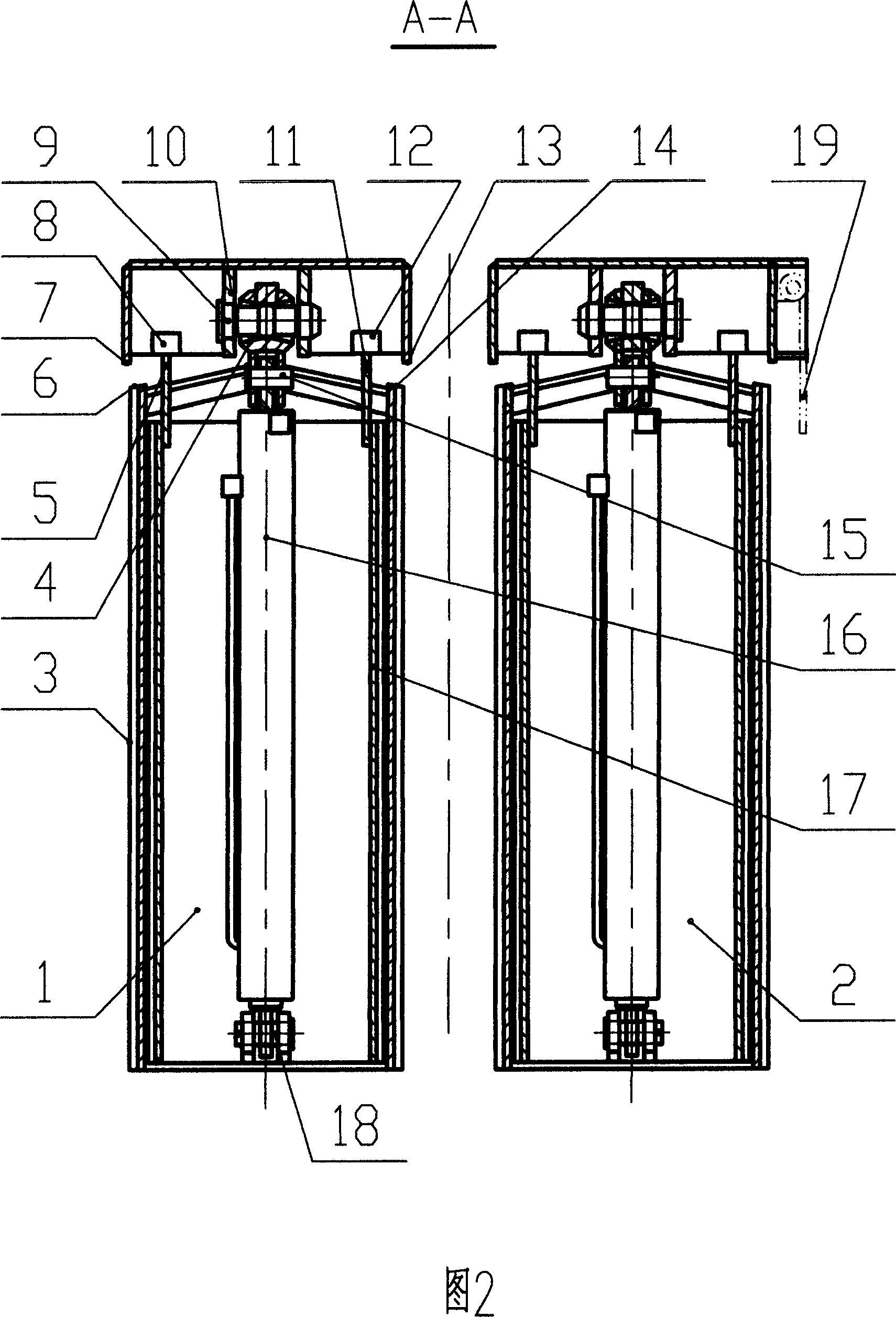

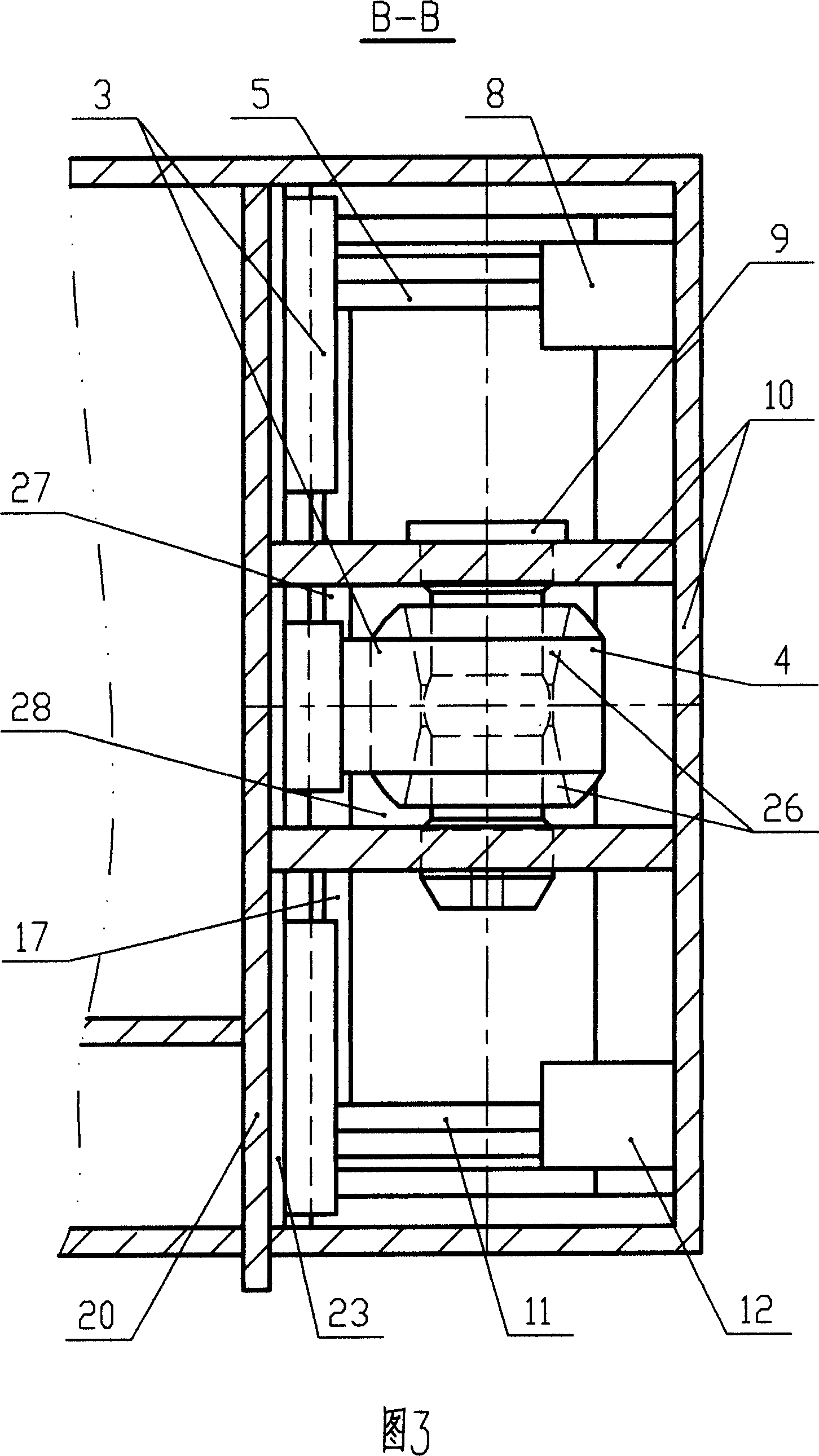

[0012] It can be known from the front view of the gangue-retaining device capable of putting top coal in Fig. 1 and Fig. 2 that the present embodiment is a gangue-retaining device used on a side-by-side roof beam type hydraulic support such as a suspension bracket, and the upper gangue-retaining device is composed of an upper gangue-retaining device. The device 1 is composed of an upper gangue-stopping device 2 which has basically the same structure as the upper gangue-stopping device 1, and the width of one upper gangue-stopping device is approximately equal to the width of a top beam. There is only one upper gangue-blocking device for the integral roof beam type supports such as fully mechanized mining supports and combined supports, and each support has only one, and its width is approximately equal to that of the entire support. The lower gangue device 22 connected together with the hydraulic prop 21 and the side guard plate 19 hinged on the side of the top beam 10 are only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com