What is a Variable Resistor?

A variable resistor is a versatile electronic component that allows its resistance to be adjusted or varied. Unlike fixed resistors with constant resistance, variable resistors can change their resistance based on user input or external conditions. This flexibility makes them indispensable in applications ranging from simple circuits to advanced electronic systems. This article will explore how variable resistors work, their types, and their diverse applications in modern electronics.

How Does a Variable Resistor Work?

Voltage-Dependent Resistance

Varistors adjust their resistance based on the applied voltage. When the voltage surpasses a specific threshold, called the switching voltage, their resistance drops dramatically. This occurs as conductive channels form or potential barriers reduce at the grain boundaries in materials like zinc oxide.

Mechanical Adjustment

Mechanical variable resistors use a wiper contact that moves along a resistive track to change resistance. The resistance value depends on the length of the material in contact with the terminals, providing precise, user-controlled adjustments.

Thermistor Response

Thermistors alter their resistance in response to temperature changes. As the temperature rises, the resistance decreases following a nonlinear relationship, making them ideal for temperature-sensitive applications.

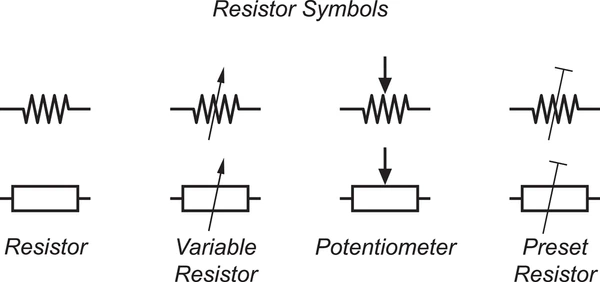

Types of Variable Resistors

Trimpot

A trimpot is a compact, three-terminal potentiometer designed for fine-tuning small resistance values. It is commonly used in calibration and circuit adjustment tasks where precision is essential.

Multi-Turn Potentiometer

The multi-turn potentiometer provides enhanced precision by allowing the wiper to make multiple rotations along the resistive element. This design ensures finer control over resistance compared to standard options.

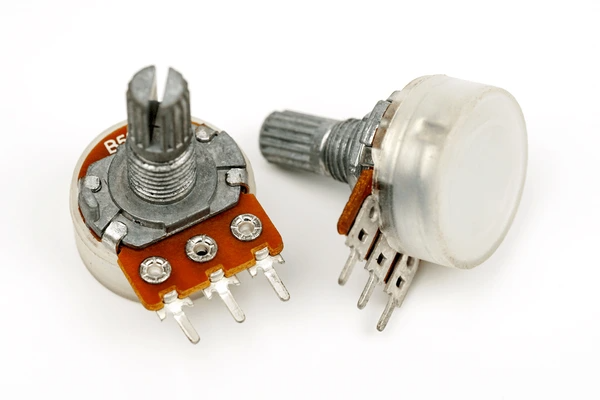

Rotary Potentiometer

This type of potentiometer uses a rotating wiper to adjust resistance continuously. It is widely used in audio systems and volume control for its smooth and consistent operation.

Linear Potentiometer

In a linear potentiometer, the wiper slides along a straight resistive track. This design delivers a linear and predictable resistance change, making it ideal for applications requiring straightforward adjustments.

Advantages of Using Variable Resistor

Noise Reduction

Adjustable resistors play a crucial role in minimizing noise in integrated circuits. Coupling them with a reference voltage source in switched-capacitor circuits reduces thermal noise, particularly benefiting sensitive ADCs and DACs.

Enhanced Signal Control

The ability to fine-tune resistance ensures precise control over signal levels, which is essential in audio controllers and CODECs. This flexibility optimizes performance under varying operating conditions.

Lower Power Consumption

Tuning resistance precisely reduces power usage in circuits like oscillators and voltage followers. This adjustment minimizes parasitic resistance and enhances capacitor performance.

Overvoltage Protection

In applications needing safety measures, adjustable resistors trigger mechanisms when current thresholds are exceeded, effectively preventing component damage.

Compact and Durable Design

Modern designs, including MEMS technology, offer durable solutions without movable parts. These are ideal for harsh environments and long-term systems.

Common Issues and Maintenance Tips for Variable Resistors

Inconsistent and Uncomfortable Operation

- Problem: Traditional designs often face inconsistent performance due to scattered characteristic curves and unstable pressure-sensitive components.

- Solution: Introducing conductive rubber as a pressure-sensitive member can improve stability and ease of use. Adding a buffer member further enhances operability. Alternatively, using an insulated substrate, resistor patterns, and a deformable contact held by a sturdy frame ensures smoother and more comfortable operation.

Scattering of Characteristic Change Curves

- Problem: Irregular characteristic curves reduce precision and result in a less reliable user experience.

- Solution: Employing advanced manufacturing techniques for the pressure-sensitive material improves consistency and enhances the reliability of the device.

Difficulty in Speed Operation and Sensory Feedback

- Problem: Speed adjustments can feel clunky, and poor feedback diminishes the user experience.

- Solution: A deformable conductive contact that adjusts the contact area under pressure offers better speed control and improved tactile feedback, ensuring a smoother experience.

Complicated Operation and Higher Cost

- Problem: Complex designs lead to challenging operation and increased costs.

- Solution: Simplifying the design by optimizing resistor patterns on an insulated substrate reduces manufacturing complexity and costs, leading to more user-friendly and affordable devices.

Applications of Variable Resistor

Analog Signal Processing

Adjustable resistors play a critical role in analog circuits, fine-tuning the performance of amplifiers, filters, and volume controllers. Their flexibility allows for precise adjustments, enhancing circuit functionality.

Sensors and Transducers

In sensors and transducers, adjustable resistors translate physical parameters like temperature, pressure, and position into electrical signals. Their changing resistance ensures accurate and reliable measurements.

Consumer Electronics

These components are essential in audio equipment for controlling volume, adjusting tone, and managing other settings, enhancing the user experience on everyday devices.

Industrial Electronics

Industrial control systems rely on adjustable resistors to regulate processes. By responding to feedback signals, they provide efficient and precise control.

Defense Electronics

Thanks to their precision and reliability, adjustable resistors are crucial in defense systems, supporting radar and communication technologies that demand high accuracy and stability.

Tunable Components

In RF and microwave circuits, adjustable resistors create tunable components like attenuators and matching networks. Their adaptability ensures optimal circuit performance.

Medical Devices

These resistors are integral in medical equipment, such as electrotherapy devices, allowing precise adjustments to treatment parameters like intensity and duration.

Automotive Systems

Modern vehicles use adjustable resistors for applications like temperature regulation, fuel injection, and ABS systems, ensuring precise control and improved safety.

Handheld Devices

Smartphones and tablets depend on adjustable resistors for touchscreens and user interfaces, ensuring responsive and seamless interaction for users.

Research and Development

In experimental setups, adjustable resistors provide the flexibility to test various scenarios, making them invaluable in scientific research and prototyping.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Variable Resistor Samsung Electronics Co., Ltd. | Achieves minimization of errors by varying resistance in a geometric ratio, applicable in analog amplifiers and analog filters. | Analog signal processing circuits requiring precise control of cutoff frequency and gain. |

| Linear Resilient Material Variable Resistor Gula Consulting LLC | Utilizes resilient material for adjustable resistance, suitable for terminal applications and sliding contact resistors. | Adjustable resistors, resistors for terminal applications, resistors with sliding contacts. |

| Variable Resistor Alps Alpine Co., Ltd. | Reduces change in overall resistance value, high oil repellency, and stable holding, addressing issues of poor microlinearity and productivity decline. | Applications requiring variable resistors with improved linearity and productivity. |

| Variable Resistor Circuit ROHM Co., Ltd. | Improves accuracy while reducing layout area by changing resistance value based on a resistance value change ratio. | Circuits requiring precise and compact variable resistor implementation. |

| Variable Resistor with Light Emitting Element Taiwan Alpha Electronic Co. Ltd. | Addresses the issue of severely affecting the maneuverability of the variable resistor. | Applications where variable resistors with light-emitting elements are required. |

Latest Technical Innovations in Variable Resistor

Advanced Materials and Designs

Non-Linear Resistors: Recent innovations include resistors made from zinc oxide blends with elements like bismuth and cobalt, offering superior energy absorption and thermal stability. Another breakthrough features silicon carbide (SiC) particles coated with aluminum oxide, delivering low dielectric constants and improved high-frequency performance while being easy to manufacture.

Serpentine Patterns: High-voltage resistive structures now use serpentine designs on semiconductor substrates. This layout improves reliability and addresses challenges like limited area availability and depletion region size.

Improved Manufacturing Techniques

Cost-Efficient Production: Advanced manufacturing processes, such as new lateral MOSFET structures, enhance performance while maintaining high voltage capacity at reduced costs. These innovations also offer greater production flexibility.

MEMS-Based Systems: A micro-system utilizing electro-explosion technology and MEMS solid switches eliminates movable parts. This design ensures long-term durability, making it ideal for harsh environments.

To get detailed scientific explanations of Variable Resistor, try Patsnap Eureka.