What is A V12 Engine?

A V12 engine is a twelve-cylinder piston engine with the cylinders arranged in a V configuration, typically with two banks of six cylinders each forming a 60-degree angle.

What is a V12 engine? Eureka Technical Q&A explains that it’s a high-performance engine with 12 cylinders arranged in a V configuration, known for its smooth power delivery, balance, and use in luxury and supercars.

History of the V12 Engine

The V12 engine configuration has been a popular choice for luxury and high-performance vehicles due to its inherent balance, smooth operation, and power delivery. The development of the V12 engine can be traced back to the early 20th century, with pioneering efforts from manufacturers like Cadillac, Lincoln, Packard, Hispano-Suiza, Itala, Maybach, Lagonda, Rolls-Royce, and Daimler.

Racing Heritage and Technological Advancements

In the 1930s, the V12 engine gained prominence in the world of motorsports, with iconic racing engines from Alfa Romeo, Auto Union, and Mercedes-Benz. These engines pushed the boundaries of performance and engineering, paving the way for future advancements. After World War II, Ferrari and Maserati embraced the V12 configuration, further refining its design and capabilities.

Jaguar’s Pioneering Role

Jaguar played a pivotal role in popularizing the V12 engine for modern luxury cars. Their new 60-degree V12 engine, introduced in the 1970s, featured an aluminum construction and innovative design elements. 10 This engine showcased Jaguar’s engineering prowess and set the stage for other manufacturers to follow suit.

BMW’s Cutting-Edge V12 Engines

BMW has been at the forefront of V12 engine development, introducing groundbreaking technologies such as High Precision Injection, twin turbocharging, and Valvetronic variable valve timing. Their V12 engines have achieved remarkable power outputs while meeting stringent emissions regulations, exemplifying the ongoing pursuit of performance and efficiency.

Advancements in Fuel Efficiency and Emissions

Recent years have seen a focus on improving fuel efficiency and reducing emissions in V12 engines. BMW’s Hydrogen 7 model featured a bi-fuel V12 engine capable of running on both gasoline and hydrogen, showcasing the potential for alternative fuel sources. Additionally, technologies like direct injection, variable valve timing, and turbocharging have been employed to enhance efficiency while maintaining the V12’s signature power delivery.

Future Outlook and Challenges

While the V12 engine remains a symbol of automotive excellence, its future is uncertain due to increasingly stringent emissions regulations and the shift towards electrification. Manufacturers may need to explore alternative powertrain solutions or implement advanced technologies to keep the V12 engine relevant in the evolving automotive landscape. Challenges such as weight reduction, thermal management, and packaging constraints will need to be addressed to ensure the V12’s continued viability.

V12 Engine performance specifications

Engine Configuration

- V12 engines have 12 cylinders arranged in a V configuration, typically with a 60° or 90° bank angle

- Cylinders are arranged in two banks of 6 cylinders each, with a single crankshaft

- This compact design allows for a shorter engine length compared to inline 12-cylinder engines

Displacement and Power Output

- V12 engines typically have displacements ranging from around 5.0L to 8.0L

- Power outputs can range from around 500 hp to over 700 hp for high-performance applications

- Peak torque values often exceed 500 lb-ft, with some engines producing over 700 lb-ft

Fuel Delivery and Combustion

- Both gasoline and diesel V12 engines have been produced

- Gasoline V12s may use port fuel injection or direct injection systems

- Diesel V12s utilize high-pressure common rail direct injection

- Advanced combustion systems like variable valve timing and cylinder deactivation can improve efficiency.

Performance Characteristics

- The compact V configuration allows for a low center of gravity and balanced weight distribution

- The large displacement enables high torque output across a broad rev range

- Sophisticated engine management systems optimize power delivery and drivability

- Dual overhead camshafts and 4-valve cylinder heads are common for high-revving performance

Applications of V12 Engine

Automotive Applications

V12 engines have been widely used in high-performance luxury and sports cars due to their smooth operation, high power output, and impressive torque characteristics. Some notable examples include:

- Luxury sedans and grand tourers: Mercedes-Benz S-Class, BMW 7 Series, Rolls-Royce, Bentley, Aston Martin, and Lamborghini models have featured V12 engines for their flagship models. The V12 configuration provides effortless acceleration and refinement befitting these ultra-luxury vehicles.

- Supercars and hypercars: V12 engines have been the powerplant of choice for many supercars and hypercars from manufacturers like Ferrari, Lamborghini, Aston Martin, and Mercedes-AMG. The high displacement and cylinder count allow for immense power outputs, often exceeding 700 hp, while maintaining a smooth, refined delivery.

Marine Applications

The compact packaging and high power density of V12 engines make them suitable for marine applications where space is limited:

- High-performance boats and yachts: V12 engines, particularly those derived from automotive applications, have been used to power high-end recreational boats and yachts requiring high speeds and acceleration.

- Commercial marine vessels: Certain commercial vessels, such as ferries and patrol boats, have employed V12 engines for their power and reliability requirements.

Industrial Applications

While less common, V12 engines have found use in various industrial applications that demand high power output and durability:

- Generators and backup power systems: The high displacement and multi-cylinder design of V12 engines allow them to generate substantial power for industrial generators and backup power systems

- Heavy machinery and equipment: Some heavy-duty construction and mining equipment have utilized V12 engines to meet their immense power requirements.

Technological Advancements

To meet stringent emissions regulations and improve fuel efficiency, V12 engines have undergone several technological advancements:

- Turbocharging and downsizing: Manufacturers have downsized V12 engines while incorporating turbocharging to maintain power output while improving fuel economy. Examples include the twin-turbocharged 3.8L V12 in the Ferrari 812 Superfast.

- Cylinder deactivation: Some V12 engines feature cylinder deactivation technology, which deactivates a portion of the cylinders under light loads to improve efficiency. Mercedes-Benz and BMW have implemented this in their V12 models.

- Hybrid systems: A few automakers have combined V12 engines with hybrid systems, such as the LaFerrari and Mercedes-AMG Project One, to further enhance performance and efficiency.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Rolls-Royce Cullinan | The 6.75-litre twin-turbo V12 engine delivers 563 bhp and 850 Nm of torque, providing effortless acceleration and refinement befitting the ultra-luxury SUV. | Luxury SUVs and high-end off-road vehicles requiring immense power and torque. |

| Ferrari 812 Superfast | The 6.5-litre naturally aspirated V12 engine produces 789 bhp and 718 Nm of torque, enabling a 0-62 mph time of 2.9 seconds and a top speed of 211 mph. | High-performance supercars and track-focused vehicles demanding exceptional power and responsiveness. |

| Lamborghini Aventador SVJ | The 6.5-litre naturally aspirated V12 engine generates 770 bhp and 720 Nm of torque, propelling the Aventador SVJ to a top speed of 217 mph and setting a Nürburgring production car lap record. | Extreme performance supercars and hypercars prioritising outright speed and track capabilities. |

| Mercedes-AMG G63 | The 4.0-litre twin-turbo V12 engine delivers 630 bhp and 1,000 Nm of torque, enabling the G63 to accelerate from 0-62 mph in 4.5 seconds despite its off-road capabilities. | High-performance luxury off-road vehicles requiring immense power and torque for both on-road and off-road use. |

| Azimut Grande 35 Metri | The 35-metre yacht is powered by twin 2,638 hp V12 engines, enabling a top speed of 28 knots and a cruising range of 3,800 nautical miles. | High-performance luxury yachts and boats requiring exceptional power and range capabilities. |

Latest Technical Innovations of V12 Engine

Efficiency and Performance Optimization

- Variable valve timing and lift systems allow optimizing valve operation for maximum efficiency across the engine’s operating range. Dual VVT-I technology enhances intake efficiency for improved torque and power delivery.

- Direct fuel injection, both high-pressure and low-pressure, improves fuel economy and emissions while suppressing knocking limitations on power output.

- Cylinder deactivation and engine downsizing with electric turbocharging/supercharging provide supplementary power when needed while operating more efficiently under lower loads.

Structural Innovations

- Hollow crankshaft design reduces weight and improves engine balance for smoother operation.

- Opposed-piston designs with two pistons per cylinder improve thermal efficiency and packaging.

- Modular engine block designs with multiple cylinder banks coupled together enable scalable, higher output configurations.

Advanced Combustion Systems

- Variable compression ratio systems optimize the compression ratio for different operating conditions.

- Homogeneous charge compression ignition (HCCI) enables low-temperature combustion for improved efficiency.

- Perforated cone fuel atomizers improve fuel-air mixing for cleaner, more efficient combustion.

Electrification and Hybridization

- Integrated starter generators enable engine auto-start/stop, regenerative braking, and torque assist functions.

- Fully hybrid V12 designs combine the engine with electric motors for higher system efficiency.

- Artificial intelligence and self-optimizing controls continuously adapt operation for peak efficiency.

Technical Challenges of V12 Engine

| Opposed-Piston Engine Design | Developing opposed-piston engine designs with two pistons per cylinder to improve thermal efficiency and packaging. |

| Variable Compression Ratio Systems | Implementing variable compression ratio systems to optimise engine performance across different operating conditions. |

| Integrated Engine and Transmission Design | Designing engines with integrated transmissions to improve mechanical efficiency and packaging. |

| Cylinder Deactivation and Downsizing | Incorporating cylinder deactivation and engine downsizing with electric turbocharging/supercharging for improved efficiency. |

| Advanced Combustion Systems | Developing advanced combustion systems such as variable valve timing and direct fuel injection for enhanced performance and emissions. |

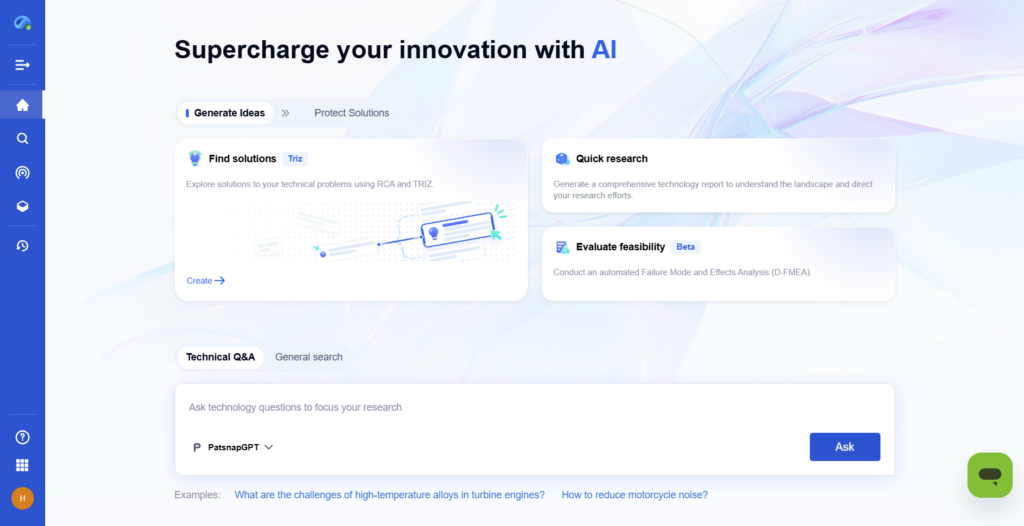

How PatSnap Eureka Accelerates V12 Engine Innovation

The V12 engine remains a benchmark of high-performance engineering, but advancing its design requires constant innovation in combustion efficiency, emissions reduction, and hybrid integration. PatSnap Eureka equips R&D and engineering teams with the insights they need to stay ahead—by unlocking faster access to global patents, technical breakthroughs, and emerging industry trends.

- Patent Intelligence: Eureka scans global patent databases to uncover the latest developments in V12 engine architecture, fuel injection systems, and thermal management—helping teams reduce duplication and fast-track innovation.

- Competitive Landscape Tracking: Benchmark how leading automotive and aerospace manufacturers are developing V12 engine technologies, from performance tuning to electrified powertrains.

- Trend Forecasting: With AI-driven analytics, Eureka identifies where V12 engines are still evolving—such as in ultra-luxury vehicles, motorsports, and defense applications—helping teams align R&D with future opportunities.

- Technical Clustering: Visual clustering reveals hotspots in V12 engine innovation, including lightweight material integration, emissions compliance systems, and hybrid compatibility.

Whether refining combustion strategies or exploring next-gen engine configurations, Eureka empowers faster, smarter, and more strategic decisions in V12 engine innovation.

To get detailed scientific explanations of the v12 engine, try Patsnap Eureka.