In today’s highly competitive industries, quality, efficiency, and consistency are more than just goals—they are essential. Six Sigma is a data-driven methodology designed to eliminate defects, reduce variability, and enhance operational performance. Whether you’re in manufacturing, healthcare, software, or logistics, Six Sigma provides a systematic approach to continuous improvement.

This article explains what Six Sigma is, how the DMAIC process works, what tools are commonly used, and how certification levels function. Additionally, we’ll show how integrating PatSnap’s Eureka Feasibility Analysis AI Agent can supercharge Six Sigma efforts with AI-powered root cause analysis, process modeling, and risk validation.

What Is Six Sigma?

Six Sigma is a disciplined, data-centric methodology for process improvement. Developed at Motorola in the 1980s and later adopted by companies like GE, Six Sigma aims to reduce process variation and drive performance improvements by identifying and eliminating the root causes of defects.

The term “Six Sigma” refers to a statistical concept—achieving a process with no more than 3.4 defects per million opportunities (DPMO). This level of quality represents near-perfect performance and is achieved through a structured problem-solving approach.

The DMAIC Process: Core of Six Sigma Methodology

At the heart of Six Sigma is the DMAIC process, a five-phase problem-solving model used to improve existing processes. Each phase is data-driven and focuses on eliminating waste and variability.

1. Define

Clearly define the project goals, customer requirements, and scope. This phase involves mapping processes, identifying problems, and outlining success criteria.

2. Measure

Collect and analyze current process data to establish baseline performance. Tools such as process maps, histograms, and control charts are used to assess process capability and identify variation.

3. Analyze

Identify root causes of defects using statistical analysis. Techniques like regression analysis, cause-and-effect diagrams, and hypothesis testing help pinpoint problem areas.

4. Improve

Develop and implement data-driven solutions to eliminate root causes. Design of Experiments (DOE), mistake-proofing, and Lean principles are often used in this stage.

5. Control

Maintain improvements using control plans, monitoring systems, and standardized procedures. Statistical Process Control (SPC) tools are deployed to ensure sustained performance.

Common Tools Used in Six Sigma Projects

Six Sigma projects rely on a variety of analytical and visual tools throughout the DMAIC cycle:

- Fishbone Diagram: Helps in identifying the causes of a problem.

- Control Charts: Used for monitoring process performance over time.

- Failure Mode and Effects Analysis (FMEA): Helps in identifying potential failure modes and their effects.

- Statistical Process Control (SPC): Involves using statistical methods to monitor and control a process.

- Design of Experiments (DOE): Used for understanding the relationship between factors affecting a process and the output of that process.

These tools empower teams to work with data objectively and methodically address inefficiencies.

Six Sigma Certification Levels Explained

Professionals can earn Six Sigma certifications to demonstrate their expertise and contribute more effectively to improvement projects. Here are the main levels:

- White Belt

White Belt is the entry point for anyone new to process improvement. It introduces basic concepts and core principles. People with White Belt training often support local teams and help manage organizational change. They play a helpful role in small-scale problem-solving efforts. - Yellow Belt

Yellow Belt offers a deeper look into the tools and applications of process improvement. These individuals support project teams by identifying problems and contributing to solutions. They often work alongside Green and Black Belts to streamline processes and reduce waste. - Green Belt

Green Belt professionals gain strong skills in data analysis and problem-solving. They typically lead smaller projects within departments. They also support Black Belts by managing data collection and performing detailed analysis. Their focus remains on improving quality and boosting efficiency. - Black Belt

Black Belt certification shows advanced knowledge and leadership. Black Belts lead major improvement projects and drive measurable results. They also mentor Green and Yellow Belts and help align initiatives with business goals. Their expertise plays a key role in organizational success. - Master Black Belt

Master Black Belt is the top certification level in process optimization. These individuals guide strategy and set key performance metrics. They act as high-level consultants and coach other belt holders. They ensure that process improvement stays aligned with company-wide goals.

Each level deepens understanding of data analysis, project management, and Lean Six Sigma principles.

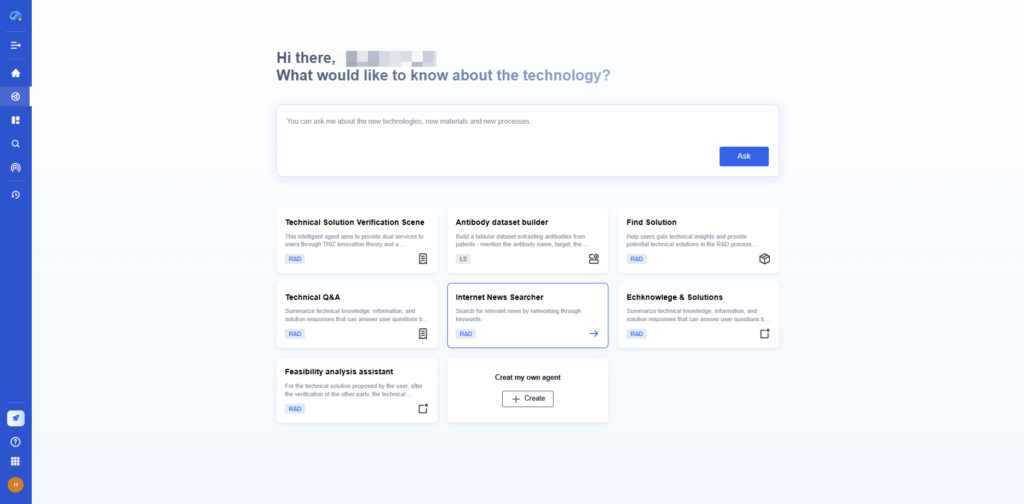

How Eureka AI Agent Enhances Six Sigma Implementation

While Six Sigma offers a structured framework, the process often demands time-intensive data gathering, root cause analysis, and validation. This is where PatSnap’s Eureka Feasibility Analysis AI Agent offers a powerful advantage—augmenting traditional Six Sigma with AI, automation, and technical intelligence.

1. Automated Root Cause Identification

Eureka uses AI-driven pattern recognition to identify likely causes of defects based on historical project data, patent repositories, and real-world failure modes. This enhances the “Analyze” phase by reducing manual analysis time.

2. Real-Time Feasibility and Risk Validation

In the “Improve” phase, Eureka evaluates the feasibility of proposed solutions by simulating process performance and detecting unintended consequences. It helps teams avoid implementing unproven or risky changes.

3. AI-Assisted FMEA

During the “Measure” and “Control” phases, Eureka automatically generates Failure Mode and Effects Analysis reports by analyzing material behavior, design complexity, and operating conditions. This improves risk assessment quality and speeds up documentation.

4. Innovation Opportunity Discovery

For organizations using Six Sigma not just for optimization but also for innovation, Eureka identifies technical gaps and inventive principles that align with Lean principles—offering insights for next-gen product and process designs.

5. Seamless Reporting and Knowledge Sharing

Eureka compiles analytics, simulation outcomes, and project history into structured reports, perfect for Six Sigma project review boards or audits. This ensures every DMAIC stage is documented with traceable data.

Real-World Example

Consider a company optimizing a multi-level dynamically adjustable silencer. In the “Measure” phase, process data shows inconsistency in noise reduction due to chamber misalignment. Traditional analysis is slow, but Eureka quickly flags dynamic actuator response time as the root cause.

In the “Improve” phase, engineers use Eureka to simulate alternative chamber control algorithms and actuator materials. Eureka validates the feasibility and long-term reliability of each solution. In the “Control” phase, Eureka assists in real-time monitoring strategy setup using predictive failure models, ensuring sustainable performance improvements.

This synergy between Six Sigma structure and Eureka’s intelligence results in faster cycles, more effective fixes, and better long-term outcomes.

Benefits of Combining Six Sigma and Eureka AI Agent

| Benefit | Six Sigma Alone | Six Sigma + Eureka AI Agent |

|---|---|---|

| Root Cause Analysis | Manual, time-intensive | Automated with historical data and AI |

| Solution Feasibility | Engineer-driven trials | Simulation-based technical validation |

| FMEA Creation | Spreadsheet-based, manual | AI-generated based on real-world scenarios |

| Process Innovation | Depends on team creativity | Informed by patent and technical databases |

| Report Generation | Static and time-consuming | Auto-generated, dynamic, and traceable |

Conclusion

Six Sigma has transformed how organizations think about quality and continuous improvement. But in the era of rapid innovation, traditional tools are no longer enough. PatSnap’s Eureka Feasibility Analysis AI Agent enhances Six Sigma by adding speed, intelligence, and reliability to every phase of the DMAIC cycle.

Whether you’re looking to reduce defects, optimize manufacturing systems, or innovate process design, combining Six Sigma with Eureka helps you make smarter decisions—backed by data, driven by AI, and built for success.

To get detailed scientific explanations of Six Sigma, try Patsnap Eureka.