Polyaryletherketone (PAEK) is a high-performance thermoplastic polymer that is making waves in industries worldwide. Known for its strength, chemical resistance, and thermal stability, PAEK is an ideal choice for applications in automotive, aerospace, medical, and other high-tech sectors. In this article, we’ll explore PAEK’s unique features, its advantages, key applications, and the latest trends that are shaping its future.

What is Polyaryletherketone (PAEK)?

Polyaryletherketone (PAEK) is part of a family of engineering thermoplastics. It is prized for its exceptional mechanical properties, chemical resistance, and ability to withstand high temperatures. The polymer is made through the reaction of an aromatic ether and a ketone. These qualities make it highly suitable for demanding environments that require durability and precision.

Key Properties of Polyaryletherketone

PAEK stands out for several remarkable properties:

- Thermal Stability: PAEK remains stable at temperatures up to 250°C (482°F), allowing it to perform well in high-temperature environments.

- Chemical Resistance: It resists acids, bases, solvents, and many aggressive chemicals, making it valuable in harsh industrial conditions.

- Mechanical Strength: With high tensile strength, PAEK offers excellent wear resistance, even under stress.

- Electrical Insulation: PAEK is also known for its superb insulating properties, making it useful in electrical and electronic applications.

- Low Friction: Its low friction coefficient is ideal for bearing and wear-resistant applications.

Advantages of Polyaryletherketone Over Other Materials

When compared to other high-performance polymers like PEEK, PPS, and PTFE, PAEK offers several advantages:

- Higher Mechanical Performance: PAEK maintains superior strength and toughness at high temperatures, even under load.

- Greater Processing Flexibility: Unlike some high-performance polymers, PAEK can be processed using conventional thermoplastic methods such as injection molding and extrusion.

- Cost-Effectiveness: While still a high-performance material, PAEK tends to be more affordable than PEEK, balancing performance and cost.

Applications of Polyaryletherketone

💡 Curious about the applications of Polyaryletherketone (PAEK)? Eureka Technical Q&A offers detailed insights into its uses across industries like aerospace, automotive, and medical, helping you understand how this high-performance polymer can benefit your projects with its durability and heat resistance.

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Biomedical implants and devices Stony Brook University | Comparable mechanical strength and elastic modulus to human bone, enabling PAEKs as viable alternatives to metal-based implants. | Orthopedics, craniofacial and cardiothoracic surgery, cardiovascular and dental medicine, tissue engineering, drug delivery systems. |

| Engineering plastics South China University of Technology | High-performance thermoplastic with exceptional mechanical, thermal, and chemical properties. | Various engineering applications requiring durability and resistance to extreme conditions. |

| PEEK compounds and components Victrex Europa GmbH | Excellent creep resistance, wear resistance, and chemical resistance under high pressure and high temperature (HPHT) conditions, increasing reliability and extending equipment life. | Oil and gas industry, aerospace, automotive, and other applications requiring high-performance materials in challenging environments. |

| Polymer compositions with PEEK Ticona LLC | Improved melt flow properties, enhanced mechanical performance, and hydrolytic stability through blending PEEK with other polymers and reinforcing fibers. | Applications requiring low viscosity, strong mechanical properties, and resistance to hydrolysis or flame exposure. |

| Hydrolysis-resistant PAEK fabrics Albany International Corp. | Woven monofilament threads of hydrolysis-resistant PAEK provide high modulus of elongation, suitable for industrial conveying applications. | Industrial processing and conveying applications requiring hydrolysis resistance at elevated temperatures. |

PAEK’s unique properties make it a versatile material across various industries. Here are some of its key applications:

Automotive Industry

In automotive manufacturing, PAEK’s strength and thermal stability make it ideal for engine components, electrical connectors, and transmission systems. It is also used in parts exposed to high temperatures and mechanical stress.

Aerospace and Aviation

In aerospace, engineers use PAEK for lightweight, high-strength components that must perform under extreme conditions. You often find it in aircraft parts like seals, gaskets, and bearings, where durability is essential.

Medical and Healthcare

The medical field highly values PAEK due to its biocompatibility. Doctors use it in surgical instruments, prosthetics, and implants, and its ability to withstand sterilization processes makes it highly reliable for medical applications.

Oil and Gas Industry

PAEK’s chemical resistance makes it the material of choice for the oil and gas industry, where it’s used in seals, valves, and pumps. Its durability in harsh environments improves operational efficiency.

Electronics and Electrical

PAEK’s excellent insulating properties make it an ideal material for electrical connectors and circuit boards. Its resistance to high temperatures also ensures that it maintains integrity in demanding electronic applications.

Performance Comparison: PAEK vs. Other Polymers

| Property | PAEK | PEEK | PPS | PTFE |

|---|---|---|---|---|

| Temperature Stability | Up to 250°C (482°F) | Up to 300°C (572°F) | Up to 260°C (500°F) | Up to 260°C (500°F) |

| Chemical Resistance | Excellent | Excellent | Good | Excellent |

| Mechanical Strength | High | Very High | Moderate | Low |

| Cost | More affordable than PEEK | Expensive | Less expensive | Affordable |

| Processing Ease | Easy to process | Difficult to process | Moderate | Difficult to process |

Challenges of Polyaryletherketone

Although PAEK offers several advantages, it does have some challenges:

- Processing Complexity: Due to its high melting point, PAEK requires specialized equipment for molding and extrusion.

- Cost: While more affordable than PEEK, PAEK can still be expensive compared to common thermoplastics, limiting its use in low-cost applications.

- Limited Availability: PAEK is less widely available than other polymers like PEEK or nylon, which can hinder its adoption in certain markets.

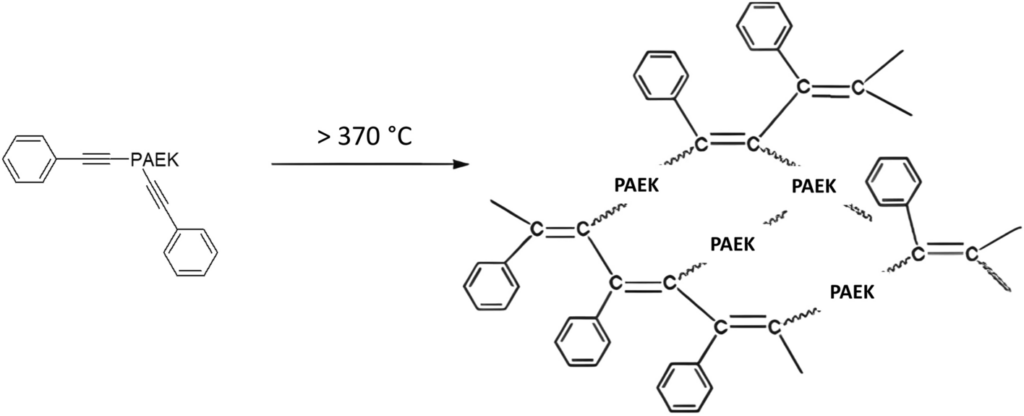

Future Trends in Polyaryletherketone Development

Research into PAEK is ongoing, with several trends emerging that promise to expand its capabilities:

- Nanocomposites: Adding nanoparticles to PAEK can enhance its mechanical strength, wear resistance, and conductivity, unlocking new possibilities for high-performance applications.

- Sustainability: Efforts to make PAEK production more eco-friendly include improving manufacturing processes and exploring recycling methods.

- Hybrid Materials: By combining PAEK with materials like carbon fiber or glass fibers, manufacturers can boost its performance for use in sectors like aerospace and automotive.

How Eureka by PatSnap Enhances PAEK Innovation

What is Eureka by PatSnap?

Eureka by PatSnap is an AI-powered innovation intelligence tool that accelerates R&D in polymer science and materials engineering.

How Eureka Benefits PAEK R&D

- Patent Analysis: Eureka helps identify the latest patents related to PAEK, allowing researchers to stay ahead of trends.

- Competitive Intelligence: It provides insights into key players and market leaders in the PAEK space.

- Technology Roadmapping: Eureka helps manufacturers forecast PAEK innovations and maintain a competitive edge.

Conclusion

Polyaryletherketone (PAEK) is rapidly becoming a go-to material for industries requiring high-performance polymers. Its outstanding thermal stability, mechanical strength, and chemical resistance make it essential for applications in automotive, aerospace, medical, and more. As research continues to drive new innovations, PAEK will undoubtedly play a critical role in shaping the future of engineering materials. By using tools like Eureka by PatSnap, businesses can stay at the forefront of PAEK developments and leverage new opportunities.

🚀 Stay ahead of the competition by exploring the latest trends in polymer innovation with Eureka by PatSnap!

To get detailed scientific explanations of Polyaryletherketone, try Patsnap Eureka.