Introduction

The LQ4 6.0L LS engine is a robust and versatile member of General Motors’ LS family, known for its reliability and performance. With a cast iron block, aluminum heads, and a compression ratio of 9.4:1, this engine was designed to handle the demands of heavy-duty trucks, SUVs, and vans while maintaining efficiency and durability. Producing 300–325 horsepower and up to 370 lb-ft of torque, the LQ4 has also become a favorite for engine swaps and performance builds. Its affordability, durability, and compatibility with aftermarket parts make it a cornerstone of GM’s LS engine lineup.

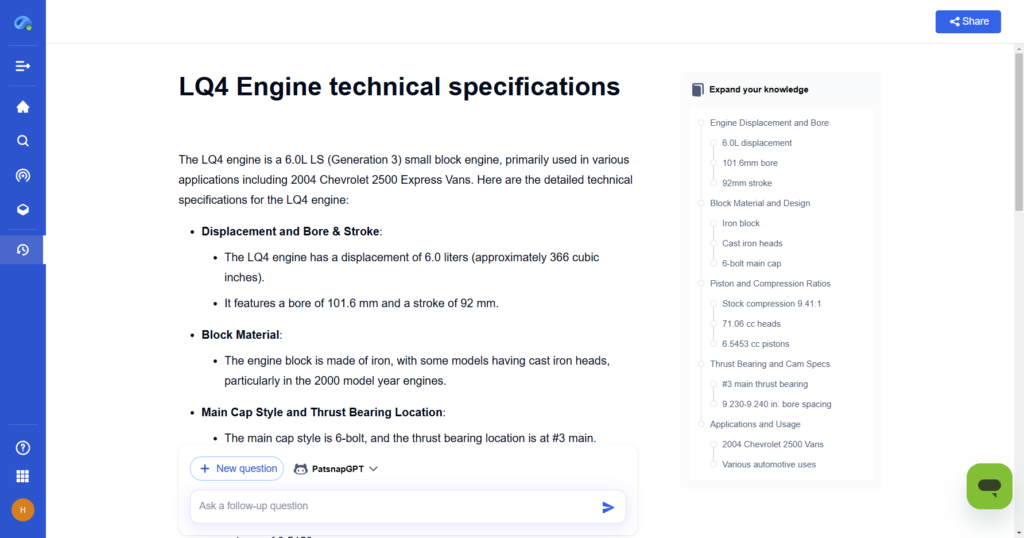

What are the key features of the LQ4 engine? Eureka Technical Q&A highlights its 6.0L displacement, iron block durability, and versatility, making it a popular choice for trucks, SUVs, and performance builds.

Key Features of the LQ4 Engine

- Power and Performance: The LQ4 6.0L LS engine is known for its strong power output and smooth performance. It features a displacement of 6.0 liters and is equipped with a robust crankshaft and connecting rods to handle heavy loads and high torque requirements.

- Fuel System: It comes with a fuel injection system that provides precise control over fuel delivery, enhancing both performance and fuel efficiency. The engine is designed to meet stringent emissions standards, making it environmentally friendly.

- Cooling System: The LQ4 engine has an advanced cooling system that includes a high-capacity radiator and a robust cooling fan to maintain optimal operating temperatures, even under heavy loads or in extreme environments.

Technical Specifications

- Engine Type: The LQ4 6.0L LS engine is a 6.0-liter V8 engine, part of the LS engine family known for its performance and reliability.

- Horsepower: It produces 346 horsepower (hp), providing ample power for various applications.

- Torque: The engine delivers 380 lb-ft of torque, ensuring strong performance and towing capacity.

- Compression Ratio: The compression ratio of the LQ4 6.0L LS engine is 9.4:1, which contributes to its power output and efficiency.

- Fuel Efficiency: While it is a powerful engine, it also offers reasonable fuel efficiency for its class, making it a practical choice for many users.

Looking for LQ4 Engine technical specifications? Eureka Technical Q&A provides expert insights into engine performance, materials, and design features, helping you understand the key specs that matter most.

Performance and Tuning Potential

Aftermarket Upgrades

- Camshaft Upgrades: Upgrading to performance camshafts can significantly increase power output by optimizing valve timing and lift. This can lead to substantial gains in both horsepower and torque.

- Intake and Exhaust Systems: High-flow intake manifolds and performance exhaust systems can improve airflow and reduce backpressure, further enhancing power and torque.

- Forced Induction: Superchargers and turbochargers are popular for forced induction. These systems force more air into the engine, allowing for dramatic increases in power output. However, they also require additional cooling and management systems.

- Custom Builds: Custom engine builds often involve a combination of the above upgrades, along with other modifications like ported cylinder heads, forged internals, and high-performance fuel injectors.

ECU Tuning

- Tuning Potential: The ECU (Engine Control Unit) plays a crucial role in managing the engine’s performance. Tuning the ECU can optimize fuel injection, ignition timing, and boost pressure (if applicable), leading to significant power gains.

- Software and Hardware Tuning: There are both software-based tuning solutions that modify the ECU’s programming and hardware-based solutions that involve reflashing the ECU or installing aftermarket units.

Comparison with Other LS Engines

Engine Specifications

- LQ4 6.0L LS Engine: This engine typically produces around 325 horsepower and 370 lb-ft of torque. It features a cast iron block and aluminum cylinder heads, making it suitable for heavy-duty applications.

- Other LS Engines:

- LQ1 6.0L LS Engine: Similar to the LQ4, but with a slightly different camshaft profile, producing around 320 horsepower and 370 lb-ft of torque.

- LQ9 6.0L LS Engine: Known for its performance capabilities, producing around 450 horsepower and 450 lb-ft of torque. It features a forged steel crankshaft and a more aggressive camshaft profile.

- L92 6.2L LS Engine: A smaller displacement engine, producing around 403 horsepower and 417 lb-ft of torque. It features a cast aluminum block and cylinder heads, making it lighter and more suitable for lighter-duty applications.

Applications

- LQ4 6.0L LS Engine: Commonly used in heavy-duty trucks and applications where durability and power are critical.

- Other LS Engines:

- LQ1 6.0L LS Engine: Often used in similar heavy-duty applications as the LQ4.

- LQ9 6.0L LS Engine: Typically used in performance-oriented vehicles, including some Chevrolet trucks and performance cars.

- L92 6.2L LS Engine: Used in a variety of applications, including some light-duty trucks and performance cars, due to its balance of power and weight.

Performance Differences

- The LQ4 and LQ1 engines are very similar in terms of power output and application, with the main difference being the camshaft profile, which can affect performance characteristics such as torque curve and responsiveness.

- The LQ9 engine stands out due to its higher power output and use of a forged steel crankshaft, making it more suitable for high-performance applications.

- The L92 engine, with its smaller displacement, offers a good balance of power and weight, making it suitable for a wider range of applications.

Reliability and Durability

- All LS engines, including the LQ4, are known for their reliability and durability. They have a reputation for being robust and long-lasting, especially in heavy-duty applications.

- The cast iron block of the LQ4 engine contributes to its durability, making it well-suited for demanding environments.

Maintenance and Reliability

- Oil Changes: Regular oil changes are crucial to maintain the engine’s performance and longevity. The recommended oil change interval is typically every 5,000 to 7,500 miles, depending on the operating conditions.

- Filter Replacements: Replace air and fuel filters as scheduled by the manufacturer to maintain performance and fuel efficiency.

- Cooling System Checks: Inspect the cooling system regularly for leaks or damage, and maintain coolant levels per manufacturer specifications.

- Electrical System Checks: Test the battery, starter motor, and other electrical components periodically to ensure proper functionality.

Applications of the LQ4 Engine

- Heavy-Duty Trucks: The LQ4 engine is often used in heavy-duty trucks due to its ability to handle high torque and towing capacity. Its design allows it to perform efficiently under heavy loads, making it suitable for applications such as semi-trucks and construction vehicles.

- Motorhomes and RVs: The engine’s reliability and power make it a popular choice for motorhomes and recreational vehicles (RVs). It provides the necessary power for towing trailers and handling the weight of the vehicle, ensuring a comfortable and safe journey.

- Marine Applications: The LQ4 engine is also used in marine environments, such as boat engines. Its durability and ability to withstand harsh conditions make it suitable for use in boats and other watercraft.

- Industrial Equipment: The engine’s power and reliability make it a good fit for various industrial applications, including generators and other heavy machinery. Its ability to operate under demanding conditions is beneficial for industrial use.

- Specialty Vehicles: The LQ4 engine is sometimes used in specialty vehicles, such as ambulances and fire trucks. Its performance characteristics make it suitable for vehicles that require a balance of power and reliability.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Chevrolet Silverado/GMC Sierra | Robust and powerful engine, capable of handling heavy loads and towing. | Heavy-duty trucks, SUVs, and vehicles requiring high torque and towing capacity. |

| Motorhomes and RVs | Reliable and durable engine, suitable for long-distance travel and towing trailers. | Recreational vehicles, motorhomes, and other vehicles used for camping and travel. |

| Marine Applications | Designed to withstand harsh marine environments and provide reliable power. | Boats, yachts, and other watercraft requiring a powerful and durable engine. |

| Industrial Equipment | Powerful and efficient engine, capable of operating under demanding conditions. | Generators, construction machinery, and other industrial equipment requiring a robust and reliable power source. |

| Specialty Vehicles | Versatile and adaptable engine, suitable for various specialty vehicle applications. | Specialty vehicles, such as race cars, off-road vehicles, and custom builds, where high performance and durability are required. |

Latest Technical Innovations in the LQ4 Engine

Fuel Injection System

- The LQ4 6.0L LS engine features a state-of-the-art fuel injection system that enhances fuel efficiency and performance. This system includes advanced fuel injectors that provide precise control over fuel delivery, optimizing combustion efficiency.

Cylinder Head Design

- The engine boasts a high-performance cylinder head design that improves airflow and thermal efficiency. This design includes features such as larger intake and exhaust ports, which contribute to better power output and reduced emissions.

Camshaft and Valvetrain

- The LQ4 6.0L LS engine employs a dual-overhead camshaft (DOHC) design with roller finger followers, which enhances valve operation and reduces friction. This setup allows for more precise control over the intake and exhaust valves, improving engine performance and responsiveness.

Oiling System

- The engine features a robust oiling system that ensures optimal lubrication of all moving parts. This includes a high-pressure oil pump and a dedicated oil cooler, which help maintain oil temperature and pressure, even under high-load conditions.

Cooling System

- The cooling system of the LQ4 6.0L LS engine is designed for efficiency and reliability. It includes features such as a high-capacity radiator and an electric cooling fan, which work together to maintain optimal engine temperature, even during prolonged high-performance operation.

Exhaust System

- The engine is equipped with a sophisticated exhaust system that includes a close-coupled catalytic converter and a high-flow exhaust manifold. This setup helps in reducing emissions and improving fuel efficiency by optimizing exhaust gas flow.

Electronic Control Systems

- The LQ4 6.0L LS engine incorporates advanced electronic control systems, including an engine control unit (ECU) that monitors and controls various engine parameters in real-time. This system allows for precise tuning of engine performance and helps in implementing advanced features such as knock control and fuel cut-off.

Materials and Manufacturing

- The engine uses advanced materials and manufacturing techniques to enhance durability and performance. This includes the use of lightweight materials for the engine block and cylinder heads, as well as advanced casting and machining processes to ensure precise tolerances and high-quality finishes.

FAQs

- What vehicles came with the LQ4 engine?

The LQ4 was found in GM trucks and SUVs like the Chevy Silverado 2500/3500, GMC Sierra HD, Chevy Suburban, and Cadillac Escalade from 1999 to 2007. - How much power can an LQ4 handle with upgrades?

With stock internals, the LQ4 can handle around 600 horsepower with proper tuning. Upgraded components can push it to over 1,000 horsepower. - Is the LQ4 good for engine swaps?

Absolutely! Its affordability, durability, and compatibility with the LS platform make it a favorite for muscle cars, off-road builds, and hot rods. - Can the LQ4 handle forced induction?

Yes! The LQ4’s low compression ratio (9.4:1) makes it ideal for turbocharging or supercharging. Many tuners take advantage of this feature. - What are the downsides of the LQ4 compared to other LS engines?

The main downside is its weight, as the cast iron block is heavier than the aluminum blocks found in engines like the LS1 or LS3.

To get detailed scientific explanations of the LQ4 engine, try Patsnap Eureka.

Learn more

2024 Toyota Hilux Review: Everything You Need to Know

The LS3 Engine: Unleashing Power and Efficiency in Automobile

V12 Engine: Unleashing Ultimate Power, Performance, and Luxury