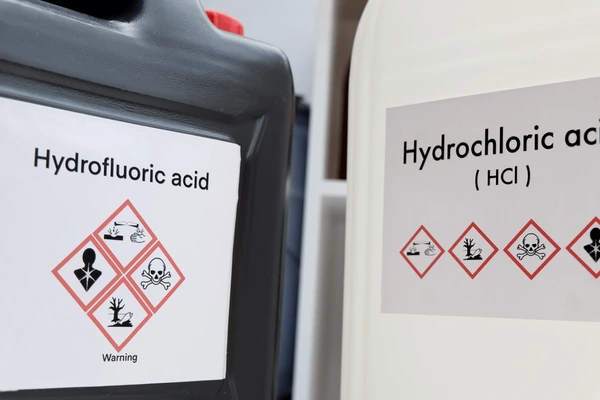

What is Hydrofluoric Acid?

Hydrofluoric acid (HF) is a highly potent inorganic acid composed of hydrogen and fluoride atoms. It exists as a diatomic molecule in its gaseous state and forms strong hydrogen bonds in its liquid state, resulting in a polymeric structure. HF is known for its extreme corrosiveness and ability to dissolve various materials, particularly oxides. It has a boiling point of 20°C (68°F) at 760 mmHg and a vapor density greater than air. When diluted in water, it undergoes an exothermic reaction and becomes visually indistinguishable from water.

How is Hydrofluoric Acid Made?

The primary method of producing hydrofluoric acid involves treating fluorite (calcium fluoride) with concentrated sulfuric acid at temperatures around 265°F, resulting in hydrofluoric acid and calcium sulfate. An alternative production method is as a by-product in the production of phosphoric acid from the mineral apatite. Additionally, HF can be released from industrial and welding processes, as well as environmental activities such as volcanic eruptions.

Properties of Hydrofluoric Acid

Chemical Properties

- Reactivity: Hydrofluoric acid is highly reactive, particularly with oxides of metals such as alkali, alkali earth metals, lead, zinc, and silver, as well as hydroxides and carbonates, forming fluorides. This reactivity is leveraged in applications such as metal cleaning and etching.

- Corrosiveness: HF is extremely corrosive and can dissolve many materials, especially oxides. This property is utilized in glass etching and cleaning applications.

- Toxicity: HF is highly toxic and can cause severe burns upon contact with skin, penetrating deeply and causing tissue damage. It requires careful handling and appropriate safety measures.

Physical Properties

- Appearance: Hydrofluoric acid is a colorless, pungent liquid that fumes in air. It can range from colorless to slightly tinted based on concentration and impurities.

- Boiling Point: HF has a boiling point of 20°C (68°F) at 760 mmHg, which is relatively low compared to other acids.

- Surface Tension and Penetration: HF has a small surface tension and strong penetration ability, allowing it to penetrate skin and mucous membranes easily.

- Hydrogen Bonding: In its liquid state, HF forms strong hydrogen bonds, creating a polymeric structure. This contributes to its unique physical properties.

Safety Hazards of Hydrofluoric Acid

- Skin and Tissue Damage: HF penetrates deep into tissues, causing destruction of deep tissue layers and even bones. Burns from HF can be life-threatening and require immediate medical attention, often involving the application of calcium gluconate to neutralize the fluoride ions.

- Respiratory and Cardiac Issues: Inhalation of HF fumes can lead to severe respiratory distress and cardiac complications, including ventricular arrhythmia and ventricular fibrillation.

- Bioaccumulation: Long-term exposure to HF can lead to bioaccumulation in human tissues, causing serious health problems such as bone embrittlement.

- Environmental Hazards: HF is highly toxic to the environment, with potential long-lasting harmful effects on water organisms and ecosystems.

Handling and Safety Precautions

- Personal Protective Equipment (PPE): Workers should wear appropriate PPE, including acid-resistant gloves, face shields, and protective clothing, to prevent skin and eye contact with HF.

- Emergency Response: Facilities using HF should have emergency response plans in place, including gas leak alarms, infrared cameras, and CCTVs to detect and respond to HF leaks promptly. Immediate washing with water and application of calcium gluconate gel are critical first-aid measures for HF skin exposure.

- Engineering Controls: Use of reaction chambers or electrochemical etching apparatus designed to minimize operator contact with HF solutions is recommended. Proper ventilation and fume hoods are also essential to prevent inhalation of HF fumes.

- Training and Awareness: Workers should be trained on the hazards of HF and the correct use of PPE and emergency response procedures. Regular drills and safety audits can help ensure preparedness for HF-related incidents.

Environmental Impact of Hydrofluoric Acid

HF poses significant environmental risks due to its high toxicity and corrosiveness. It can cause severe environmental damage if released into the atmosphere or water bodies. HF is a potent greenhouse gas and contributes to global warming. Additionally, HF emissions from industrial processes can lead to air and water pollution, affecting both human health and ecosystems. Efforts to reduce the environmental impact of HF include developing safer alternatives and reducing the fluorine content in industrial processes.

Applications of Hydrofluoric Acid

Industrial Applications

- Aluminum Production: HF plays a crucial role in aluminum production by producing aluminum fluoride, which is essential for aluminum extraction.

- Stainless Steel Manufacturing: It is used in the pickling process to remove oxides and impurities from stainless steel surfaces.

- Glass Etching: HF etches and frosts glass surfaces, allowing for intricate designs and patterns with precision.

- Petroleum Refining: HF serves as a catalyst in the alkylation process for producing high-octane gasoline in the petroleum industry.

- Chemical Manufacturing: It serves as a precursor in the production of various fluorine-containing compounds, including refrigerants and pharmaceuticals.

Consumer Products

- Rust Removers and Cleaners: HF helps dissolve oxides in rust removers and cleaning agents for marble, brick, and stone.

- Automobile Cleaners: HF works effectively in specialized cleaners for automobile wheels and air conditioners, removing grime and buildup.

- Insecticides: HF is an active ingredient in certain insecticides, leveraging its chemical properties to eliminate pests.

Latest Technical Innovations in Hydrofluoric Acid

Preparation and Purification Technologies

- Electronic Grade Hydrofluoric Acid: Recent advancements focus on the preparation and purification of electronic grade hydrofluoric acid, which is crucial for semiconductor and integrated circuit cleaning. The development of advanced technologies in this area is essential to reduce dependence on imports and promote the growth of the fluorine chemical industry in China.

- Dilution Methods: Innovations include methods for producing diluted hydrofluoric acid using an electrode arrangement with an anion exchange membrane. This method allows for precise control of the concentration of hydrofluoric acid, even at low and ultralow levels, enhancing workplace safety and accuracy in production.

Safety Enhancements

- Handling and Storage: Research has highlighted the importance of safety measures in the usage and storage of hydrofluoric acid and its derivatives. Innovations in this area aim to increase user protection and reduce accidental damage and environmental impact by improving the understanding of the physical and chemical properties of hydrofluoric acid2.

Technological Developments

- Electrode Arrangement for Dilution: A novel method involves using an electrode arrangement with an anode and cathode chamber separated by an anion exchange membrane. Pure water and an electrolyte solution containing fluoride ions are passed through these chambers, and an electrical voltage is applied to move the fluoride ions into the anode chamber, resulting in a precisely diluted hydrofluoric acid solution.

- Supporting Technologies: The development of supporting technologies for the preparation and purification of electronic grade hydrofluoric acid is crucial. These technologies include advanced purification processes and the integration of supporting systems to enhance the overall efficiency and quality of hydrofluoric acid production.

Environmental Impact Reduction

- Innovative Production Methods: New methods focus on reducing the environmental impact of hydrofluoric acid production. These include the development of more efficient and environmentally friendly production processes, as well as the implementation of advanced purification technologies to minimize waste and emissions.

Future Prospects

- Research and Development: Continuous research and development are essential to further improve the preparation, purification, and handling of hydrofluoric acid. Future innovations are expected to focus on enhancing the safety, efficiency, and environmental sustainability of hydrofluoric acid production and usage.

To get detailed scientific explanations of hydrofluoric acid, try Patsnap Eureka.

Learn more

Ammonium Hydroxide: A Closer Look at This Ammonia Solution

Pressure Switches: Small Devices, Big Impact

Unveiling The Lead Screw: Its Mechanism, Benefits, And Beyond