Introduction

A Ferrari engine is more than just a powerhouse—it’s the soul of every Ferrari vehicle. Crafted with precision and passion, these engines deliver unmatched performance and a driving experience that captivates enthusiasts worldwide. From high-revving V8s to prestigious V12s and cutting-edge hybrids, Ferrari engines embody a legacy of innovation and racing excellence. Let’s explore what makes these engines iconic, their history, and their contribution to automotive performance.

History of Ferrari Engine Development

Early Years and Foundational Technologies

Ferrari’s engine journey began in the late 1940s with the 125 S, its first car. Featuring a 1.5-liter V12 designed by Gioachino Colombo, it set the stage for Ferrari’s signature engine design. The V12 quickly became a Ferrari hallmark, delivering smooth power and high performance.

Evolution of V12 Engines

In the 1950s and 1960s, Ferrari refined its V12 engines, increasing displacement and adopting advanced materials. The legendary 3.0-liter V12 in the 250 GTO set new standards in power, efficiency, and racing success, solidifying Ferrari’s dominance.

Turbocharging Innovation

In the 1980s, Ferrari embraced turbocharging to achieve greater performance. Models like the 288 GTO and F40 featured turbocharged V8 engines that delivered unprecedented power and acceleration while maintaining efficiency and reliability.

Advancements in Engine Control

By the 1990s and 2000s, Ferrari introduced advanced electronic control units (ECUs) to optimize fuel injection and ignition timing. These innovations improved performance, fuel efficiency, and emissions. The Ferrari 360 Modena’s 3.6-liter V8 showcased this technology with enhanced drivability and power.

Hybrid and Electric Technologies

In the 2010s, Ferrari adopted hybrid systems to meet performance and environmental demands. The LaFerrari combined a 6.3-liter V12 with an electric motor, using its HY-KERS system to boost power and fuel efficiency. This marked Ferrari’s shift toward innovation and sustainability.

Hybrid and Electric Technologies

In recent years, Ferrari has embraced hybrid and electric technologies to meet evolving regulatory requirements and enhance performance. The LaFerrari, introduced in 2013, featured a hybrid powertrain combining a 6.3-liter V12 engine with an electric motor. This hybrid system, known as HY-KERS, provided additional power and improved fuel efficiency, showcasing Ferrari’s commitment to innovation and sustainability.

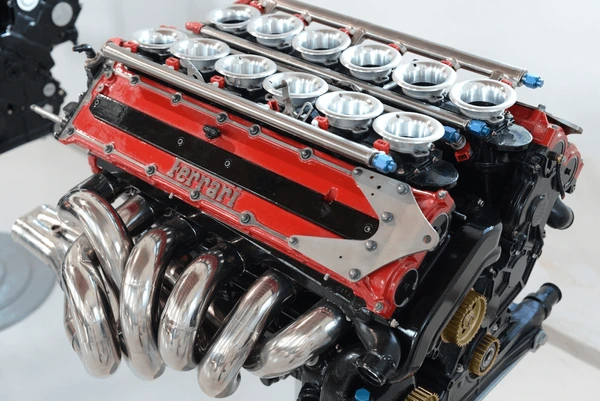

Types of Ferrari Engines

- V12 Engines: The Ferrari F140 series, including the F140 B engine used in the Enzo Ferrari, is a notable example. This engine is known for its high performance, bridging the gap between Ferrari’s racing engines and those used in their production cars1.

- V8 Engines: Ferrari’s V8 engines, such as those found in the 488 GTB, are celebrated for their balance of power and efficiency. These engines often feature turbocharging to enhance performance.

- V6 Engines: The newer V6 engines, like those in the Ferrari 296 GTB, incorporate hybrid technology to deliver impressive power while improving fuel efficiency and reducing emissions.

Key Features of Ferrari Engines

High-Performance Engineering

Ferrari engines are renowned for their high-revving capabilities, often exceeding 8,000 RPM. This is achieved through meticulous engineering of the engine components, including lightweight materials and precision balancing of the crankshaft and pistons. The use of advanced materials such as titanium and carbon fiber helps reduce the overall weight of the engine, contributing to its high performance.

Variable Valve Timing and Lift

Ferrari employs sophisticated variable valve timing and lift systems, such as the Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies. These systems optimize the engine’s performance across different RPM ranges by adjusting the timing and lift of the intake and exhaust valves, ensuring maximum power output and efficiency.

Turbocharging and Supercharging

Modern Ferrari engines often incorporate turbocharging and supercharging technologies to enhance power output without significantly increasing engine displacement. This allows for a more compact engine design while still delivering exceptional performance. The integration of these technologies is carefully calibrated to minimize turbo lag and provide a seamless power delivery.

Direct Fuel Injection

Ferrari engines utilize direct fuel injection systems that deliver fuel directly into the combustion chamber at high pressure. This improves fuel atomization and combustion efficiency, resulting in higher power output and better fuel economy. The precise control of fuel injection also helps reduce emissions.

Advantages and Disadvantages of Ferrari Engines

Advantages of Ferrari Engines

- Exceptional Performance: Ferrari engines are designed to deliver outstanding performance, with high horsepower and torque figures. For example, the Ferrari 488 GTB’s 3.9-liter V8 engine produces 661 horsepower and 561 lb-ft of torque, allowing it to accelerate from 0 to 60 mph in just 3 seconds.

- Advanced Aerodynamics and Cooling: The design of Ferrari engines is complemented by advanced aerodynamics and cooling systems. These systems ensure that the engine operates at optimal temperatures even under extreme conditions, enhancing reliability and performance.

- Innovative Engineering Solutions: Ferrari continuously invests in research and development to incorporate cutting-edge technologies into their engines. This includes the use of hybrid systems, as seen in the LaFerrari, which combines a V12 engine with an electric motor to deliver a combined output of 950 horsepower.

Disadvantages of Ferrari Engines

- High Maintenance Costs: The advanced technologies and materials used in Ferrari engines result in high maintenance and repair costs. Regular servicing by specialized technicians is required to ensure the engine remains in peak condition, which can be expensive.

- Complexity and Reliability Issues: The complexity of Ferrari engines, with their numerous advanced systems and components, can sometimes lead to reliability issues. The high-performance nature of these engines means they are subjected to significant stress, which can result in more frequent breakdowns and the need for repairs.

- Fuel Consumption and Emissions: Despite advancements in fuel injection and turbocharging, Ferrari engines are still relatively fuel-hungry compared to more conventional engines. This can result in higher fuel costs and increased emissions, which may be a concern for environmentally conscious consumers.

Comparison with Other High-Performance Engines

- Versus Maserati: Ferrari’s V12 engines, such as those used in the Enzo, offer higher performance and a more distinctive sound compared to Maserati’s V8 engines. However, Maserati engines may offer better fuel efficiency and lower maintenance costs.

- Versus Hybrid Systems: Compared to hybrid high-performance engines, Ferrari’s traditional internal combustion engines may lag in terms of fuel efficiency and emissions. Hybrid systems, like those proposed in recent patents, offer significant improvements in these areas by combining multiple power sources and optimizing power transfer.

- Versus Opposed-Piston Engines: Opposed-piston engines, as described in some patents, offer advantages in terms of weight reduction and efficiency. These engines eliminate certain mechanical losses and can be more compact, which may provide performance benefits in specific applications.

Applications of Ferrari Engine

Automotive Applications

- Sports Cars: Ferrari engines are the heart of Ferrari’s sports car lineup, providing exceptional power, speed, and driving dynamics. For instance, the Ferrari 488 GTB is powered by a 3.9-liter twin-turbo V8 engine that produces 661 horsepower and 561 lb-ft of torque, enabling a 0-60 mph time of just 3.0 seconds.

- Racing: Ferrari engines are extensively used in motorsports, particularly in Formula 1. The Ferrari SF21, used in the 2021 Formula 1 season, features a 1.6-liter V6 turbo hybrid engine that delivers over 1000 horsepower, showcasing Ferrari’s commitment to innovation and performance in competitive racing environments.

Non-Automotive Applications

- Marine: Ferrari engines can be adapted for use in high-performance marine vessels. Their high power-to-weight ratio and reliability make them suitable for luxury yachts and speedboats, where performance and prestige are paramount.

- Aerospace: Although less common, the principles and technologies used in Ferrari engines can inspire aerospace applications, particularly in the development of lightweight, high-performance propulsion systems for small aircraft or drones.

Latest Technical Innovations in Ferrari Engine

Advanced Combustion Technologies

Ferrari has been at the forefront of adopting advanced combustion technologies to enhance engine efficiency and performance. One notable innovation is the use of Turbulent Jet Ignition (TJI). This technology improves the combustion process by creating a more homogeneous air-fuel mixture, leading to higher thermal efficiency and reduced emissions. The TJI system allows for leaner combustion, which translates to better fuel economy and lower CO2 emissions.

Hybrid Powertrains

Ferrari has integrated hybrid powertrains into its latest models, such as the SF90 Stradale. The hybrid system combines a traditional internal combustion engine (ICE) with electric motors, providing several benefits:

- Increased Power Output: The combination of ICE and electric motors results in a significant boost in power. For instance, the SF90 Stradale delivers a combined output of 986 horsepower.

- Improved Fuel Efficiency: The hybrid system allows for regenerative braking and electric-only driving modes, reducing fuel consumption during urban driving.

- Enhanced Performance: Instant torque from electric motors improves acceleration and overall driving dynamics.

Lightweight Materials and Engine Components

Ferrari has been utilizing advanced lightweight materials to reduce the overall weight of the engine and the vehicle. The use of carbon fiber composites and aluminum alloys in engine components such as the cylinder block and heads helps in achieving a better power-to-weight ratio. This not only enhances performance but also contributes to better fuel efficiency and handling.

Variable Valve Timing and Lift Systems

The implementation of Variable Valve Timing (VVT) and Variable Valve Lift (VVL) systems in Ferrari engines allows for optimized engine breathing across different RPM ranges. This technology adjusts the timing and lift of the intake and exhaust valves, leading to:

- Improved Power Delivery: Enhanced torque and power output at both low and high RPMs.

- Better Fuel Efficiency: Optimized valve timing reduces pumping losses and improves combustion efficiency.

- Reduced Emissions: More precise control of the air-fuel mixture results in cleaner combustion.

Turbocharging and Forced Induction

Ferrari has embraced turbocharging to increase engine performance without significantly increasing engine displacement. The use of twin-scroll turbochargers and electric turbochargers has several advantages:

- Higher Power Output: Turbocharging increases the amount of air entering the engine, allowing for more fuel to be burned and thus more power to be generated.

- Improved Efficiency: Modern turbochargers are designed to minimize lag and maximize efficiency, providing better fuel economy.

- Enhanced Performance: Turbocharged engines offer superior performance characteristics, such as increased torque and faster acceleration.

To get detailed scientific explanations of Ferrari Engine, try Patsnap Eureka.

Learn More

2024 Toyota Hilux Review: Everything You Need to Know

The LS3 Engine: Unleashing Power and Efficiency in Automobile

V12 Engine: Unleashing Ultimate Power, Performance, and Luxury