What is a Dual Clutch Transmission?

A Dual Clutch Transmission (DCT) is a cutting-edge type of automatic transmission designed for optimal performance and efficiency. By utilizing two separate clutches for odd and even gear sets, it ensures seamless gear shifts without disrupting power flow from the engine to the wheels. This innovative design not only enhances driving performance but also improves fuel efficiency, making it a popular choice in modern vehicles. This article will explore how DCT works, its benefits, and its applications in the automotive industry.

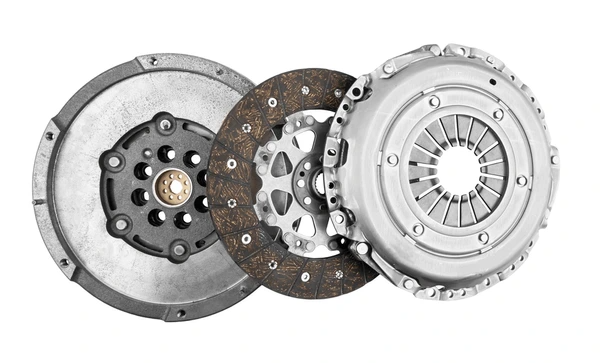

How Does a Dual Clutch Transmission Work?

The operation of a DCT relies on two clutches working together to enable smooth and uninterrupted gear shifts. When the vehicle engages first gear, the first clutch connects while the second clutch prepares the next gear. During a shift, the first clutch releases, and the second clutch engages, ensuring a seamless gear change. This cycle continues through subsequent gears, maintaining consistent power delivery and enhancing acceleration. An actuator, driven by a pressure medium, controls the clutches by using pressure generated from a compressor.

Types of Dual Clutch Transmissions

- Wet Multi-Plate Clutches: These clutches operate in an oil bath, which reduces wear and provides effective cooling. Their durable design makes them ideal for handling high-torque applications, ensuring smooth gear engagement. However, they may cause increased pumping losses due to the transmission fluid involved.

- Dry Single-Plate Clutches: These clutches operate without oil, making them a better fit for lower torque applications. They enhance fuel efficiency by eliminating fluid pumping losses, although they might produce more noise and have reduced durability compared to wet clutches.

Benefits of Dual Clutch Transmissions

- Enhanced Energy Efficiency:

DCTs improve energy efficiency compared to traditional systems by filling torque gaps during shifts for smoother acceleration. They deliver up to 15% better fuel economy than planetary transmissions and surpass manual transmissions in efficiency. - Improved Performance and Driving Experience:

DCTs offer sporty performance with fast, smooth gear changes that mimic manual systems. They ensure seamless power delivery, enhancing acceleration and driving dynamics. - Fuel Economy and Environmental Benefits:

With efficient gear meshing and reduced clutch losses, DCTs achieve better fuel economy. Their design lowers fuel consumption and emissions, supporting eco-friendly vehicles. - Versatility and Adaptability:

DCTs suit a wide range of engines, from high-torque diesels to revving gasoline options. They integrate well with hybrid systems, boosting efficiency. - Advanced Control Systems:

Sophisticated hydraulic and electronic systems manage DCTs precisely. Active flow regulators and actuators ensure reliable clutch engagement and gear shifts. - Compact and Lightweight Design:

Engineers design DCTs for reduced size and weight, improving mountability. Simplifying components enhances vehicle handling and overall performance. - Reliability and Durability:

Enhanced friction elements and advanced fluids help DCTs achieve millions of shifts. They maintain launch quality and durability over time. - Reduced Maintenance and Operational Costs:

Automatic wear compensation in DCTs minimizes maintenance needs. Electro-mechanical clutch actuators further reduce costs and improve long-term reliability.

Dual Clutch vs. Automatic Transmission

Performance and Efficiency

DCTs outperform traditional systems by offering up to 15% better fuel efficiency compared to planetary-ATs. They achieve this through dual wet clutches and advanced electrohydraulic controls. These features ensure quick clutch engagement, improved controllability, and seamless operation under slipping conditions. DCTs also support faster acceleration and higher top speeds than ATs and CVTs.

Shift Quality and Driving Experience:

DCTs provide smooth, uninterrupted shifts that eliminate the power loss typical in traditional gear changes. By engaging two clutches simultaneously, they deliver seamless power transitions during gear shifts. Advanced control methods ensure rapid and smooth gear changes, enhancing ride comfort. The dual clutch system allows continuous power during upshifts and downshifts, creating a superior driving experience.

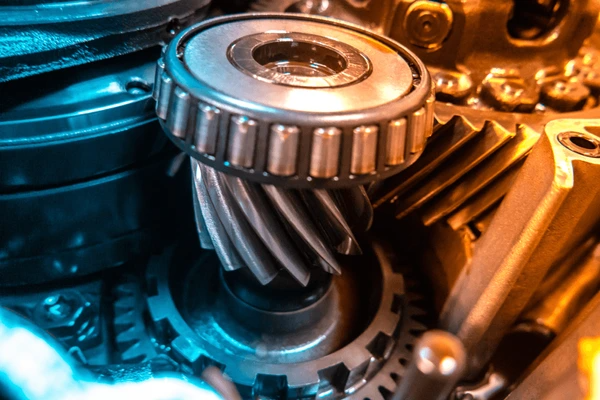

Structural and Operational Differences:

DCTs use two clutches and two input shafts, enabling faster and smoother gear changes. This setup pre-selects the next gear while the current gear remains engaged. Unlike ATs, which rely on a single clutch and torque converter, DCTs provide more efficient and rapid shifts. The dual clutch mechanism, often featuring dry disc clutches, allows independent control of each clutch through dedicated actuators.

Control Systems and Technologies:

DCTs employ sophisticated control systems like μC/OS-II, ensuring real-time responses and reliable performance. Advanced technologies measure rotary speed, gear position, and clutch pressure, optimizing precision and reliability. These systems integrate into mechatronic modules, minimizing tolerance variations and enabling fast, accurate clutch control.

Maintenance and Longevity:

DCTs are built for durability, capable of more than two million shifts per clutch. Enhanced friction materials and advanced transmission fluids improve reliability and reduce wear. Their design also supports controlled slipping, minimizing component stress. ATs, in contrast, may demand more frequent maintenance due to hydraulic complexities and potential torque converter issues.

Application and Market Potential:

DCTs excel across vehicle types, from high-torque diesel engines to high-revving gasoline engines. Their fuel efficiency and superior driving experience make them popular in mainstream markets. With growing demand for better power performance and shift quality, DCTs hold significant promise in the future of automotive transmissions.

Common Issues with Dual Clutch Transmissions and Solutions

Performance and Efficiency

- DCTs: Dual Clutch Transmissions provide up to 15% better fuel efficiency than traditional automatic systems. Their dual wet clutch design and electrohydraulic control maintain uninterrupted power flow during gear shifts, enhancing both acceleration and top speed. These features make DCTs highly efficient and performance-oriented.

- ATs: Automatic transmissions rely on torque converters, which can cause higher energy losses during gear changes. Although they provide smooth operation, their slower gear transitions and inefficiencies often lead to reduced acceleration and fuel economy compared to DCTs.

Shift Quality and Driving Experience

- DCTs: DCTs ensure seamless gear changes by pre-selecting gears and enabling uninterrupted power delivery during shifts. This precision enhances the overall driving experience by providing quick and smooth transitions, making the ride more dynamic and responsive.

- ATs: ATs offer a comfortable driving experience but often introduce noticeable interruptions in power flow during gear shifts. These delays can impact responsiveness and reduce the overall satisfaction of driving performance-focused vehicles.

Structural and Operational Differences

- DCTs: DCTs use two clutches and input shafts, allowing one gear to be pre-selected while another is engaged. This design results in faster, smoother shifts and more efficient power delivery. Their construction typically includes dedicated actuators for precise clutch control.

- ATs: ATs operate with a single clutch and torque converter, relying on planetary gear sets and hydraulic systems. This setup leads to slower shifts and less efficient power transfer, making them less dynamic than their dual-clutch counterparts.

Control Systems and Technologies

- DCTs: Advanced control systems in DCTs incorporate real-time technologies like μC/OS-II, optimizing clutch pressure and gear transitions. These systems integrate sensor data to ensure fast, precise, and reliable operation under varying conditions.

- ATs: ATs depend on hydraulic controls for gear management, which can be less precise than electronic systems in DCTs. Despite recent advancements, their response time and shift accuracy often fall behind the capabilities of DCT technologies.

Maintenance and Longevity

- DCTs: DCTs are designed for durability, with improved friction materials and transmission fluids supporting millions of shifts. Their reduced wear and advanced design result in lower maintenance requirements over their operational lifespan.

- ATs: ATs often require more frequent maintenance due to the complexity of their hydraulic systems and the wear-prone nature of torque converters. Long-term performance may decline without regular servicing.

Application and Market Potential

- DCTs: DCTs excel in a variety of vehicles, offering superior performance for both high-torque diesel engines and sporty gasoline models. Their adaptability and fuel efficiency make them a compelling choice for modern vehicles across different market segments.

- ATs: ATs are popular for their simplicity and ease of use, making them suitable for everyday drivers. However, they typically lack the advanced performance, efficiency, and market adaptability seen in DCTs.

Applications of Dual Clutch Transmission

Automotive Industry

DCTs play a critical role in the automotive sector by delivering smooth gear shifts without power loss. These systems improve fuel efficiency and driving performance, making them ideal for high-performance and luxury vehicles. Popular in sports cars, DCTs enhance acceleration, provide seamless shifting, and contribute to better fuel economy. For instance, Volkswagen’s 7-speed DSG gearbox exemplifies the efficiency and adaptability of these systems in everyday vehicles.

Electric Vehicles (EVs)

In EVs, DCTs enhance torque transmission and ensure smoother gear shifts, improving overall vehicle performance. A novel magneto-rheological fluid clutch design offers precise control and faster response for two-speed EV transmissions. This innovation reduces torque interruptions, significantly enhancing both efficiency and the driving experience in electric vehicles.

Medium-Duty Trucks

DCTs are increasingly used in medium-duty trucks to eliminate torque interruptions during gear shifts. These systems ensure smoother shifts, similar to automatic transmissions, for better driving dynamics. Research shows DCTs avoid engine flaring, improving driveline efficiency and offering a cost-effective solution for medium-duty trucks.

Agricultural Tractors

DCTs provide uninterrupted power delivery in tractors, essential for maintaining performance in varying field conditions. The system includes two input shafts connected by clutches to the main drive shaft, ensuring seamless torque transfer. This design supports consistent power transmission, critical for demanding agricultural operations.

Hybrid Vehicles

In hybrid vehicles, DCTs enable efficient power integration by allowing electric motors to engage directly with the transmission. The dual-clutch setup also separates the internal combustion engine when needed, ensuring smooth hybrid operation. This configuration enhances fuel efficiency while delivering superior performance in hybrid systems.

Control Systems and Real-Time Applications

DCTs rely on advanced control models for precise and efficient gear shifting. Control-oriented models simulate hydraulic dynamics, ensuring real-time responsiveness and accuracy. These models use fuzzy logic to manage complex operations, providing automatic pressure control for smooth and consistent clutch engagement.

Cooling and Lubrication Systems

Efficient cooling and lubrication are vital for DCTs to handle varying heat generation and maintain reliability. Advanced systems regulate clutch cooling independently, optimizing performance under diverse conditions. Specialized DCT fluids improve friction performance and thermal stability, enhancing durability and efficiency.

Real-Time Simulation and HIL Applications

Real-time simulation models are essential for validating DCT control strategies in realistic scenarios. These models incorporate hydraulic and servo dynamics, ensuring accurate and stable testing. Hardware-in-the-loop applications use these simulations to refine performance and improve system reliability.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Dual Clutch Transmission Apparatus Aisin Ai Co., Ltd. | Reduces transmission efficiency loss and improves overall performance. | Automotive industry, particularly in vehicles requiring efficient power transmission. |

| Dual Clutch Transmission Mercedes-Benz Group AG | Provides seamless gear shifts without power interruption, enhancing driving performance. | High-performance sports cars and luxury vehicles. |

| Hydraulic Transformer Clutches A&A International LLC | Enables controlled power transfer with high precision. | Automotive applications requiring precise power control. |

| Magneto-Rheological Fluid Dual-Clutch Design University of Wollongong | Combines DCT and MRF clutch advantages for precise control and fast response. | Electric vehicles to improve torque transmission and shifting comfort. |

| Dual Clutch Transmission with Chain Drive GM Global Technology Operations LLC | Provides efficient torque transmission and multiple gear options. | Automotive powertrain systems, enhancing vehicle performance and efficiency. |

Latest Technical Innovations in Dual Clutch Transmission

Structural Improvements

- Compact Design and Mountability: Recent DCT innovations focus on reducing weight and length by optimizing synchronizers and external gears. Simplified designs improve integration across various vehicle types and lower production costs. The placement of the drive motor has also been refined for better mountability, enhancing versatility in automotive applications.

- New Transmission Configurations: A novel DCT design uses a split dual-clutch assembly with countershaft gearing and a planetary gear set. This configuration offers at least thirteen forward gear ratios, improving performance and fuel efficiency. It is especially suitable for commercial vehicles and heavy-duty trucks due to its enhanced shifting capabilities.

Control Systems

- Fuzzy Logic Control: Advanced fuzzy logic methods manage the complex non-linear behavior of DCTs, improving shift quality and clutch engagement. These systems map throttle input and vehicle speed to optimize shift timing and pressure demands. This intelligent control enhances the precision and future scalability of DCT technology.

- Hydraulic Control Systems: Modern hydraulic systems reduce weight and prevent pressure fluctuations caused by centrifugal forces or accidental activations. These systems feature compensation chambers that stabilize hydraulic pressure, increasing efficiency and responsiveness. This improvement simplifies the design while ensuring better control and reliability.

Materials and Fluids

- Advanced Transmission Fluids: Specialized fluids like GEELY-DCTF improve clutch friction performance and thermal stability, meeting the stringent demands of modern DCTs. These fluids also enhance anti-corrosion, anti-foaming, and shear stability, ensuring long-term durability under high-performance conditions.

Performance Enhancements

- Improved Shift Quality and Efficiency: Modern DCTs achieve smoother shifts by eliminating acceleration pauses typical in single disc clutches. Controllers manage clutch and shift actuators, enabling precise gear changes and skip shifts, such as 6-to-3 or 5-to-2 transitions. This technology enhances the driving experience by maintaining seamless power delivery.

- Noise and Vibration Reduction: Advanced dual-clutch designs focus on minimizing noise and vibration while improving torque transfer and assembly ease. These designs use actuators to compress friction elements, enhancing transmission efficiency and extending durability.

- Dry Dual Clutch Technology: Volkswagen’s seven-speed DSG transmission incorporates a dry dual-clutch system, which increases efficiency while reducing fuel consumption and emissions. This innovation is particularly effective for compact and small vehicles, where lightweight and fuel efficiency are critical.

To get detailed scientific explanations of Dual Clutch Transmission, try Patsnap Eureka.