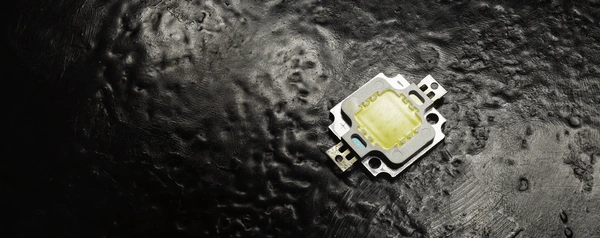

What Is a COB LED?

A COB LED (Chip-on-Board LED) is an array of LED chips mounted directly on a substrate, typically a printed circuit board (PCB) or a ceramic substrate. The chips are electrically connected in series or parallel, and the entire array is encapsulated with a protective material, such as silicone or epoxy resin.

Key Components of a COB LED

- Substrate: A ceramic or metal-core PCB (MCPCB) substrate with high thermal conductivity for efficient heat dissipation.

- LED Chips: Multiple LED chips of different colors (red, green, blue, etc.) are arranged in an array on the substrate.

- Conductive Traces: Conductive traces or wires on the substrate electrically connect the LED chips in series or parallel configurations.

- Encapsulation: A phosphor-containing silicone or epoxy encapsulant is dispensed over the LED chips to provide color conversion and protection.

How COB LEDs Work

- LED Chip Excitation: The LED chips, typically made of gallium nitride (GaN) or indium gallium nitride (InGaN), are electrically excited by applying a forward voltage across their p-n junctions.

- Blue Light Emission: The excited LED chips emit high-energy blue light through the principle of electroluminescence.

- Phosphor Conversion: The blue light from the LED chips is partially or fully absorbed by phosphor materials (e.g., yttrium aluminum garnet) coated on or surrounding the chips.

- Photoluminescence: The absorbed blue light excites the phosphor materials, which then re-emit light at longer wavelengths (e.g., yellow, green, or red) through the process of photoluminescence.

- Color Mixing: The remaining blue light from the LED chips and the photoluminescence light from the phosphors are mixed to produce the desired white light or colored light output

Key Features of COB LEDs

- High Packing Density and Uniform Light Emission: COB LEDs achieve high chip density, creating an extended light source with higher intensity and uniform emission compared to point sources.

- Thermal Management Challenges: Compact designs concentrate heat in COB LEDs, requiring efficient thermal management to prevent overheating and maintain performance.

- Color Tuning and Beam Control: COB LEDs adjust color temperature and beam shape by selectively activating segments with varying colors or temperatures.

- Simplified Manufacturing Process: Integrated packaging simplifies COB LED production, reducing costs and streamlining the workflow compared to traditional methods.

- Optical Efficiency Optimization: High refractive index encapsulants, dome shapes, and reflective components enhance light extraction and efficiency in COB LEDs.

Advantages of COB LEDs

- High Pixel Density and Brightness: COB LEDs pack more chips on a single substrate, delivering higher intensity and uniform light for vivid images.

- Compact and Thin Design: Their integration enables ultra-thin displays, combining multiple LED chips into a compact, sleek form factor.

- Improved Thermal Management: Direct chip mounting on substrates enhances heat dissipation, boosting reliability and extending LED lifespan.

- Cost-Effective Manufacturing: By eliminating individual LED packaging, COB simplifies production and reduces material costs compared to traditional methods.

Challenges of COB LEDs

- Color Mixing and Uniformity: Ensuring consistent color mixing and rendering across the COB surface is challenging, especially with smaller pixel pitches.

- Beam Control and Optical Design: Achieving precise beam patterns requires advanced optics due to the high chip density and complex light distribution.

- Heat Dissipation at High Power Densities: Managing heat effectively in compact, high-power COB designs remains difficult, impacting efficiency and lifespan.

- Color Tuning and Dimming Complexity: Controlling multiple LED channels for precise tuning and dimming demands sophisticated systems and algorithms.

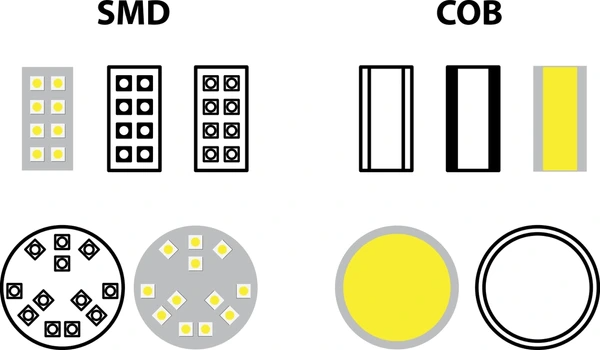

COB LEDs vs. SMD LEDs

Packaging Structure

SMD (Surface Mount Device) LEDs package LED chips in a small plastic casing, suitable for low-power applications but with poor heat dissipation. 3 COB (Chip on Board) LEDs directly package multiple LED chips on the same substrate, offering better heat dissipation for high-power LED sources.

Heat Dissipation

The high chip density in COB LEDs leads to localized heat buildup, which can accelerate device aging, cause light decay, and color shift if not properly dissipated. Effective heat dissipation is crucial for maintaining COB LED performance and lifespan. 10 COB LEDs have a lower thermal resistance path (chip-adhesive-substrate) compared to SMD LEDs, significantly improving lifespan.

Optical Performance

COB LEDs appear as a uniform light panel, while closely packed SMD LEDs may exhibit pixelated light spots and glare issues. 11 COB LEDs with hemispherical phosphor layers enhance light efficiency by 11.74% (4000K) and 14.52% (5000K) compared to flat phosphor layers.

Packaging Process

SMD LEDs undergo a multi-step packaging process (die attach, wire bonding, encapsulation) before being mounted on PCBs by manufacturers. COB LEDs directly bond chips to PCBs, simplifying the process and reducing costs.

Applications

SMD LEDs are suitable for general lighting without beam angle requirements. COB LEDs excel in applications needing high lumen density and anti-glare performance, like commercial lighting. COB LEDs enable higher pixel densities for mini/micro LED displays compared to SMD LEDs.

Applications of COB LED

General Lighting Applications

- Backlighting for displays: COB LEDs are widely used as backlights for LCD displays in various applications, including TVs, monitors, laptops, tablets, and automotive displays . Their compact size, high brightness, and uniform illumination make them ideal for this purpose.

- General illumination: COB LEDs are employed in various general lighting applications, such as downlights, spotlights, and street lights, due to their high efficacy, long lifespan, and energy efficiency.

Specialized Lighting Applications

- Automotive Lighting: COB LEDs are widely adopted in headlights, taillights, and interior lighting due to their compactness, durability, and brightness.

- Horticultural Lighting: COB LEDs enable customizable spectral outputs, making them ideal for optimizing plant growth in horticultural applications.

- Medical and Scientific Applications: High-intensity and precise spectral control make COB LEDs valuable for surgical lighting, microscopy, and analytical instruments.

Emerging Applications

- Visible Light Communications (VLC): COB LEDs support high-frequency modulation, making them suitable for data transmission in visible light communication systems.

- Ultraviolet (UV) Curing: UV-emitting COB LEDs excel in curing coatings, adhesives, and inks, offering efficient alternatives to traditional UV sources.

- Infrared (IR) Applications: IR-emitting COB LEDs are utilized in night vision systems, surveillance cameras, and infrared heating applications

Latest Technical Innovations in COB LED

Light Extraction Efficiency Improvements

Optimizing silicone encapsulant usage in COB LEDs enhances light extraction efficiency, luminous flux, and CRI while achieving tailored optical distributions. For instance, a 14W white COB LED with a 4900K color temperature, CRI of 82, and luminous efficiency of 125 lm/W at 30 A/cm² was realized using advanced encapsulation techniques.

Structural Innovations

Novel COB LED packaging structures have been developed to enhance light output and ease of manufacturing:

- Structures with through-holes acting as reflector cups to improve light extraction efficiency and facilitate precise phosphor gel dispensing

- Stepped chip mounting surfaces with blue and red LED chips mounted at different heights to minimize optical interference and improve color rendering

- Transparent gel coatings with high refractive index for improved light uniformity

Multi-Color Integration

To achieve tunable color temperatures and improve color rendering, COB LEDs integrating blue, green, and red LED chips have been developed. This allows for a single light source with multiple applications and the ability to correct color shifts over time.

Thermal Management Innovations

Effective thermal management is crucial for high-power COB LEDs. Innovations include:

- Single-unit cooling fin aluminum flat heat pipes for compact, socket-type 100W COB LED lamps

- Embedded heat pipes in metal-core printed circuit boards (MCPCBs)

- Liquid cooling systems to maintain junction temperatures below 125°C

Electrical Configurations

Novel electrical configurations have been explored, such as parallel-connected LED segments with series-connected LED groups, each with current control circuits on the substrate adjacent to the LED segments. This allows for modular designs and improved thermal management.

FAQs

- What is the difference between COB and SMD LEDs?

COB LEDs have multiple chips mounted on a single board for intense, uniform light, while SMD LEDs offer flexibility and are used in various designs. - Are COB LEDs more efficient than traditional LEDs?

Yes, COB LEDs are highly efficient, converting more power into light with minimal heat loss. - How do COB LEDs handle heat?

COB LEDs are designed with advanced thermal management systems, ensuring efficient heat dissipation for optimal performance. - What are the common applications of COB LEDs?

They are used in spotlights, floodlights, industrial lighting, and automotive lighting, among others. - Can COB LEDs be dimmed?

Yes, COB LEDs can be dimmed with compatible drivers and dimmer switches.

To get detailed scientific explanations of COB LED, try Patsnap Eureka.